The perfect fit, Fast m-10 rear suspension adjustments – Polaris 340 Edge User Manual

Page 52

50

THE PERFECT FIT

FAST M-10 Rear Suspension Adjustments

Other Ride and Performance Settings

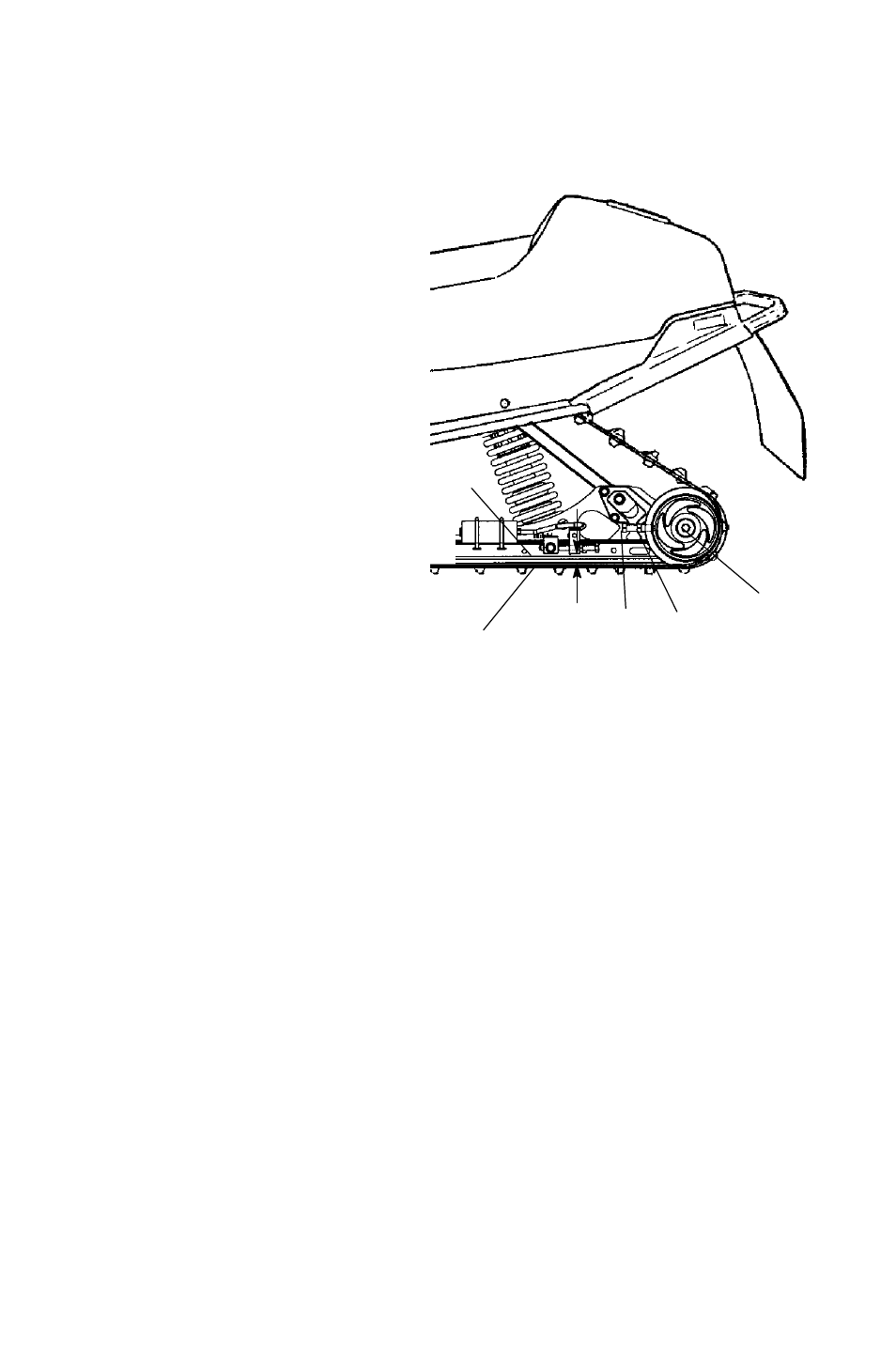

Track Tension

Track adjustment is critical

for proper handling. Always

maintain correct tension and

alignment. Tension

adjustments should be made

only after the track is

warmed up and limber.

1. Turn the machine off.

2. Lift the rear of the

machine and safely

support it off the ground.

3. Place a 10 lb. weight on

the track approximately

16” ahead of the rear axle

to slightly preload the

track.

4. Check for 7/8” - 1-1/8”

gap between the wear surface of the metal track clip and the plastic

hi-fax (C) . Measure at a point 16” ahead of the rear axle.

If the track needs adjustment:

5. Loosen the rear idler shaft bolts (D) and locknuts (A).

6. Tighten or loosen the track adjusting screws (B) as necessary to

provide equal adjustment on both sides of the track.

7. Tighten the locknuts (A). Then tighten the idler shaft bolts (D) to

35 ft. lbs. (47 Nm).

NOTE: Always inspect track alignment after track tension adjustment.

Track alignment affects track tension. Misalignment will cause

excessive wear to the track and slide rail. Excessive Hi-Fax wear will

appear on units with track tension set too tight. Refer to the Master

Repair Manual for track alignment procedure.

C

D

Track

Hi-fax

B

A