Powermatic 2013 User Manual

Page 18

18

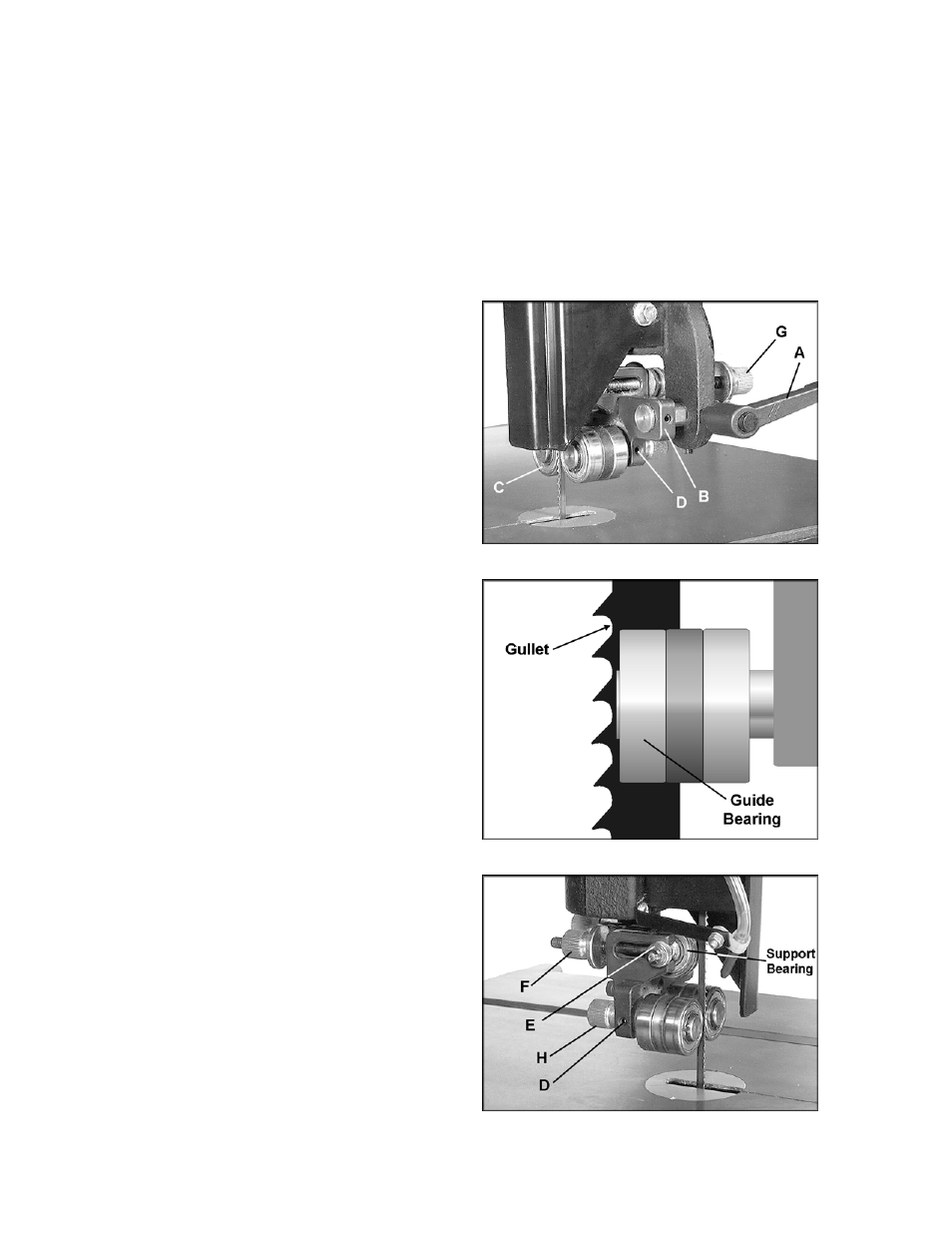

Upper Blade Guide Assembly

1. Disconnect machine from power source.

2. Loosen lock knob (see B, Figure 14) and

raise or lower upper blade guide assembly

by turning the handwheel (C, Figure 14).

3. Position the blade guide assembly about

3/16” above the material to be cut. The

scale (J, Figure 14) shows the distance from

bottom of upper blade guides to the table

surface.

4. Tighten lock knob (B, Figure 14).

Upper Blade Guides and Upper

Support Bearing

To adjust the bearing guides for proper blade

control, proceed as follows.

1. Disconnect machine from power source.

2. Blade must already be tensioned and

tracking properly.

3. Loosen the locking handle (A, Figure 17).

4. Adjust the guide bracket (B, Figure 17) by

rotating knob (G, Figure 17) until the front of

the guide bearings (C, Figure 17) are just

behind the blade’s gullet (curved area at the

base of the tooth). See Figure 18.

5. Tighten the locking handle (A, Figure 17).

6. Loosen set screw (D, Figure 17) on the

guide bearing assembly, with a 3mm hex

wrench. (Figure 17 shows the set screw for

the right hand bearing; the set screw for the

left hand bearing is shown in Figure 19.)

7. The guide bearing rotates on an eccentric

shaft. Adjust the guide bearing, by rotating

the knob (H, Figure 19) until the guide

bearing rests lightly against the blade. Do

not force the guide bearing against the side

of the blade.

8. Tighten set screw (D, Figure 17).

9. Repeat the process for the other guide

bearing. After adjustment, make sure the set

screw (D, Figure 19) is tightened.

10. Loosen nut (E, Figure 19).

11. Adjust the support bearing using the knob

(F, Figure 19) until the space between the

support bearing and the back edge of the

blade is approximately 1/64”. A convenient

way to achieve this spacing is by placing a

dollar bill folded twice (four thicknesses of a

dollar bill is approximately 1/64”) between

blade and support bearing.

Figure 17

Figure 18

Figure 19