Pipe the boiler – PB Heat Gas/Oil Boilers User Manual

Page 22

A. PREPARATION

1. Make sure the boiler has been pressure tested as

outlined in “Place the Boiler Sections” in this

manual.

2. The Supply and Return piping can be installed

before installing the jacket. Use nipples long enough

to extend through the jacket.

3. Install a pipe plug or nipple and cap in the 3”

tapping in the top of the tapped intermediate section

when necessary. Use only the lower side connection,

required for return piping as shown.

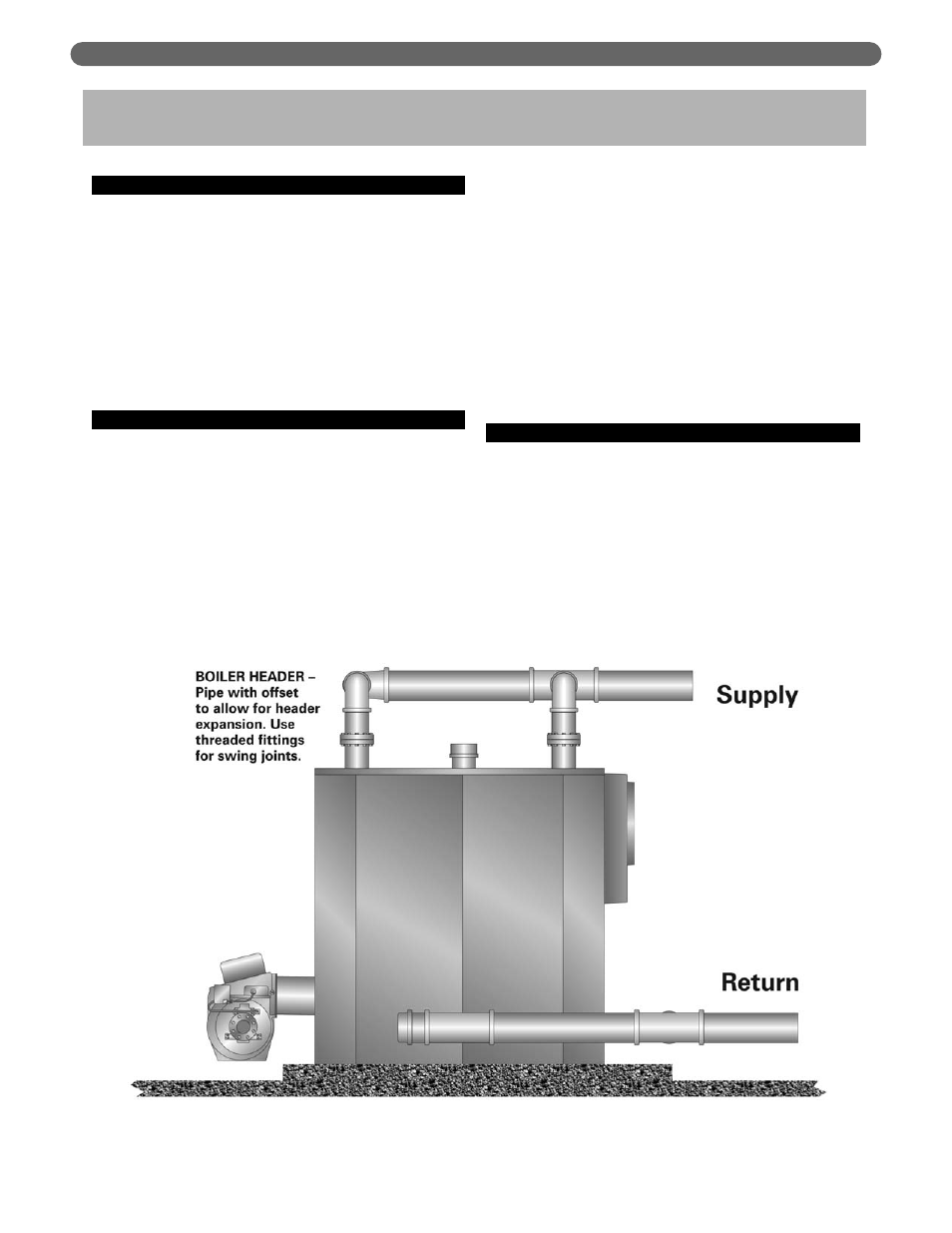

B. SUPPLY AND RETURN PIPING

1. Always locate the Supply and Return connections as

shown in Figure 3.1 and other illustrations in this

manual.

2. The suggested supply and return sizing in Table 3.1

and in the “Boiler Ratings and Dimensions” section

in this manual is based on a flow rate through the

boiler equivalent to a 20°F temperature rise (1 gpm

flow for each 10,000 Btu/Hr of boiler output). Using

higher flow rates is not recommended. This could

cause poor water flow distribution in the boiler.

Lower flow rates (higher temperature rise) are

acceptable provided the return temperature to the

boiler is at least 130°F on gas boilers and 150°F on

oil boilers to prevent condensation of flue gases.

3. Do not reduce the number or size of supply and

return connections given in Table 3.1. These are

required to control the flow velocities in the boiler

and maintain uniform distribution.

4. When the boiler is connected to heating coils located

in air handling units, the boiler piping system must

be equipped with flow control valves or other

automatic devices to prevent gravity circulation of

the boiler water during the cooling cycle.

C. LOW SYSTEM TEMPERATURE

1. Low Return Temperature Piping, General

a) When the return temperature from the system

will be below 130°F on gas boilers or 150°F on

oil boilers for extended periods (heat pump

systems, outdoor reset, snow melt, etc.), provide

piping and controls to protect the boiler from

condensation. Condensation will damage the

boiler and will lead to shortened boiler life and

maintenance problems.

20

3. PIPE THE BOILER

Figure 3.1: Piping Detail, Supply and Return Connections

PIPE THE BOILER