Quickdraw, Steam heater – PVI Industries PV500-25 User Manual

Page 11

QUICKDRAW

Steam Heater

11

PV500-25 06/12

7.4 Tank

Scale will normally form in the tank during operation and will accumulate on the bottom of the tank. The natural

chemicals in the water forms scale which precipitate out during the heating cycles. Some water supplies contain

more of these chemicals than others do, and the scale buildup will occur more rapidly. Other factors affecting the

scale buildup are the amount of hot water used and the temperature of the water. The more hot water used the

more fresh water containing the scale-forming chemicals enter into the tank. As the temperature of the water

increases, the rate of scale deposited also increases. The frequency of inspections will be determined by the rate of

scale buildup. Until the appropriate inspection and cleaning frequency is established, initially inspect the tank every

six months or more frequently if higher scaling conditions are present.

Flush the tank at two or three-month intervals depending on water conditions in your location to help prevent the

accumulation of scale. To flush: turn off electrical disconnect switch to prevent the unit from operating. Open the

drain valve and allow water to flow through the tank until it runs clear. Close the drain valve and turn the electrical

switch back on.

NOTICE:

Since PVI cannot control the use of the water heater, water conditions, or maintenance, the warranty on

the water heater does not cover poor performance, structural failure, or leaking due to an excessive accumulation

of scale.

7.5

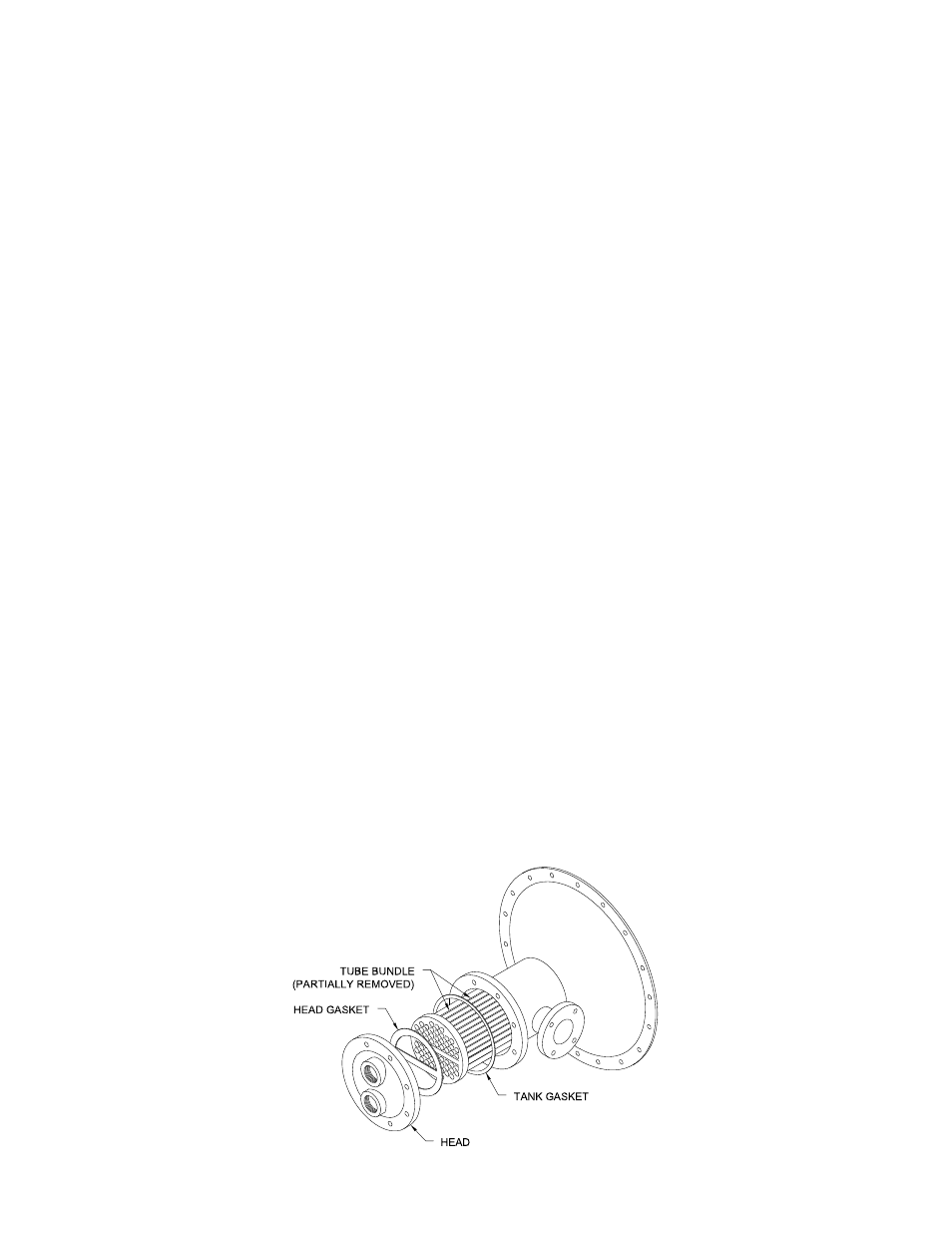

Cleaning the Heat Exchanger (refer to figure on page 11)

1. Do not open until all pressure is removed, the unit is drained and the equipment surfaces cooled to ambient

temperature.

2. Heat exchangers subject to fouling or scaling should be cleaned periodically. A light sludge or scale coating on

the tube greatly reduces its effectiveness. A marked increase in pressure drop and/or reduction in performance

usually indicate cleaning is necessary.

3. Tube bundle removal:

a. When practical, leave tube bundle attached to collar assembly and remove by unbolting collar assembly

from tank.

b. During bundle removal, the dead weight of the bundle should never be supported on individual tubes or

contact any lined interior tank surface. Following removal, rest the bundle on the tube sheet, support plates,

or wood blocks cut to fit periphery of the bundle.

c. Tube bundles may be raised using slings formed by bending light sheet metal into a “U” form and attaching

lifting lugs to the ends of the sheets. Baffles can be easily bent and damaged if dragged over rough

surfaces.

d. Before reinserting the tube bundle into the unit, place the ring/tank gasket over the end of the tube bundle

and bring forward to the backside of the tube sheet.

CAUTION: When cleaning a tube bundle, tubes should not be hammered on with any metallic tool and, in case it is

necessary to use scrapers, care should be exercised that the scraper is not sharp enough to cut the metal of the

tubes.