Handling information, Soldering, 2 soldering by dipping or by solder wave – Philips TDA6107AJF User Manual

Page 13: 3 manual soldering, 4 package related soldering information, Tda6107ajf, Philips semiconductors

9397 750 14728

© Koninklijke Philips Electronics N.V. 2005. All rights reserved.

Product data sheet

Rev. 02 — 28 April 2005

13 of 16

Philips Semiconductors

TDA6107AJF

Triple video output amplifier

13. Handling information

Inputs and outputs are protected against electrostatic discharge in normal handling.

However, to be completely safe, it is desirable to take normal precautions appropriate to

handling integrated circuits.

14. Soldering

14.1 Introduction to soldering through-hole mount packages

This text gives a brief insight to wave, dip and manual soldering. A more in-depth account

of soldering ICs can be found in our

Data Handbook IC26; Integrated Circuit Packages

(document order number 9398 652 90011).

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

14.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 seconds to 4 seconds at 250

°

C or 265

°

C, depending on solder material applied, SnPb

or Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

stg(max)

). If the

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

14.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is

less than 300

°

C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300

°

C and 400

°

C, contact may be up to 5 seconds.

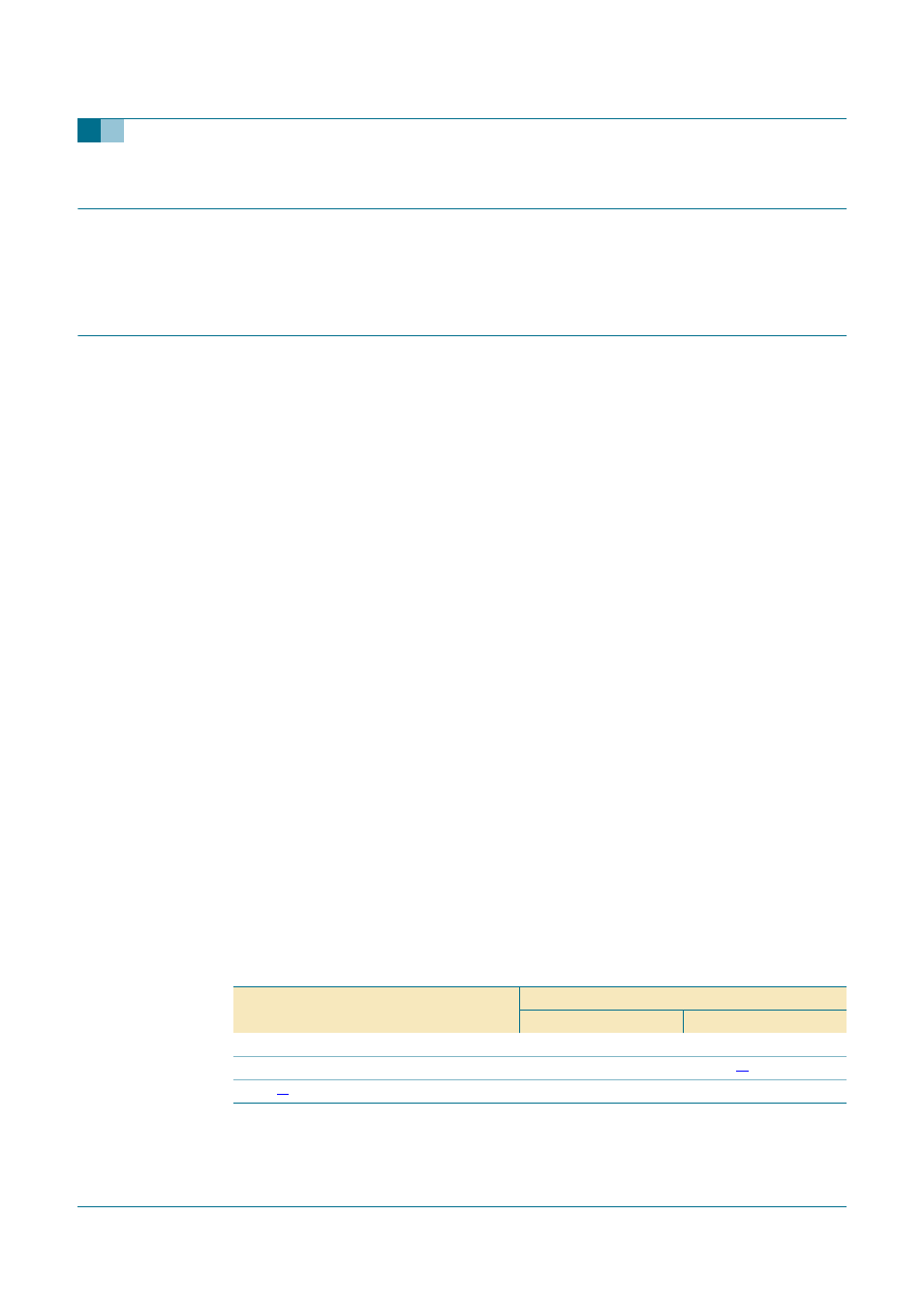

14.4 Package related soldering information

[1]

For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

board.

[2]

For PMFP packages hot bar soldering or manual soldering is suitable.

Table 6:

Suitability of through-hole mount IC packages for dipping and wave soldering

methods

Package

Soldering method

Dipping

Wave

CPGA, HCPGA

−

suitable

DBS, DIP, HDIP, RDBS, SDIP, SIL

suitable

suitable

[1]

PMFP

[2]

−

not suitable