Deliming solvents, Tank cleanout procedure, Ignition module system – Lochinvar Commercial Gas Glass Lined Tanke Type Water Heater CG150 User Manual

Page 23: System diagnostics

23

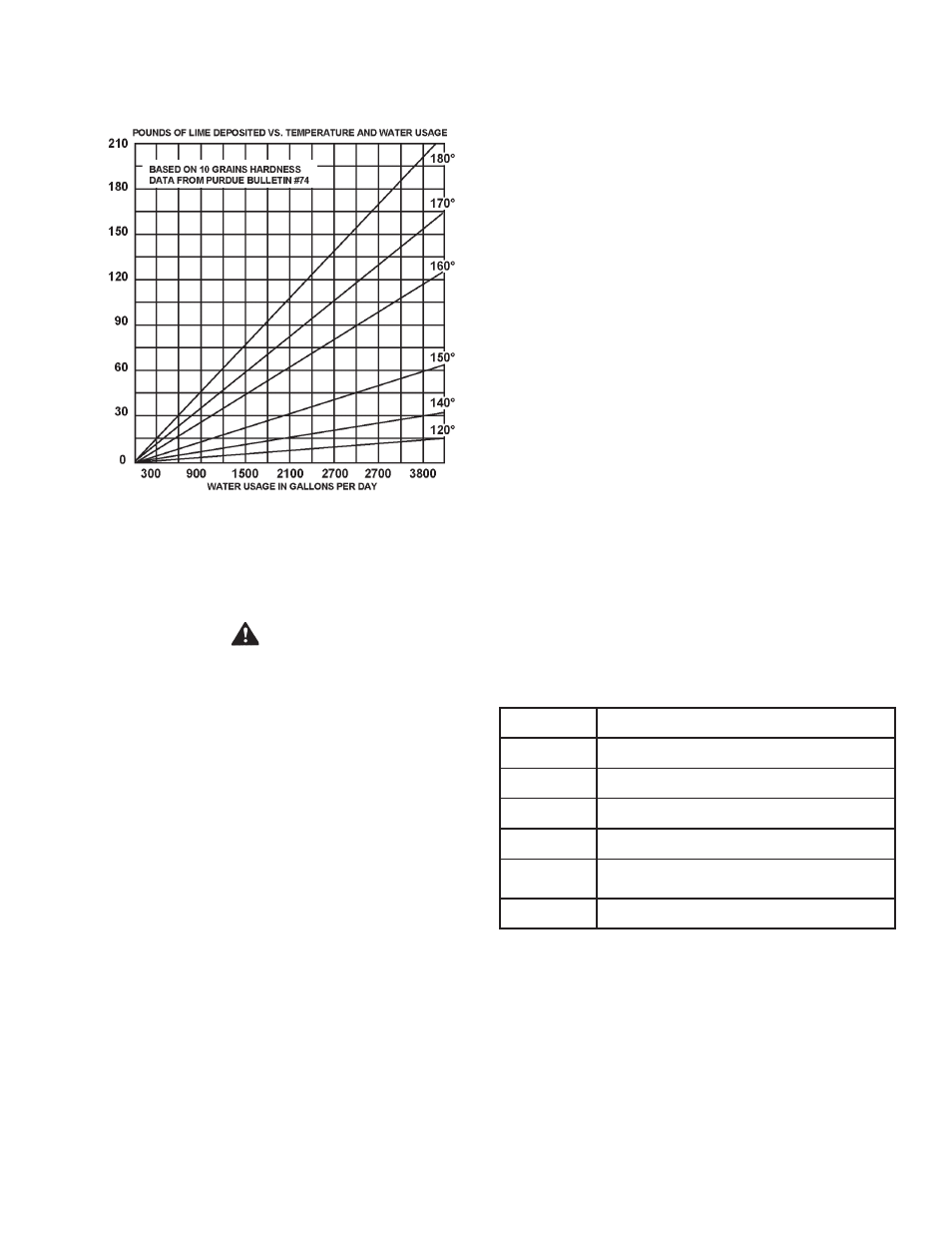

Example 2:

If initial inspection after 6 months shows 2” of lime accumulation.

Therefore, the heater should be delimed every 3 months.

FIGURE 14

DELIMING SOLVENTS

Hydrochloric base acids are not recommended for use on glass

lined tanks.

CAUTION

Observe handling instructions on label of product being used.

TANK CLEANOUT PROCEDURE

The following practices will ensure longer life and enable the unit

to operate at its designed efficiency:

1. Once a month the heater should be flushed. Open drain valve

and allow two gallons of water to drain from the heater. Inlet water

valve should remain open to maintain pressure in tank.

2. A cleanout opening is provided for periodic cleaning of the tank.

Gas must be shut off and heater drained before opening cleanout.

To clean heater through cleanout opening, proceed as follows:

1. Drain heater.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove six (6) hex head screws securing tank cleanout plate

and remove plate.

4. Remove lime, scale, or sediment using care not to damage the

glass lining.

5. Inspect cleanout plate gasket, if new gasket is required, replace

with part no. 9004099215.

6. Install cleanout plate. Be sure to draw plate up tight by

tightening screws securely.

7. Replace outer jacket cover plate.

In some water areas the sediment might not be removed by this

method and may result in the water heater making rumbling or

boiling noises.

IGNITION MODULE SYSTEM

Before calling your service agent, the following checklist should

be examined to eliminate obvious problems from those requiring

replacement or servicing.

— Check that “main manual gas shutoff valve” is fully open and

that gas service has not been interrupted.

— Check that after following the appliance OPERATING

INSTRUCTIONS, the “Top Knob” of the appliance gas valve

is in “ON” position.

— Check electrical supply to the appliance for possible blown (or

tripped) fusing or power interruption.

— Is the water temperature in tank below the thermostat dial

setting on the appliance thermostat (calling for heat)?

— It is possible that the high limit (E.C.O.) has functioned to shut

off the appliance. See FEATURES — Water Temperature

Control for reset procedure. Contact your serviceman if limit

continues to function to shut off appliance.

SYSTEM DIAGNOSTICS

Your water heater is equipped with an ignition module that

incorporates a diagnostic system to assist in troubleshooting

the appliance. The indicator codes on the ignition module are

as follows:

1 flash

System lockout (retries or cycles exceeded)

2 flashes

Pressure switch stuck close

3 flashes

Pressure switch stuck open

4 flashes

Open on high temperature limit switch (eco)

6 flashes

115 volt AC power reversed (check polarity)

7 flashes

Low flame sense signal (make sure flame

sensor is in burner flame)

8 flashes

Check ignitor

continuous flash -> continuous flame sensed > 5 seconds without

gas valve

continuous on -> internal control failure - replace ignition control

module.

Use this diagnostic system in conjunction with the “OPERATIONAL

CHECKLIST” and the “SEQUENCE OF OPERATION” to

troubleshoot the appliance.