Adjustments, Headstock and tailstock movement – Powermatic 3520B User Manual

Page 13

13

Repair or replace a damaged or worn cord

immediately.

The Lathe will operate on single phase or three

phase, 230 volt power supply. The Lathe should

be connected to a dedicated circuit. Make sure

the characteristics of your power supply match

the specifications on the motor plate of the

Lathe.

Single Phase Operation

A three wire pigtail for use on 230 volt single

phase power is attached to the inverter and may

be “hard-wired” to the power source, or

connected to a UL/CSA listed receptacle plug.

Connect the 230 volt supply to the black and

white leads and ground the green lead.

If you are hard-wiring the Lathe to a panel, make

sure a disconnect is available for the operator.

During hard-wiring of the Lathe, make sure the

fuses have been removed or the breakers have

been tripped in the circuit to which the Lathe will

be connected. Place a warning placard on the

fuse holder or circuit breaker to prevent it being

turned on while the machine is being wired.

Three Phase Operation

If three phase power is used, it will be necessary

to replace the pigtail wire attached to the

inverter with a 12/4 wire and connect the three

hot leads to the inverter at R, S, T as shown in

the wiring diagram on page 40. Always connect

the ground lead.

Extension cords

If an extension cord is necessary, make sure the

cord rating is suitable for the amperage listed on

the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

of power and overheating.

Use the chart in Figure 13 as a general guide in

choosing the correct size cord. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord.

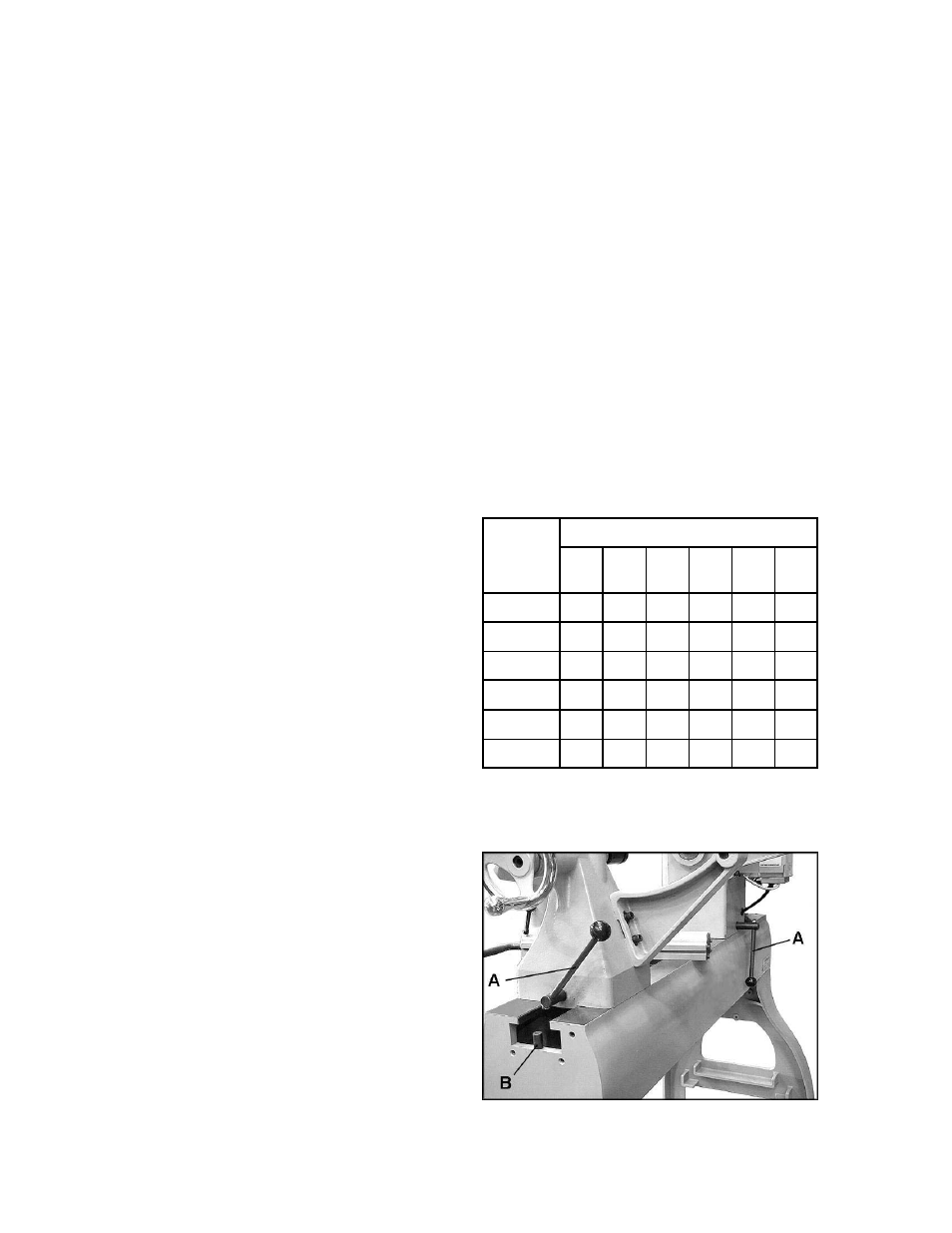

Adjustments

Headstock and Tailstock Movement

To slide the headstock or tailstock, swing the

locking handle (A, Figure 14) backward or

forward until the headstock/tailstock can slide

freely. When the headstock/tailstock is

positioned, rotate the locking handle to tighten it

securely.

Recommended Gauges (AWG) of Extension Cords

Amps

Extension Cord Length *

25

feet

50

feet

75

feet

100

feet

150

feet

200

feet

<

5 16 16 16 14 12 12

5

to

8 16 16 14 12 10 NR

8

to

12 14 14 12 10 NR NR

12

to

15 12 12 10 10 NR NR

15

to

20 10 10 10 NR NR NR

21

to

30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

Figure 13

Figure 14