Operating controls – Powermatic 2013 User Manual

Page 21

21

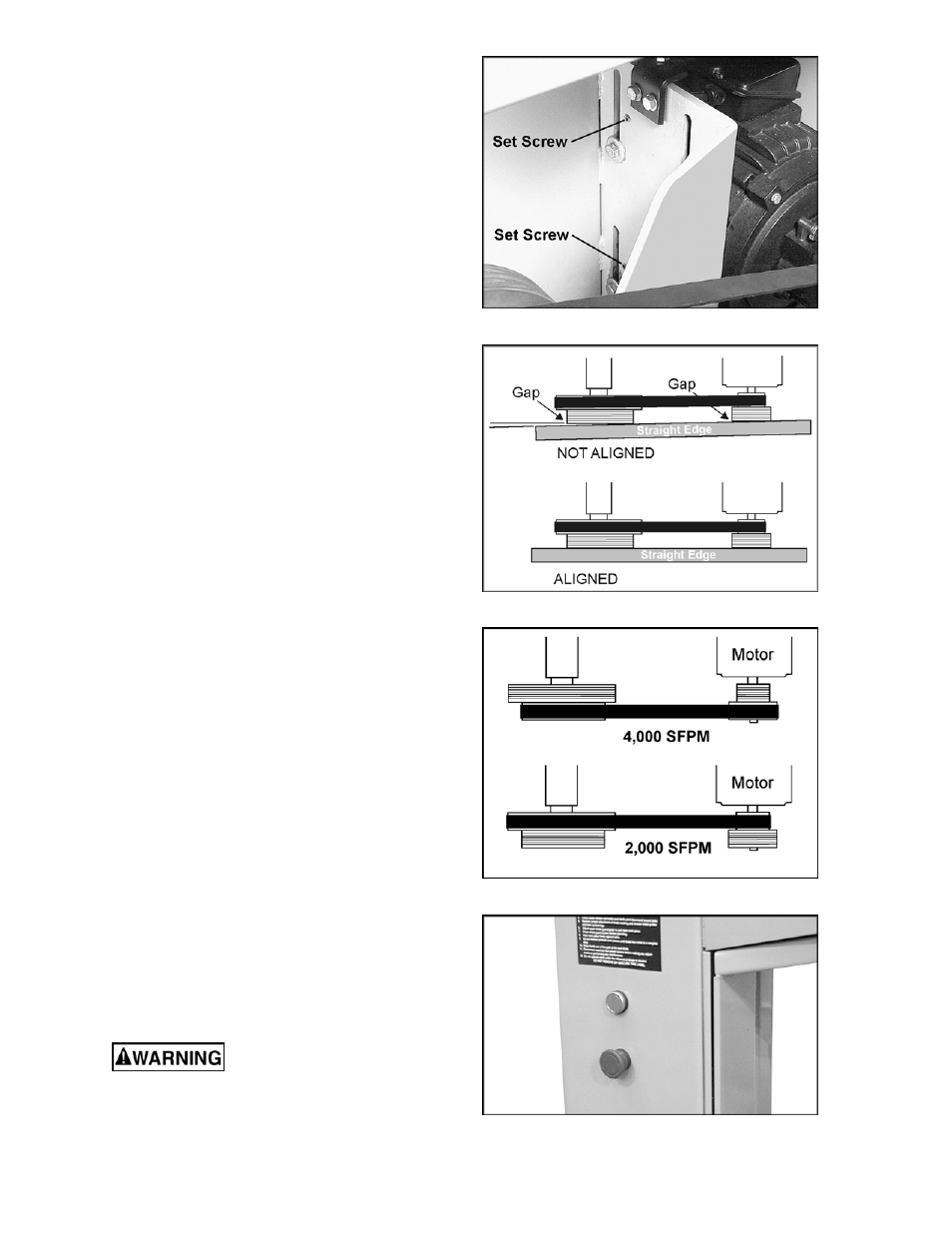

Belt Alignment

If the drive belt is not aligned properly, it can be

aligned with one or more of the four set screws

located behind the steel plate. Figure 25 shows

two of the set screws.

1. Loosen the four hex nuts (A, Figure 23)

2. Rotate clockwise one of the set screws

(Figure 25) with a 4mm hex wrench, to push

out the motor plate at that point. This will

shift slightly the angle of the motor. Use

whichever set screw is most effective in

adjusting the angle of the motor until the

drive belt is aligned.

3. Confirm the alignment of the drive belt by

placing a straight edge against the faces of

both pulleys, as shown in Figure 26. If the

straight edge lies flush against both pulleys,

then the pulleys and belt are aligned.

4. Re-tighten the four hex nuts (A, Figure 23).

Blade Speed Adjustment

The bandsaw will operate at 2,000 or 4,000

SFPM (surface feet per minute). Figure 27

shows the appropriate belt position to achieve

each speed.

To change the speed:

1. Disconnect machine from power source.

2. Loosen the four hex nuts (A, Figure 23) and

rotate the tension screw (B, Figure 23)

counterclockwise to release tension on the

belt.

3. Slide the belt onto the appropriate set of

pulleys (Figure 27). Make sure the belt is

aligned properly.

4. Re-tension the belt (see under “Belt

Tension”) and securely tighten all four hex

nuts on the motor plate (A, Figure 23).

Operating Controls

The START (green) and STOP (red) control

buttons are mounted to the column (Figure 28).

After the STOP button has been pushed, it

remains engaged. Rotate the STOP button

clockwise to release it. The Band Saw can now

be restarted with the START button.

After the machine is shut off,

allow the wheels and blade to come to a

complete stop before opening the doors,

making adjustments, or leaving the area.

Figure 25

Figure 26

Figure 27

Figure 28