Pride Mobility Jet 10 User Manual

Page 38

38

www.pridemobility.com

Jet 10/Rev H/Feb03

To inspect or replace the motor brushes:

1. Remove the seat and body shroud. See VII. Disassembly.

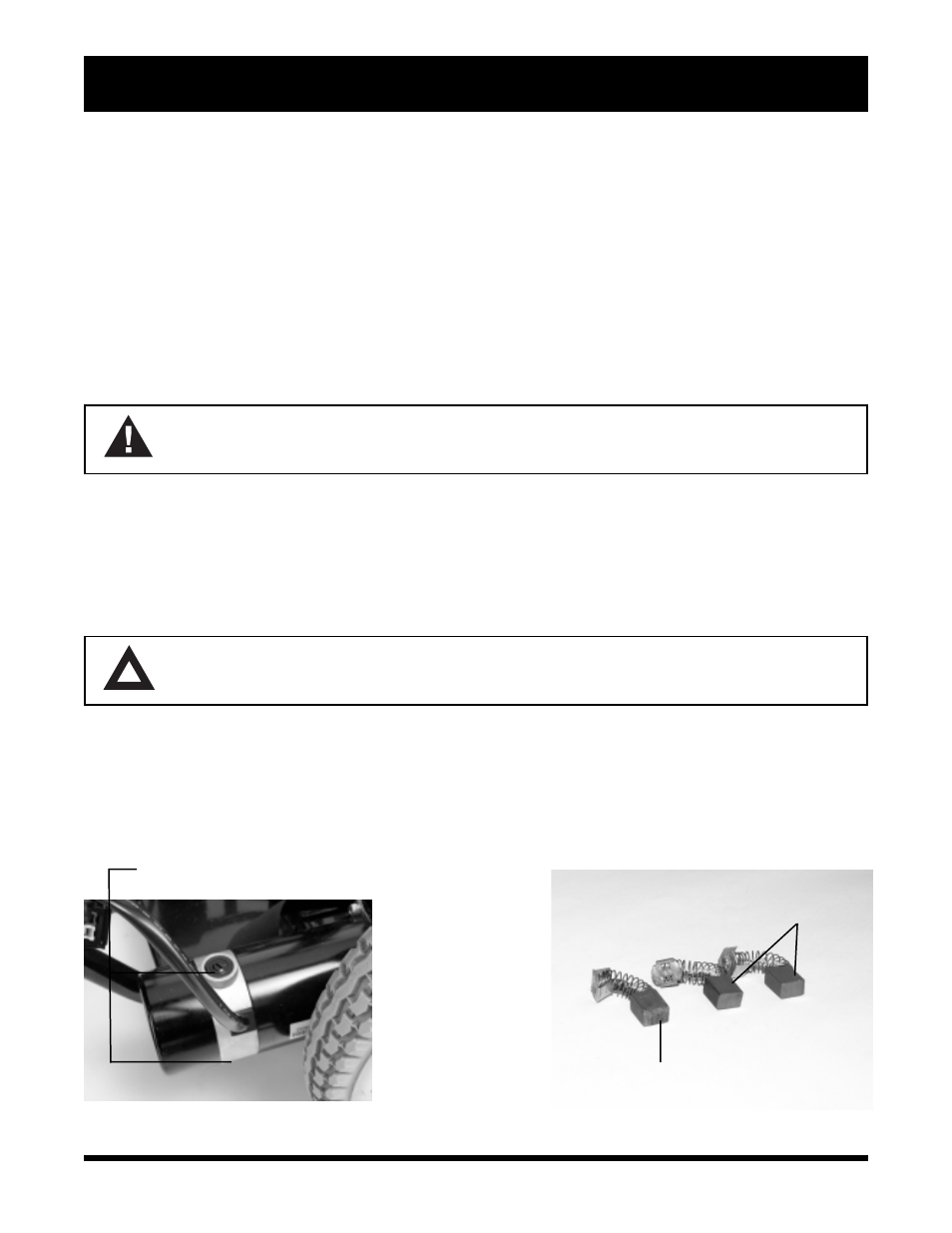

2. Unscrew the motor brush caps. See figure 27.

3. Remove the brushes.

4. Inspect for wear. See figure 28.

5. Replace brushes, if necessary. Contact your authorized Pride provider for replacement brushes.

X . C A R E A N D M A I N T E N A N C E

Figure 27. Motor

MOTOR BRUSH CAPS

Figure 28. Motor Brushes

NEW MOTOR BRUSH

WORN MOTOR

BRUSHES

The electric motors that power your Jet 10 use carbon brushes. These brushes may become susceptible to wear

over a long period of time. The motor brushes are the two contacts located inside the motor assembly that supply

power to the motor. They are designed to provide several thousand hours of operation. However, if the brushes

become dirty with carbon deposits or wear out, the motor will run poorly or not at all. We recommend that your

authorized Pride provider inspect the brushes every six months, or sooner if your Jet 10 runs poorly.

CAUTION! If inspection determines excessive wear on the brushes, they must be replaced or

motor damage will result. Failure to maintain the brushes could void the warranty.

MOTOR BRUSHES

11. Connect the wire marked (+) to the closest positive (red) battery terminal.

12. Connect the wire marked (-) to the closest negative (black) battery terminal on the other battery.

13. Connect one circuit breaker harness to the empty positive terminal of one battery, and connect the other circuit

breaker harness to the empty negative terminal of the other battery.

14. Retighten all nuts.

15. Replace the shroud and seat.

WHEN TO SEE YOUR AUTHORIZED PRIDE PROVIDER FOR SERVICE

The following symptoms could indicate a serious problem with your Jet 10. If necessary, contact your authorized

Pride provider. When calling, have the model number, serial number, nature of the problem, and the trouble code,

if available.

WARNING! Make sure you tighten the fasteners so that the connections are secure.