Powermate P1204 User Manual

Page 17

17

200-2667

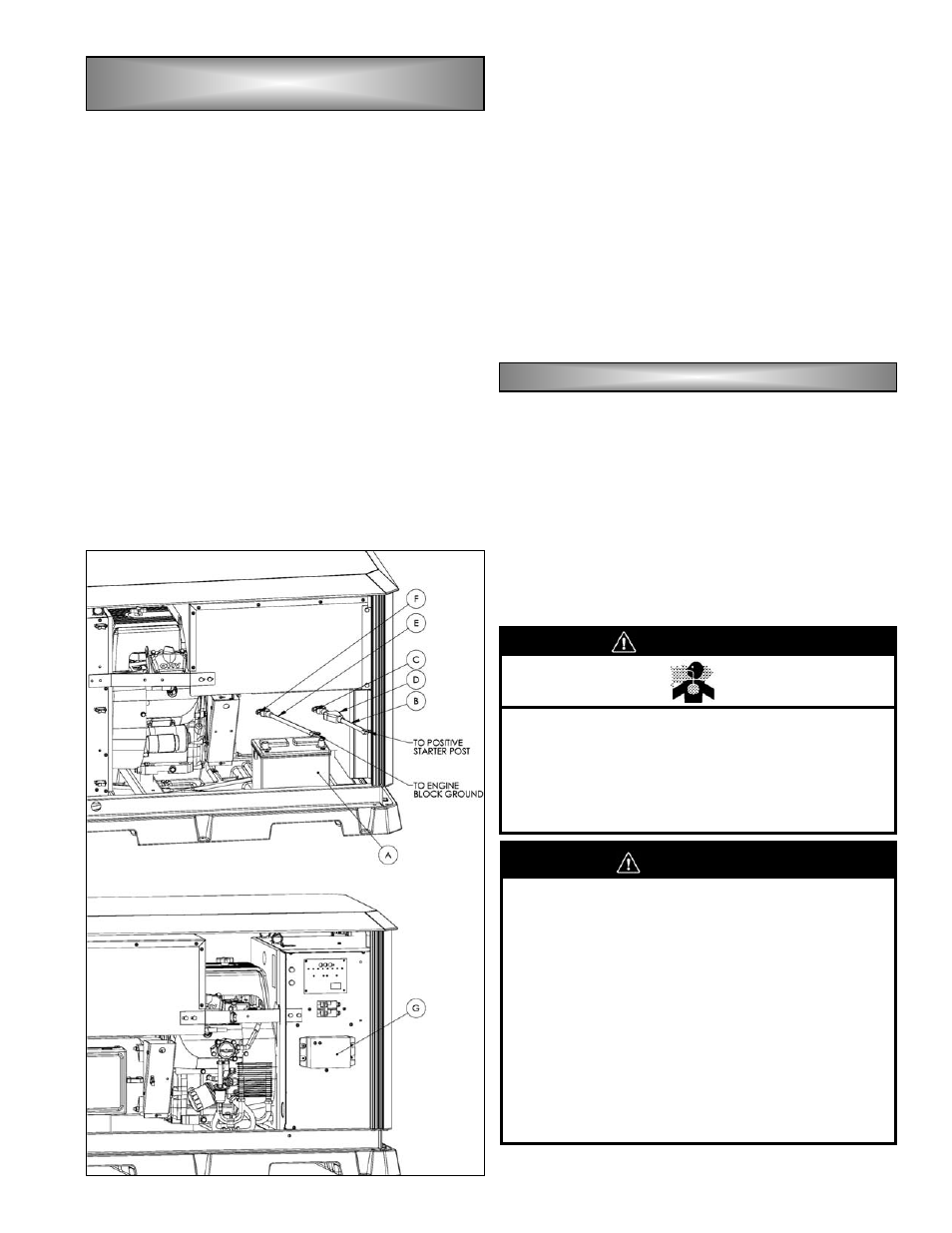

To access the battery and charger, remove the front

and back panels by inserting the key into the locks

located on top of the panel. and turn 1/4 turn

counterclockwise to unlock. Lift the panels up and out of

the base and set it aside.

Place the battery (A) on the base as shown in Fig G.

After the battery is set, begin attaching the battery

cables to the battery posts, starting with the positive (+),

or red, cable (B). Loosen the bolt (C) on the post clamp

slightly to allow the clamp to expand, then firmly push the

clamp onto the battery post marked positive (+) until the

top of the post extends past the top of the clamp. Rotate

the clamp around the post as required to insure the

clamp cannot contact any metal components, then

tighten the clamp bolt (C) until snug. Finally,slide the

post boot (D) down the cable and place it entirely over

the clamp.

Finish connecting the battery by placing the negative

(-), or black, battery cable (E) to the battery post marked

negative (-). Push the clamp firmly over the post until the

post extends past the top of the clamp, then rotate the

clamp to avoid contact with any metal parts. Tighten the

battery clamp bolt (F) until snug.

The final step of battery installation is to verify proper

connection of all battery charger connections. A battery

charging system (G) is included with the

engine/generator set to maintain the battery charge

during extended periods of generator inactivity, therefore

providing consistent starting. A quick check of charger

connections will verify that factory connections are

correct so the charger can function as intended. Insure

that the charger is connected by checking to see that it is

plugged into a powered receptacle, and that the positive

(+) and negative (-) charger cables are connected to their

respective battery cables.

Install the panels back onto the generator by placing

the bottom of the panel onto the base and pushing it up

into place. Lock the panel by inserting the key into the

locks and turning 1/4 turn clockwise.

Once all connections are made, the final installation

step is verification of proper engine oil level. Check oil

level before start-up (see page 23 for instructions). The

unit is shipped with the proper type of oil in the

crankcase for operation above 40°F. Follow the engine

manufacturer’s recommendations for oil at temperatures

below 40°F. Check oil periodically to ensure that the unit

is properly lubricated. Follow the engine manufacturer’s

recommended service schedule.

Engine oil capacity is 1.2 qt (1.14L) without a filter

change and 1.5qt (1.42L) with a filter change.

B

B

B

B

A

A

A

A

T

T

T

T

T

T

T

T

E

E

E

E

R

R

R

R

Y

Y

Y

Y

P

P

P

P

L

L

L

L

A

A

A

A

C

C

C

C

E

E

E

E

M

M

M

M

E

E

E

E

N

N

N

N

T

T

T

T

A

A

A

A

N

N

N

N

D

D

D

D

C

C

C

C

O

O

O

O

N

N

N

N

N

N

N

N

E

E

E

E

C

C

C

C

T

T

T

T

II

II

O

O

O

O

N

N

N

N

((

((

c

c

c

c

o

o

o

o

n

n

n

n

tt

tt

..

..

))

))

L

L

L

L

U

U

U

U

B

B

B

B

R

R

R

R

II

II

C

C

C

C

A

A

A

A

T

T

T

T

II

II

O

O

O

O

N

N

N

N

FIG. G

W

WA

AR

RN

NIIN

NG

G

•

State and federal agencies have determined

that contact with used engine oil can cause

cancer or reproductive toxicity. Take care to

limit skin contact and breathing of vapors as

much as possible. Use rubber gloves and wash

exposed skin.

C

CA

AU

UT

TIIO

ON

N

•

Too much oil can cause high oil consumption,

high operating temperatures and oil foaming.

Too little oil can cause severe engine damage.

Keep the oil level between the full and add

marks on the dipstick.

•

Any attempt to crank or start the engine before

it has been properly serviced with the

recommended oil will result in an engine failure

that is not covered under warranty.

•

Never run this equipment without the complete

air cleaner system installed on the engine.

Failure to do so will result in premature engine

wear and significantly reduced engine life.