English, Compact 2, 37 installation data – Protec Protech Compact2 Film Processor SX 2 User Manual

Page 37

COMPACT 2

TM

37

Installation Data

English

®

1

Mains (208) 220 - 240 V, 16 A; Cu wire-Kabel 3 x 1.5 mm

2

; Ground-Leakage-

Switch 25 A / 30 mA; power consumption 2.2 kW.

2a Power switch 16 A; 140 cm above floor;

2b Machine connection: Socket incl. earth 60 cm above floor.

3a Water connection: Water consumption 1.9 l/min; Water temperature may not

be below 5°C;

3b Water stop cock 3/4" washing machine connection.

4

Ventilation of darkroom is necessary.

5

Drainage hose, diameter 50 mm, acid resistant; odour preventor with connec-

tion for 10 mm hose.

6

Drainage for Developer; connection for 10 mm hose. Respective collecting

containers have to be supplied. Local water board regulations have to be

complied with!

7

Drainage for Fixer; connection for 10 mm hose. Respective collecting contain-

ers have to be supplied. Local water board regulations have to be complied

with!

8

Sink with hot/cold water and flexible hose; Inner dimensions are 60x40x30 cm

deep; Material: ceramics, stainless steel, plastics.

9

The replenishment containers can be placed under the processor or can be

installed externally.

10 Wall break through for film exit through the wall infeed (

page 35

): Processor is

installed outside the darkroom, the film exits into the light-room. For the alter-

ation “Through the wall mounting infeed” the assembly kit no. 1280-0-0000 is

necessary..

11 Wall break through for film exit through the wall output (

page 36

): Processor is

installed inside the darkroom, the film exits through the wall to the light-room.

For the alteration “Through the wall mounting film output” the assembly kit no.

1281-0-0000 is necessary.

Film exit through the wall

On machines which have the film exit through the wall into the light room, the fol-

lowing modifications have to be made:

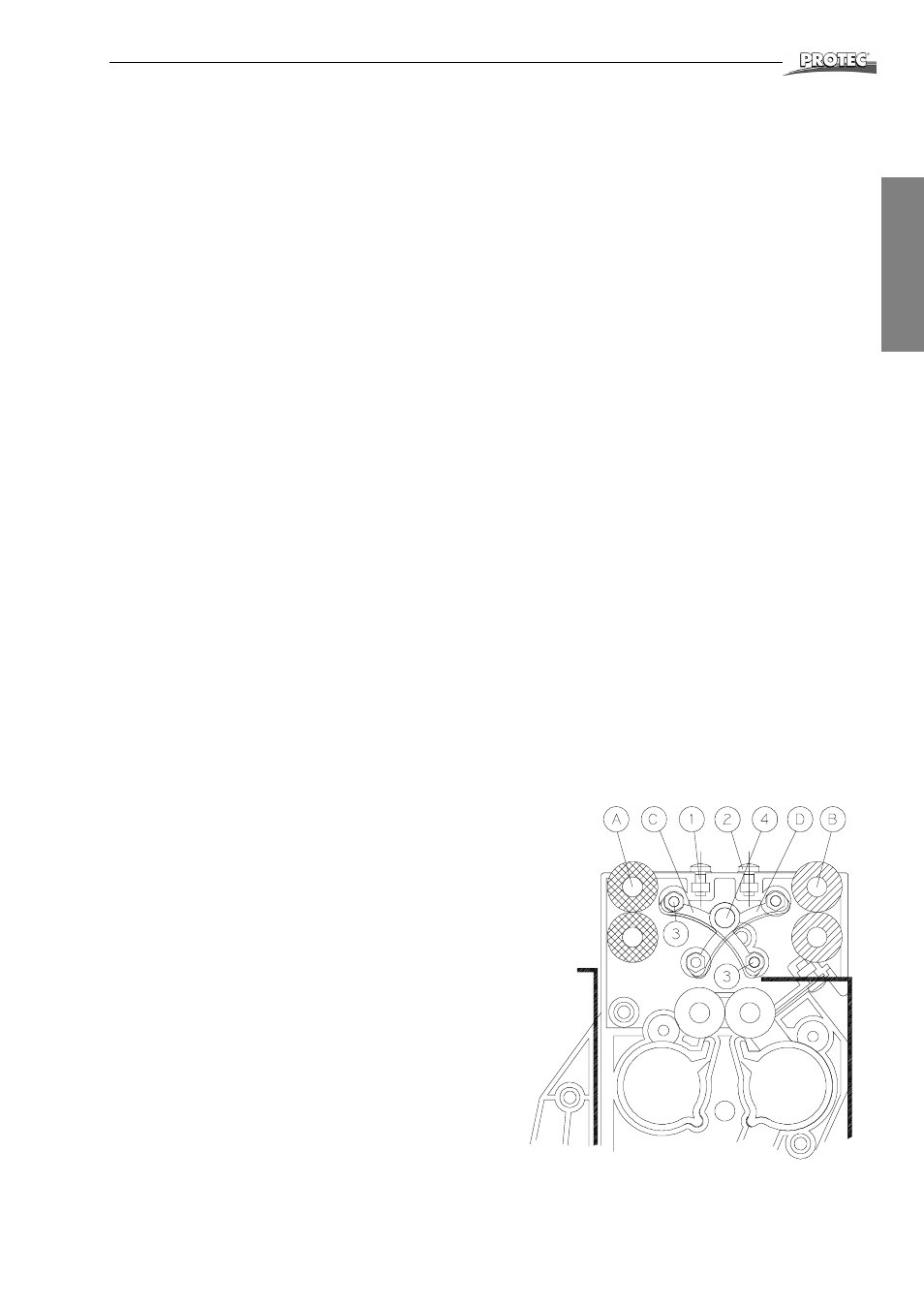

Dryer rack

Remove the two rollers from pos. A. To do this open bolt from

spring at pos. 1 and remove gear from lower roller.

Move curved guide bar from pos. C to D. To do this open bolt 3

and 4.

Install the two rollers in pos. B. Mount spring at pos. 2.

Machine cover

The front film exit opening in the machine cover has to be closed

with the screen contained in the assembly kit.

For the alteration “Through the wall mounting film output” the

assembly kit no. 1281-0-0000

page 48

is necessary.