PB Heat Gas/Oil Boilers User Manual

Page 25

control valve and boiler circuit pump piped off of

the system as a secondary loop. See Figure 3.6

for a single boiler and Figure 3.7 for multiple

boilers.

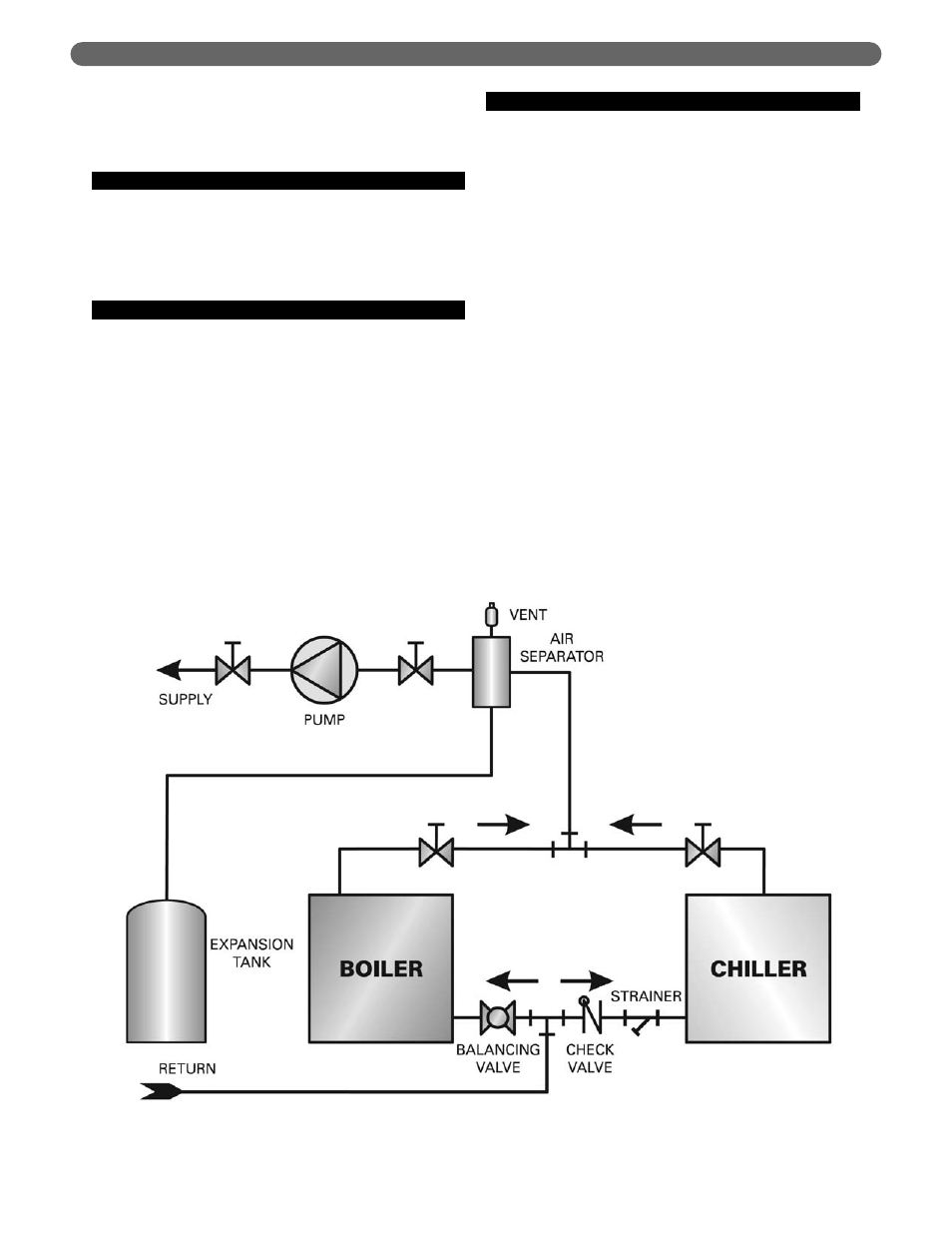

D. CHILLED WATER SYSTEMS

1. If the boiler will be used in conjunction with a

refrigeration system, the chilled medium must be

placed in parallel with the boiler and proper valves

applied to prevent the chilled medium from entering

the boiler. See Figure 3.5.

E. HIGH FLOW RATE PIPING

1. For flow rates higher than given in Table 3.1, provide

bypass piping around the boiler to limit the boiler

flow to that given in the table or pipe the boiler in a

secondary loop with its own pump as shown in

Figure 3.3.

F.

MULTIPLE BOILER INSTALLATIONS

1. For multiple boiler installations, piping the boilers in

a secondary loop is recommended. Each boiler

should be provided with its own pump and piped off

of the secondary loop header. See Figure 3.7 for

systems with return temperature above 130°F on gas

boilers or 150°F on oil boilers. For low temperature

systems, see Figure 3.4 (constant low temperature

systems) or Figure 3.8 (variable low temperature

systems).

2. You can use alternative piping if desired, such as

parallel piping or series piping in the primary system

loop. But these systems are less versatile.

a) With parallel piping, for instance, the system flow

conditions change if one or more of the boiler

shut-off valves are closed. It is difficult to pipe

parallel boilers to protect the boiler from low

return temperatures.

b) With series piping, temperature control to the

system is difficult because the temperature rise

equals the sum of the rises through each boiler.

Series piped boilers cannot be isolated for

servicing.

23

PIPE THE BOILER

Figure 3.5: Piping to Isolate Boiler from Chilled Medium on Chiller Systems