Poulan 172787 User Manual

Page 23

23

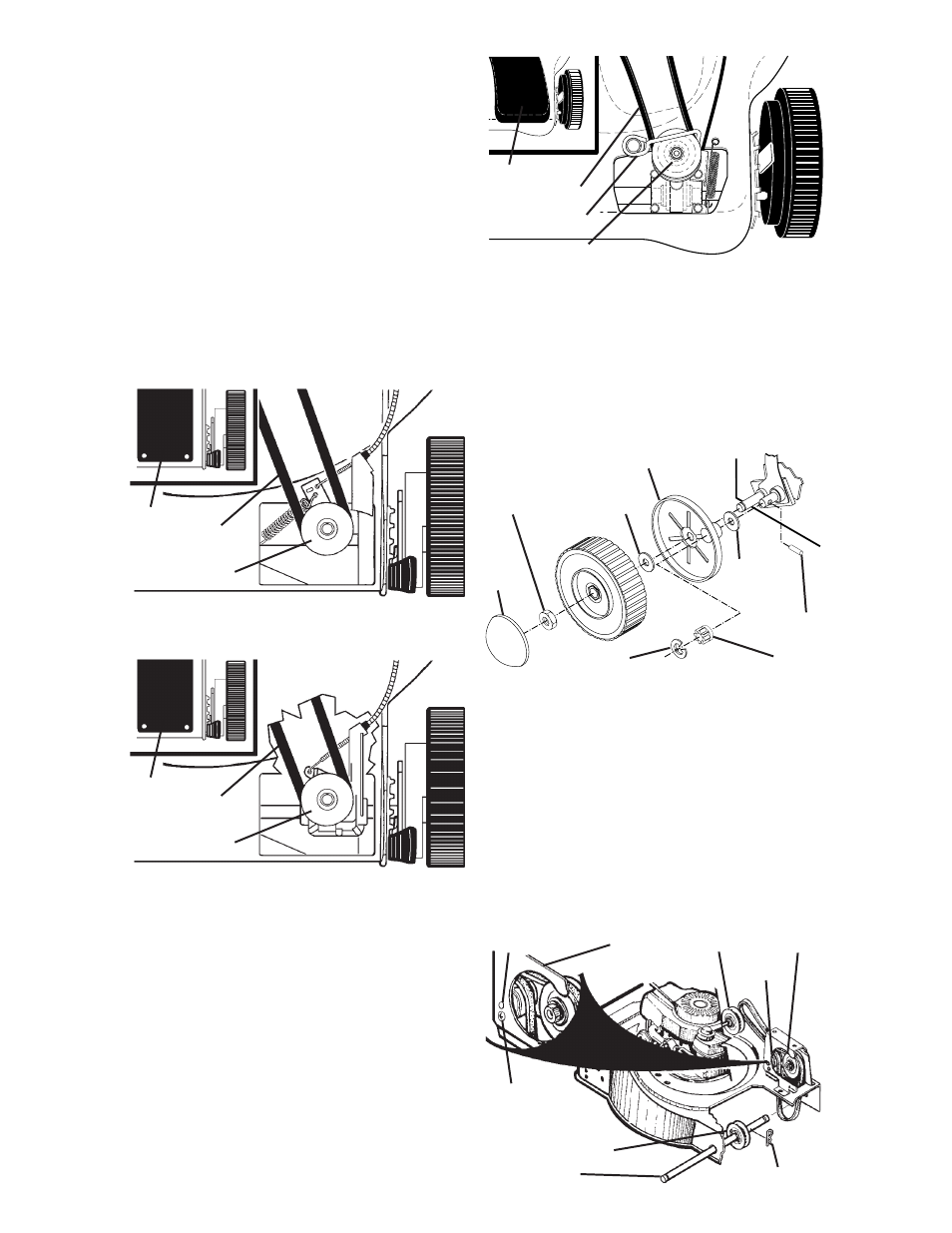

TO REMOVE / REPLACE DRIVE BELT

FRONT WHEEL GEAR DRIVE

• Remove drive cover. Remove belt from

gearcase pulley by pushing down on pul-

ley and rolling belt off it.

• Turn lawn mower on its side with air fi lter

and carburetor up.

• Remove blade.

• Remove debris shield.

• Remove belt from engine pulley on

crankshaft.

• Install new belt by reversing above steps.

NOTE: Always use factory approved belt to

assure fi t and long life.

Belt

Drive

cover

PUSH DOWN

Belt

Drive

cover

PUSH DOWN

GEAR CASE WITH PLASTIC HOUSING:

“AUTO WALK” OR “VARI-SPEED” ONLY

• Remove drive cover and belt keeper.

• Remove belt from gearcase pulley by

push ing down on pulley and rolling belt

off it.

• Turn lawn mower on its side with air fi lter

and car bu re tor down.

• Remove blade and debris shield.

• Remove belt from engine pulley on

crankshaft.

• Install new belt by reversing above steps.

NOTE: Always use factory approved belt to

assure fi t and long life.

Belt

Drive

cover

PUSH DOWN

Belt keeper

GEAR CASE WITH METAL HOUSING:

FRONT WHEEL BELT DRIVE

• Remove drive cover by removing screw

at rear of cover.

• Remove belt from drive pulley.

• Remove hubcaps and nuts from both

front (drive) wheels. Remove wheels

and washers from wheel adjusters.

• At left (drive) wheel only, remove E-ring, pin-

ion, roll pin, felt washer and dust cover.

Felt

washer

Nut

Washer

Dust cover

Roll pin

E-ring

Pinion

Hub

cap

Drive shaft

Upper adjust-

ment hole

Lower hole

(original and

new belt

position)

Drive

pulley

Driven

pulley

Clutch

pulley

Retainer clip

Clutch

frame

Idler

• Remove retainer clip from drive shaft on

left side of driven pulley.

• While holding driven pulley, slide drive

shaft to the right until belt can be re-

moved from opening in housing.

• Pull belt free from idler and take out of

clutch frame.

• Reverse procedure to install new belt.

NOTE: When re-assembling pinion, be sure

that the felt washer is in place behind the roll

pin and that the roll pin is seated in the slots

on the bearing and in the back of the pinion.