Powermatic 3520B User Manual

Page 21

21

Inspection

Before operating the lathe, check that everything

is in proper working order:

1. Level your machine; use the adjustable

levelers to help reduce vibration.

2. Check bearings; adjust only if endplay

exists.

3. Check belt; it should be snug but not overly

tight.

4. Bed ways; keep clean, use steel wool to

remove any rust spots, and apply paste wax

to prevent buildup of rust and finishes.

5. Tool support; use a mill file to remove nicks

and dings.

6. Spindle tapers; should be clean and free of

dust and chips for proper seating of tapers.

7. Tailstock; clean and lubricate ram and

locking device.

8. Lighting; proper lighting is essential to

eliminate shadows and reduce eye strain.

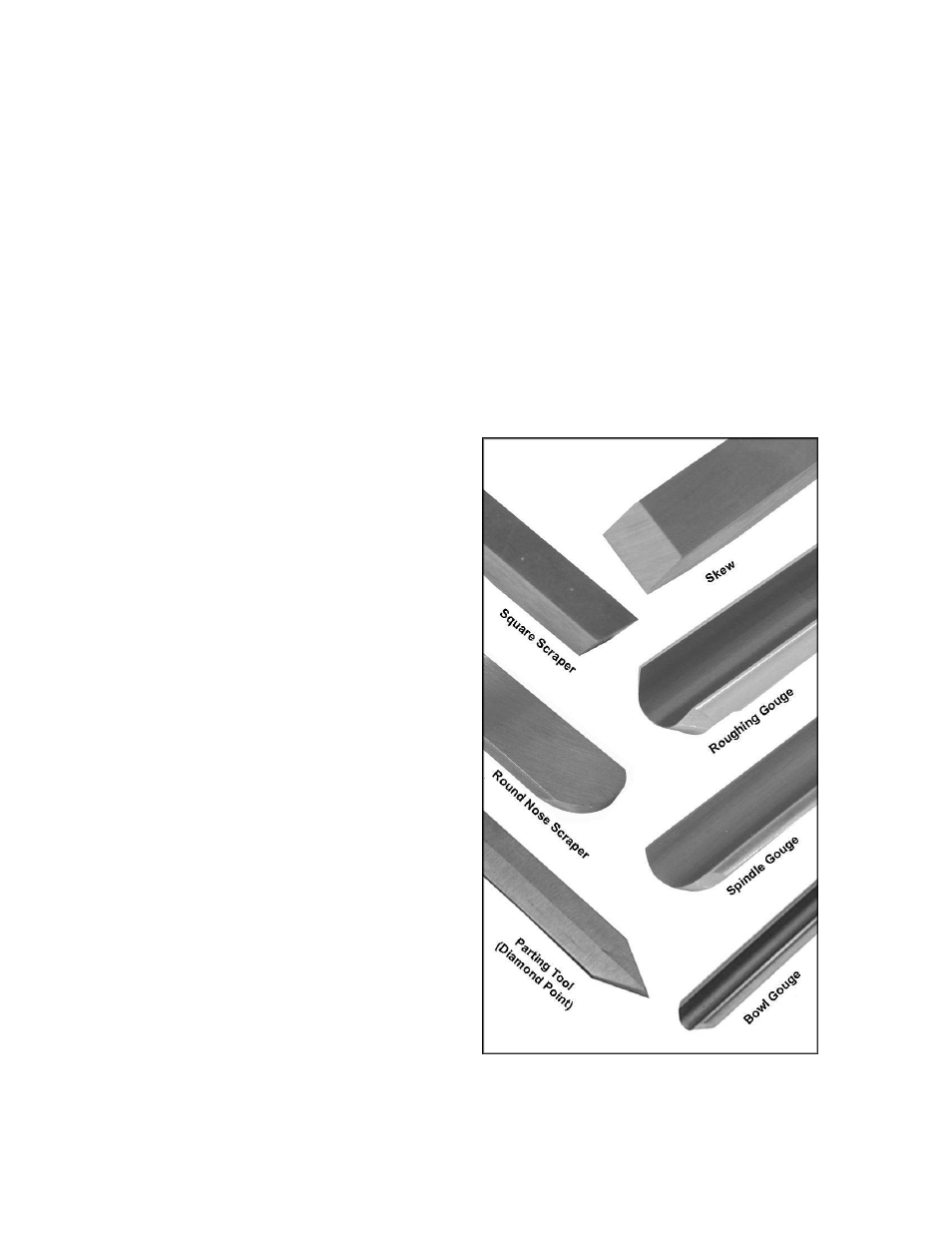

Turning Tools

If possible, select only quality, high-speed steel

turning tools. High-speed steel tools hold an

edge and last longer than ordinary carbon steel.

As one becomes proficient in turning, a variety

of specialty tools for specific applications can be

acquired. The following tools provide the basics

for most woodturning projects (see Figure 29):

Skews – 1-1/2" and 1" or 1-1/4", used to make

finishing cuts and details.

Large Roughing Gouge – 1" to 1-1/4", used to

eliminate waste wood.

Spindle Gouges – 1/4", 3/8", 1/2", used to turn

beads, coves and other details.

Deep Fluted Bowl Gouge – 1/4", 3/8" and 1/2",

used for turning bowls & plates.

Square Scraper (Bedan) – 3/8” or 1/2", used to

create square shoulders.

Large Round Nose (Domed) Scraper – 1-1/2",

used to reduce ridges on interior of bowls, round

edges of bowls, etc.

Parting Tool - 1/8", used for scraping, making a

cut-off, or to set diameters for sizing.

For safety and best performance, keep tools

sharp. If a tool stops cutting or requires

excessive pressure to make a cut, it needs to be

sharpened. A number of brand name

sharpening jigs and fixtures are available;

however, a woodturner should learn to sharpen

tools freehand.

Figure 29

Basic Turning Tools