Grounding instructions – Powermatic 2013 User Manual

Page 12

12

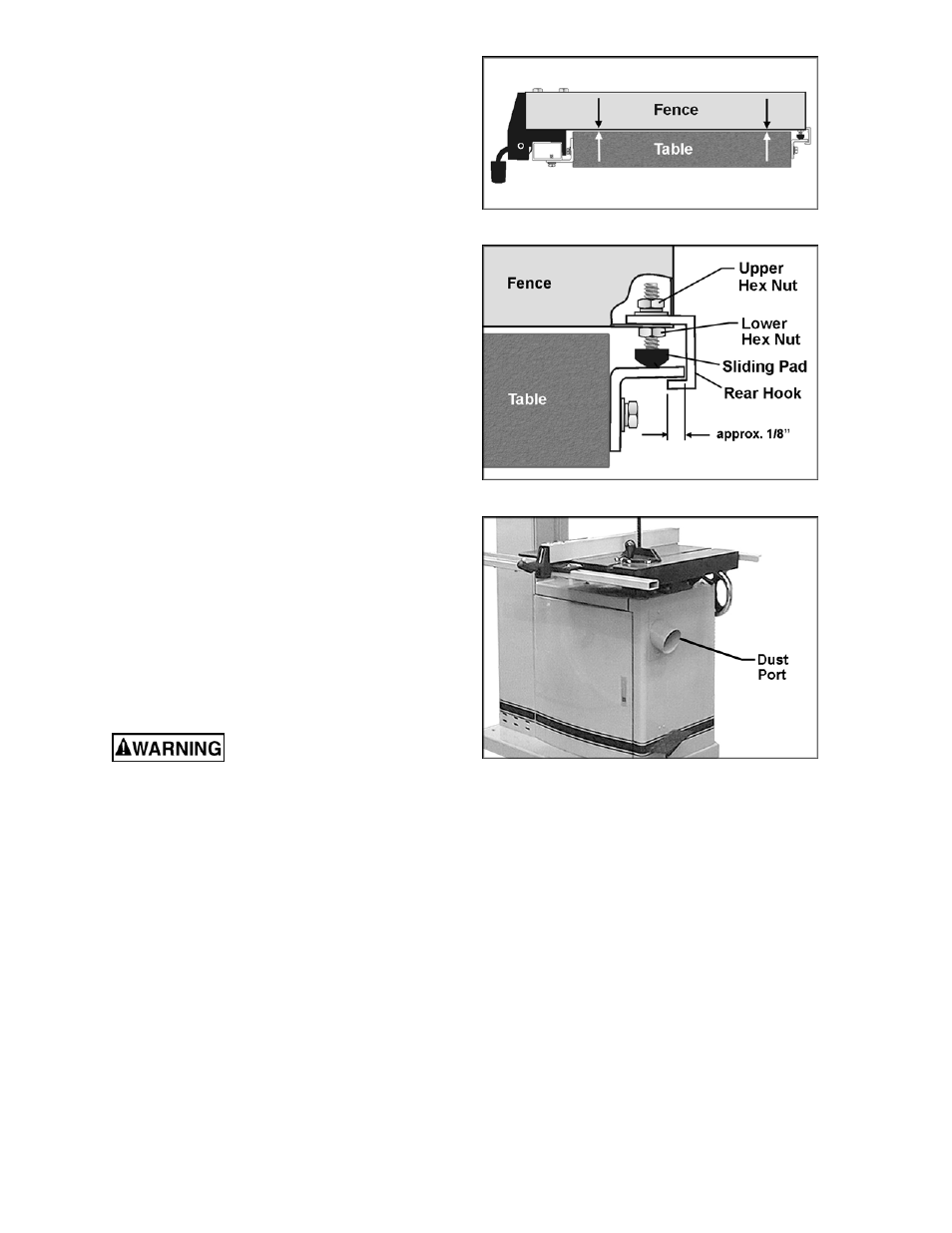

14. Check the clearance between the table and

the fence. The fence should not rub against

the table surface but be slightly above it.

This gap should be the same at the front of

the table as it is at the rear. See Figure 4.

15. If the gap between fence and table is not

consistent, loosen either of the hex nuts on

the hook (Figure 5) and rotate the sliding

pad until the fence/table gap is consistent

across the full length of the table. When this

is achieved, tighten both hex nuts.

16. Check the adjustment of the hook at the

rear of the fence. The hook should be

positioned so that it overlaps the rear rail by

approximately 1/8”. See Figure 5. To adjust

the hook, loosen the upper hex nut (Figure

6) and slide the hook in or out as needed.

Re-tighten upper hex nut.

Dust Collection

The use of a dust collection system is strongly

recommended for this band saw. It will help

keep the shop clean as well as reduce any

potential health hazards caused by inhalation of

wood dust. The collector should have a capacity

sufficient for this size machine (minimum of 600

CFM).

Attach the hose of the dust collector to the 4”

dust port below the band saw table (Figure 6).

Secure with a hose clamp or duct tape.

NOTE: Dryer vent hose is not acceptable for

wood dust collection.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This machine must be grounded. In the event of

a malfunction or breakdown, grounding provides

a path of least resistance for electric current to

reduce the risk of electric shock.

Improper connection of the equipment-

grounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipment-

grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Figure 4

Figure 5

Figure 6