Start-up – Lochinvar Condensing Boiler 1.5 User Manual

Page 44

44

Installation & Operation Manual

9

Start-up

Check flame and combustion

(continued)

4. Navigate to the Service Screen from the Home Screen by

pressing the MAIN MENU button and then the SERVICE

button.

5. On the Service Screen place heater into Service Mode by

selecting the START button, then selecting Set Gas Valve

1 - High.

6. Insert the probe from a combustion analyzer into the hole

left by the removal of the flue temperature sensor.

7. Once the heat exchanger has modulated up to rate,

measure the combustion. The values should be in

the range listed in Table 9A below. CO levels should

be less than 200 ppm for a properly installed unit.

If the combustion is not within range reference the

Troubleshooting Section in the Crest Service Manual for

possible causes and corrective actions.

Set space heating operation

Verify space heat circulator mode

The system pump output can be programmed to never

run (OFF), run only when a space heating demand is

present (ON), or run continuously except during warm

weather shutdown (WWSD). If the boiler is not heating

an indirect HW (Hot Water) tank, it also turns on the

boiler pump. After the space heating call for heat ends,

and the system pump is programmed as ON, the system

pump continues to run for a short period of time. If the

boiler pump was running, it continues to run for a short

period of time as well. These pump delays are factory

set to 30 seconds. If different delays are desired, the

appropriate parameters in the control must be changed.

See the Crest Service Manual for a detailed explanation

of this procedure.

Set space heating set point temperature

During normal operation, space heating set point

temperatures can be adjusted from the Set Points Menu.

Press the following buttons to navigate to the Set Points

Menu from the Home Screen:

After pressing SETUP, the Password Screen will appear.

Entering the correct password will allow access to all

Installer Level adjustable parameters. Press ENTER

without a password to access the User Level parameters.

1. To change a set point, use the arrows to highlight a

user set point parameter and press the SELECT

button.

2. The description of the selected parameter and its

current setting will appear at the bottom of the

screen.

3. To adjust the set point, press the following

buttons to change the value being displayed:

or

4. Once the set point has been adjusted to the desired

setting press the SAVE button to change the set

point.

5. Once all the necessary adjustments have been made,

press the HOME button to return to the Home

Screen.

Note: The SAVE button must be pressed to ensure proper

programming of the controls. Failure to press the SAVE

button will require all changes to be reprogrammed.

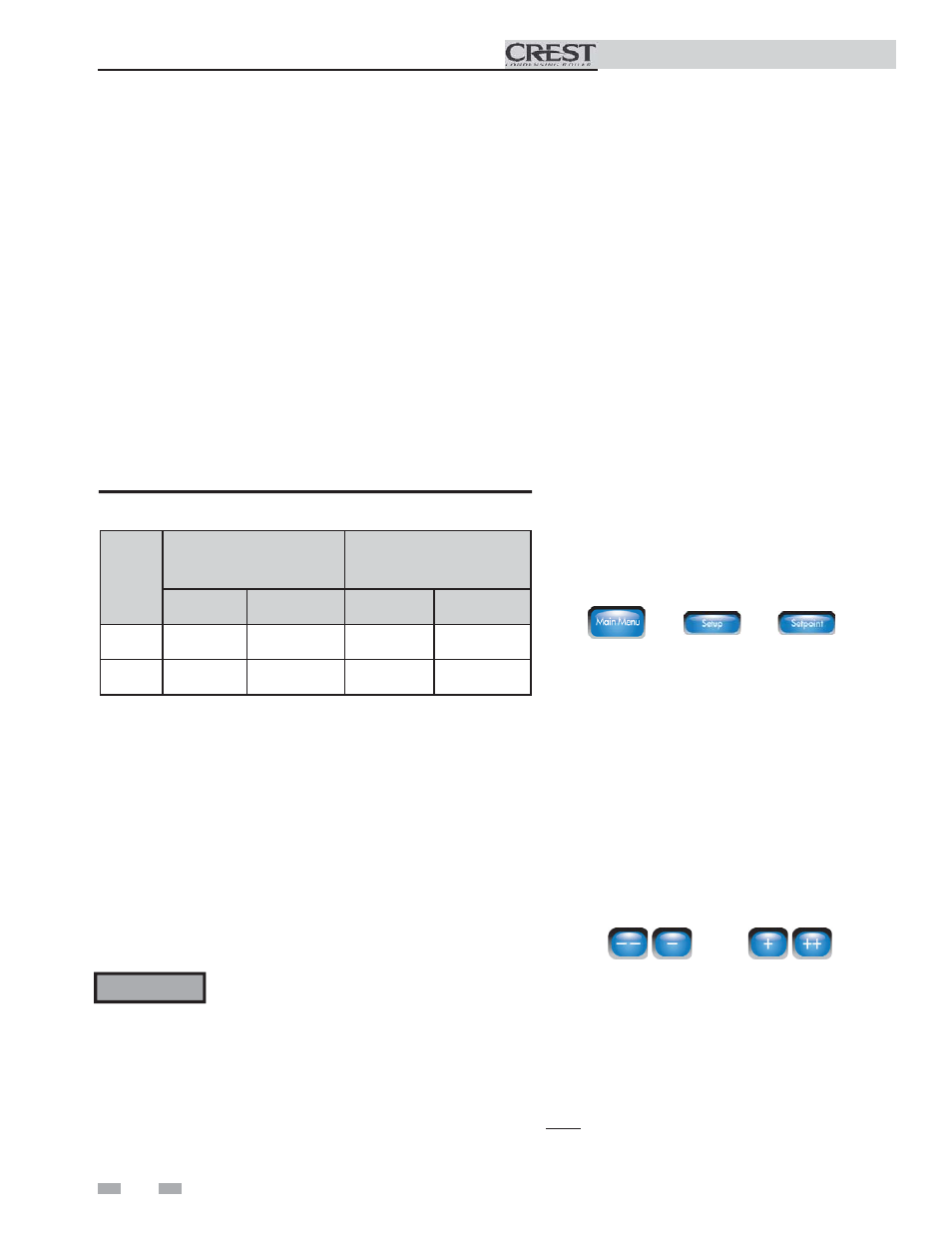

Table 9A Flue Products Chart

8. After

Gas Valve 1 is set, repeat the same procedure for the

second gas train by selecting Set Gas Valve 2 - High on

the Service Screen.

9. Once the heater analysis is complete, test the safety

shutoff device by turning the manual shutoff valve to the

OFF position and ensuring that the heater shuts down

and registers an alarm. Open the manual shutoff valve

and reset the control.

10. Turn the main power off to the boiler and replace the

flue temperature sensor into the flue pipe connection.

11. Place the boiler back into normal operation.

You must replace the flue gas temperature

sensor to prevent flue gas spillage into

the room. Failure to comply could

result in severe personal injury, death, or

substantial property damage.

ƽ WARNING

Gas

Valve

Natural Gas

Propane

CO

2

O

2

CO

2

O

2

1 - High 3.5% - 5.5% 11.2% - 14.8% 5.1% - 6.8% 10.5% - 13.2%

2 - High 7.8% - 8.6% 5.6% - 7.1% 9.4% - 11.0% 4.1% - 6.6%

>>

>>