Maintenance, General maintenance – Polaris 340 Edge User Manual

Page 119

117

MAINTENANCE

General Maintenance

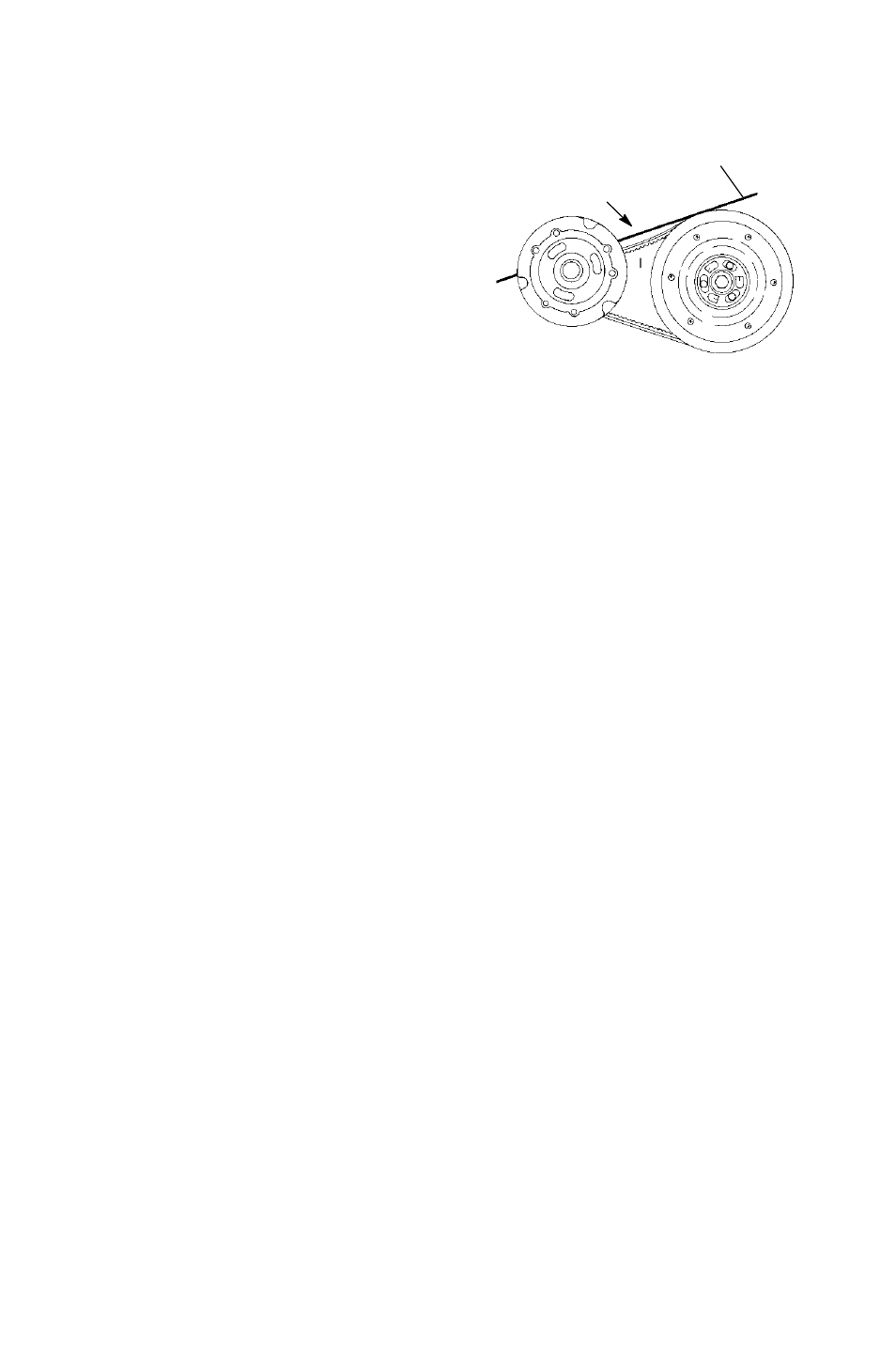

Drive Belt Deflection

Measure belt deflection with both

clutches at rest and in their full

neutral position.

Place a straight edge on the belt (A)

and apply downward pressure while

measuring at point B. This

measurement should be 1 1/4”.

Drive Belt Adjustment

Standard Clutch

Belt deflection can be adjusted without removing the clutch from the

jackshaft.

1. Pull the belt into the driven clutch to slightly open the sheaves.

2. Loosen the three bolts on the adjustment cam and turn the cam

counterclockwise to reduce the distance between the sheaves. Do

not rotate past the #1 position.

3. Torque the bolts to 4-6 ft. lbs. (5.4-8 Nm).

TEAM Clutch

1. Loosen the 7/16” jam nut on the belt width adjuster.

2. Using a 1/8” Allen wrench, adjust the threaded set screw as

needed. NOTE: Turn the set screw in (clockwise) to increase the

distance between the sheaves and out (counterclockwise) to

decrease the distance.

3. Tighten the jam nut.

Clutch Center Distance

See your Owner’s Manual Supplement for recommended center

distance for your machine. If adjustment is necessary, see your dealer.

Due to tolerances in belt length, it may be necessary for your dealer to

make minor adjustments in the driven clutch to achieve correct belt

tension.

A

B