Powermatic 3520B User Manual

Page 25

25

Turn off the lathe and use a brush or paper

towel to apply the finish. Remove excess finish

before restarting lathe. Allow to dry and sand

again with 320 or 400 grit sandpaper. Apply

second coat of finish and buff.

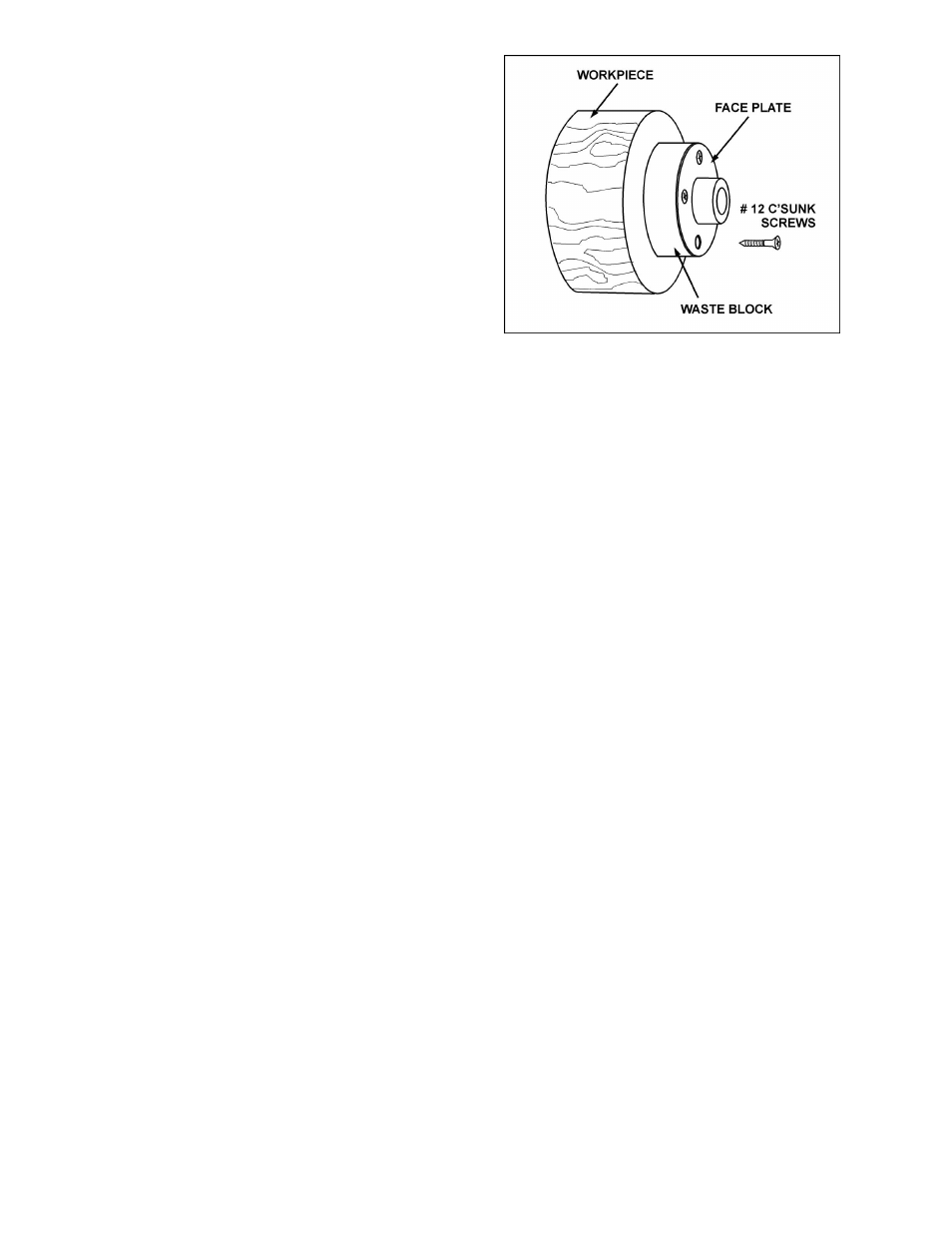

Face Plate and Bowl Turning

Face plate turning is normally done on the

inboard side of the headstock over the bed.

Larger workpieces must be turned on the

outboard side (remove tailstock and tool support

base, and move headstock to opposite end of

bed - see Figure 9).

Mounting Stock

Use of a face plate is the most common method

for holding a block of wood for turning bowls and

plates:

1. Select stock at least 1/8" to 1/4" larger than

each dimension on the finished workpiece.

2. Always select the largest diameter face plate

that can be used for the workpiece to be

turned.

3. True one surface of the workpiece for

mounting against the face plate.

4. Using the face plate as a template, mark the

location of the mounting holes on the

workpiece, and drill pilot holes of the

appropriate size. Face plates are drilled for

No. 12 screws. (Phillips and square drive

screws will hold up better than slotted

screws. Sheel metal screws are case

hardened with deeper and sharper threads

than wood screws.)

If the mounting screws on the face plate

interfere with the workpiece, a glue or waste

block can be used:

5. Make a block the same diameter as the face

plate, Figure 37. Both waste block and

workpiece should have flat surfaces for

gluing.

6. Glue the block to the workpiece. Avoid using

brown paper or newspaper between the

waste block and workpiece. It may work fine

if you are using scrapers, but a slight catch

with a bowl gouge can separate the two.

NOTE: When using a waste block, be careful

with the adhesive you select. Dry workpieces

can be bonded with ordinary white or yellow glue

but must be clamped to ensure a good bond.

Green workpieces require cyanoacrylate type

glue.

Figure 37

Faceplate or Chuck?

While faceplates are the simplest, most reliable

method of holding a block of wood for turning,

chucks can also be used. As there are dozens

of chucks to choose from, the woodturner should

first consider all the different types of turning that

will be done, and read reports or discuss with

other turners who own chucks before making a

decision.

A chuck is not a requirement, but is handy when

working on more than one piece at a time.

Rather than removing screws, you simply open

the chuck and change workpieces.

The most popular ones are four jaw scroll

chucks with a variety of jaws to accommodate

different size tenons. Most also come with a

screw chuck as well.

Wood Selection

Firewood is the cheapest, most widely available

stock to use while learning to turn bowls. Simply

waste wood for a while practicing turning

techniques. Develop skill with each tool before

attempting to make a finished piece. It is best to

start with dry wood, without worrying about

drying or distortion. Once turning becomes

comfortable, try green wood which cuts very

easily. As the turner gains experience, he or she

will find extraordinary grain and figure in the

form of burls, crotches and bark inclusions.

Checks and Cracks

Green wood will check and crack. For best

results, leave logs in as long a length as you can

handle. As the material starts to dry, surface

cracks will develop on the ends of the log. Cut

off two to three inches and you should find good,

sound wood. Also cut the log in half along the

pith to avoid having it in the finished piece. Most

checks radiate from the pith.