Powermatic 2013 User Manual

Page 30

30

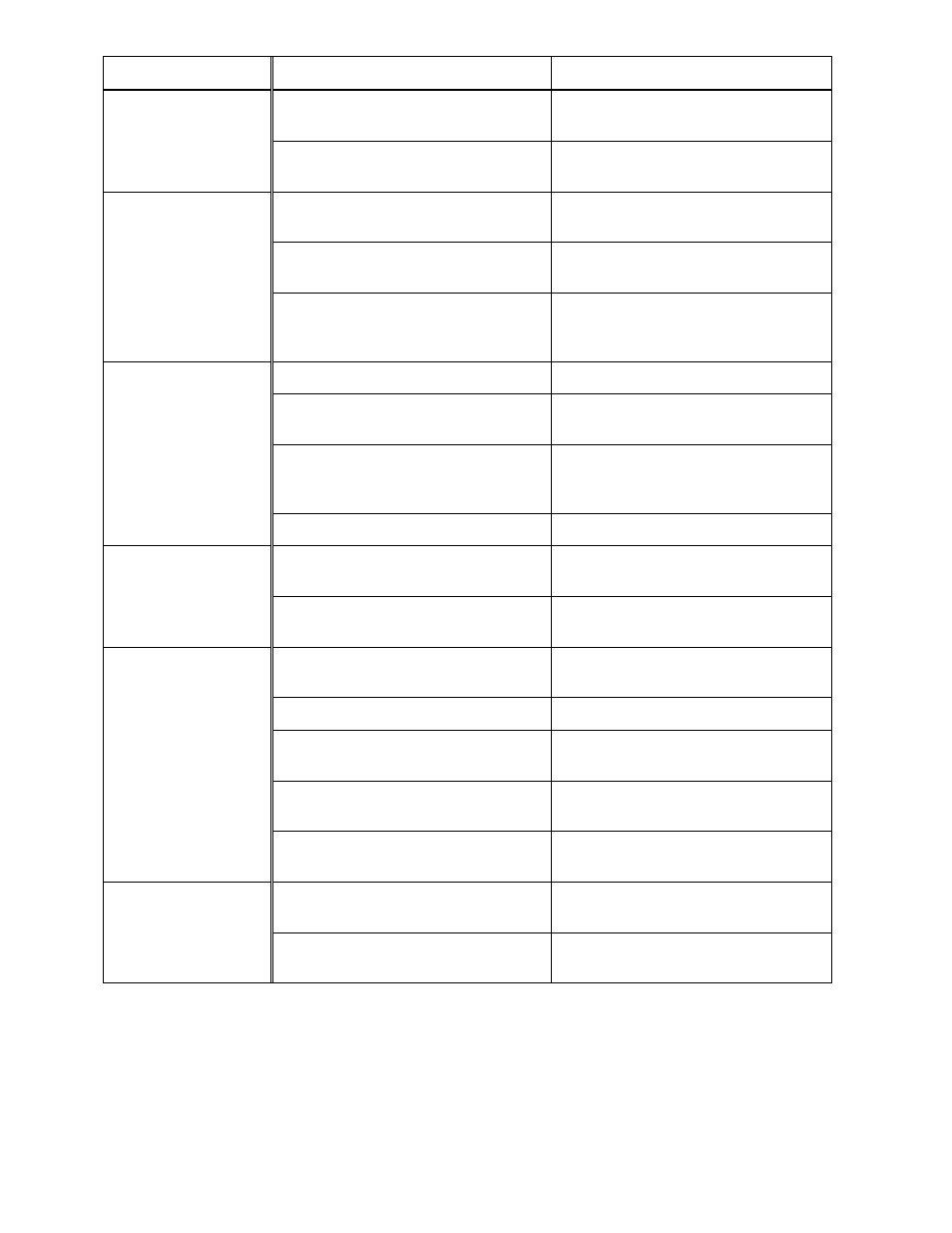

Trouble Probable

Cause

Remedy

Blade sharpened incorrectly,

becomes overheated.

Sharpen blade properly or replace.

Blade forms cracks at

base of teeth.

(continued)

Band wheels have become

misaligned.

Contact service representative.

Workpiece being fed too quickly.

Reduce feed speed to lessen strain

on the blade.

Welding on blade not perfectly

aligned.

Eliminate the welded part, and re-

weld properly; or acquire a new blade.

Cracks on back edge

of blade.

Support bearing is worn; caused by

constant contact with back of blade.

Replace support bearing. Adjust new

bearing according to instructions (see

pages 18 and 19).

Feed force too great.

Reduce feed force.

Blade pitch too coarse.

Refer to blade selection chart; use

finer pitch blade (see page 28).

Support bearing not properly

supporting blade.

Check support bearing for correct

position and signs of wear. Adjust or

replace as needed.

Blade breaks

prematurely.

Blade tensioned too tightly.

Reduce tension (see page 16).

Blade overheated during welding.

Have blade annealed, or eliminate

brittle part and weld correctly.

Blade breaks close to

weld.

Blade cooled too rapidly after welding.

Have blade annealed, or eliminate

brittle part and weld correctly.

Blade “pitch” too fine.

Refer to blade selection chart (page

28). Use blade with coarser pitch.

Feed pressure too light.

Increase feed pressure.

Cutting rate too low.

Increase feed pressure and cutting

rate.

Incorrect choice of blade.

Re-examine material. Select proper

blade from the chart (page 28).

Premature dulling of

saw teeth.

Chipped tooth or foreign object

lodged in cut.

Stop the saw and remove lodged

particle. Replace blade if damaged.

Incorrect blade tension or damaged

blade.

Correct accordingly.

Blade binds in the

workpiece.

Blade too wide for desired radius.

Select narrower blade. See chart on

page 28.