Grounding instructions – Powermatic 3520B User Manual

Page 12

12

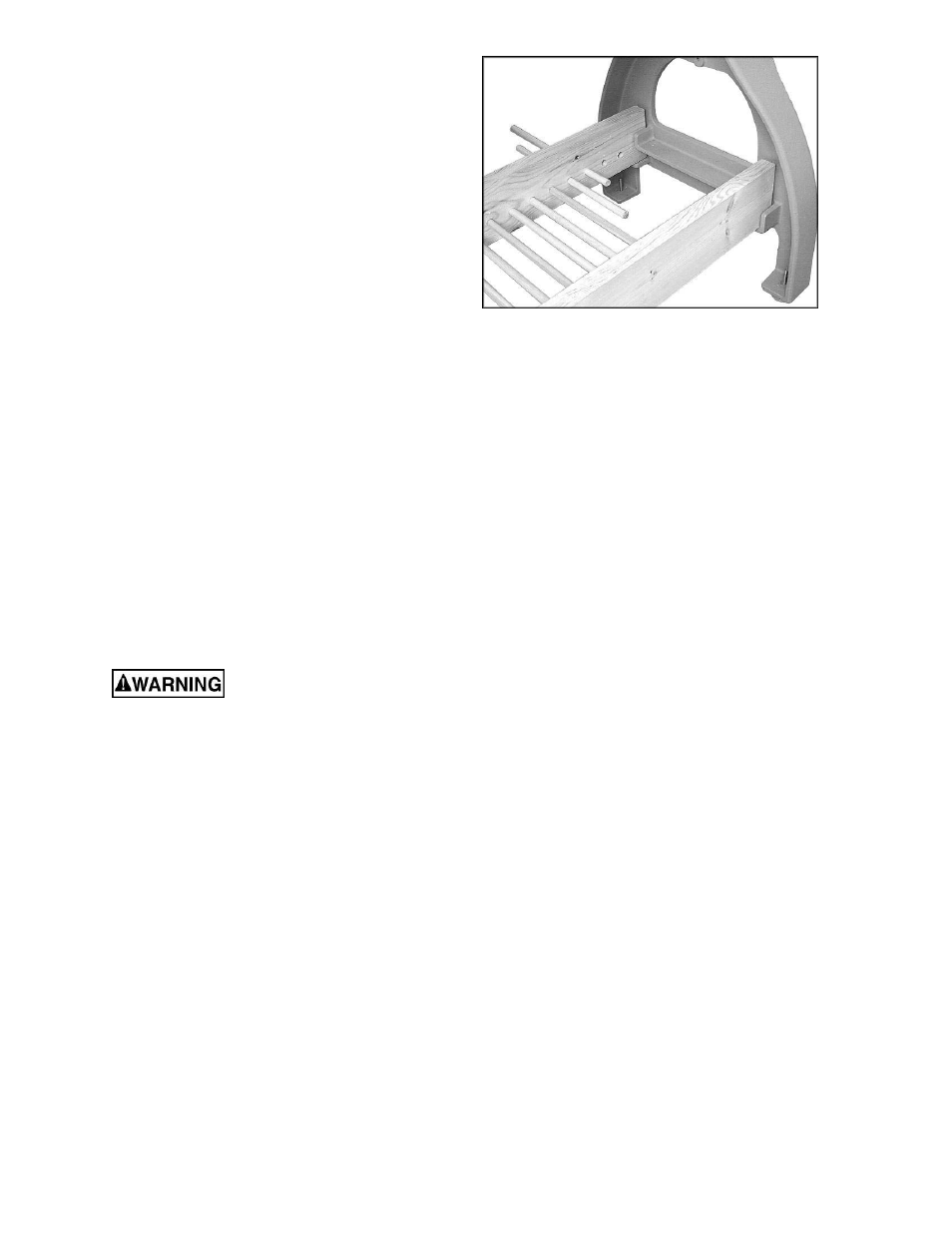

1. Mark your hole centers (2” centers) along

the length of a 2x6. Place the holes so that

the tops of the dowels will be even with the

tops of the ledges on the Lathe. Also, adjust

your hole centers as necessary so that the

first and last dowel will begin at

approximately the same distance from the

ledge at both ends of the Lathe.

2. Use a 5/8” spade bit chucked in a drill press

or in a portable drill. Bore the holes through

one 2x6; this will be the rear piece.

3. On the other 2x6, do not bore through but

only deep enough to securely hold the ends

of the dowel rods. This will be the front

piece and will provide a pleasing

appearance at the front of your Lathe.

4. When all holes have been bored, place the

2x6’s on edge in the outer ledges of the

Lathe.

5. Cut the dowel rods to length with a miter

saw or hand saw, so that after insertion the

rods will be flush with the back of the rear

2x6.

6. Insert the dowel rods through the holes in

the rear 2x6, as shown in Figure 12.

7. A strip of wood can be screwed to the rear

2x6 to cover the dowel holes and prevent

the dowels from working out.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This machine must be grounded. In the event of

a malfunction or breakdown, grounding provides

a path of least resistance for electric current to

reduce the risk of electric shock.

Improper connection of the equipment-

grounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipment-

grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Figure 12