Durawatt, Electric water heater, Electric water heater troubleshooting guide – PVI Industries PV 500-6 User Manual

Page 14

DURAWATT

®

ELECTRIC WATER HEATER

PV500-6 09/07

14

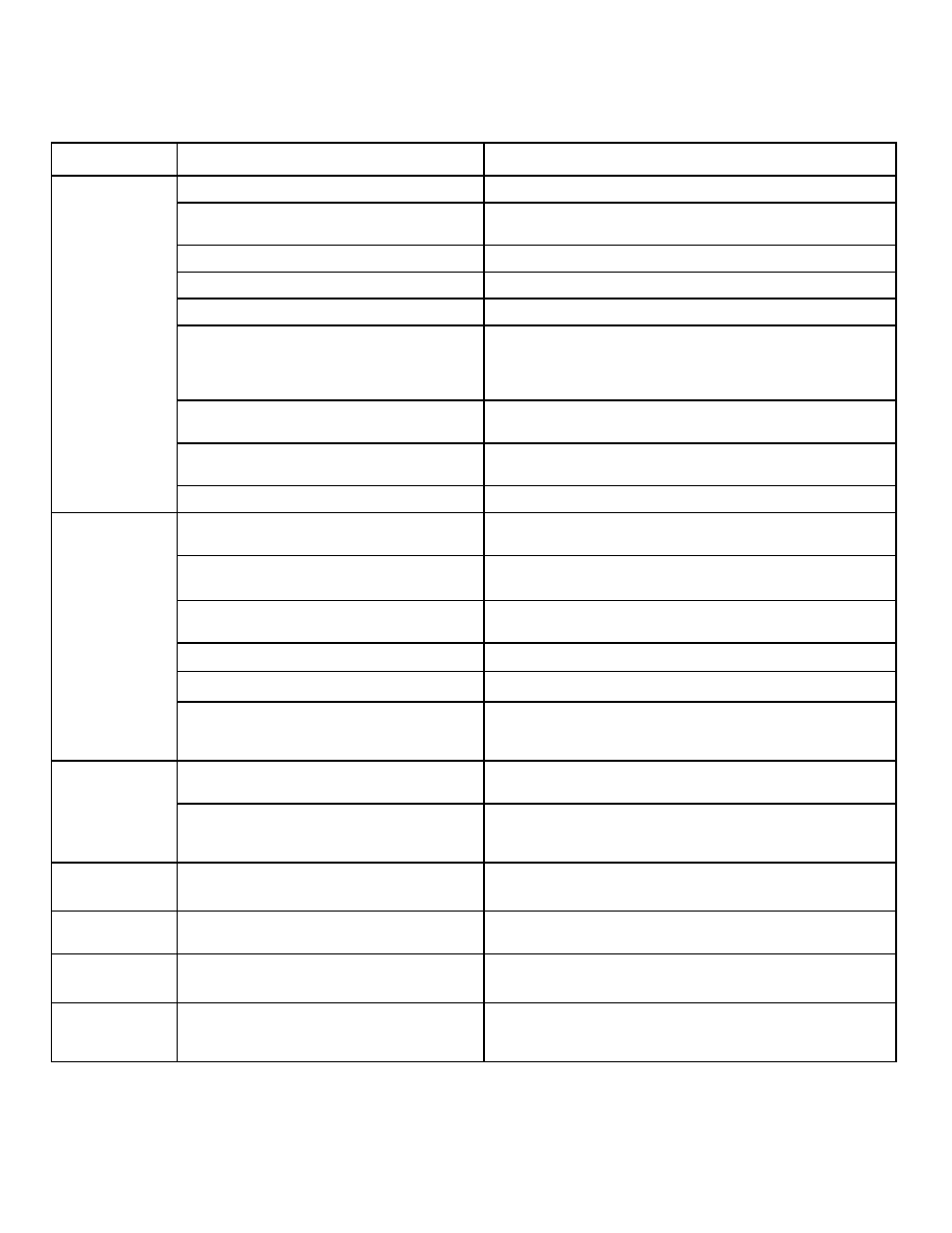

ELECTRIC WATER HEATER TROUBLESHOOTING GUIDE

TROUBLE PROBABLE

CAUSE

REMEDY

No hot water

Thermostat(s)

Check to assure proper thermostat setting.

Contractors will not pull in

Check continuity between all three thermostats or pressure

controls. Complete circuit. If one is open, it must be replaced.

Control circuit switch is in OFF position

Close switch. (Turn to ON position)

Control circuit fuse blown

Isolate cause for failure and replace fuse.

Contractor(s) coil open

Check continuity. Replace coil if not a complete circuit.

Time delay sequencer not operating

Check for 120 volts to coil on first sequencer step. Allow ample

time for additional steps to energize. If steps do not energize in

reasonable time, replace only the defective relay step. See

wiring diagram.

Proportional sequencer not operating

Check for 120 volts to line connection (L) on sequencer. Check

fuse for continuity. See wiring diagram. Consult factory.

Low water cutoff open

Check for open circuit. Check water level in tank. Replace low

water cutoff if defective.

Heating elements

Check for open legs. (See table 2).

Insufficient hot

water

Heater not large enough to satisfy peak

demands

Add booster or additional kw input. Consult local PVI

representative.

Hot water lines not insulated

Add insulation; it will protect against heat loss and save on cost

of operation.

Power fuse(s) blown

Check fuses for continuity. Replace if blown. If blown, determine

cause of break before replacing with same type fuse.

Contractor(s) not closing

Check coil for continuity. If defective, replace.

Thermostat(s) not correctly set

Check to assure proper thermostat control setting.

Element(s) not heating

Check for proper amperage draw. Check for proper ohm

resistance. Replace if defective. Consult factory.

(See table 1)

Burned or

discolored wires

Loose connections

Tighten all connections. If charred, replace wire with wire of

same type and size.

Dirty or pitted contactor points

Remove contactor points and inspect. If dirty, clean with emery

paper. CAUTION: Point must remain flat. If pitted or burned,

contractor points must be replaced.

Blown fuses

Loose connection. Defective element

Check all connections for tightness. Check ohm resistance in

electric elements. Replace.

High or low

voltage

Local utility

Check with local utility.

High or low

amperage

High or low voltage. Defective element

Check with local utility. Low amperage, check fuses, tighten

connections. Check ohm resistance on elements.

Wire burned

or melted at

element

Loose connections. Water leaking on elements

Tighten connection and replace wire. Isolate leaking water and

repair. Replace wire with same type and size.