Determine boiler location, Installation & operation manual – Lochinvar Condensing Boiler 1.5 User Manual

Page 13

Installation & Operation Manual

4. If a single combustion air opening is provided to bring

combustion air in directly from the outdoors, the

opening must be sized based on a minimum free area

of one square inch per 3000 Btu/hr (7 cm

2

per kW). This

opening must be located within 12” (30 cm) of the top of

the enclosure (see FIG. 1-7).

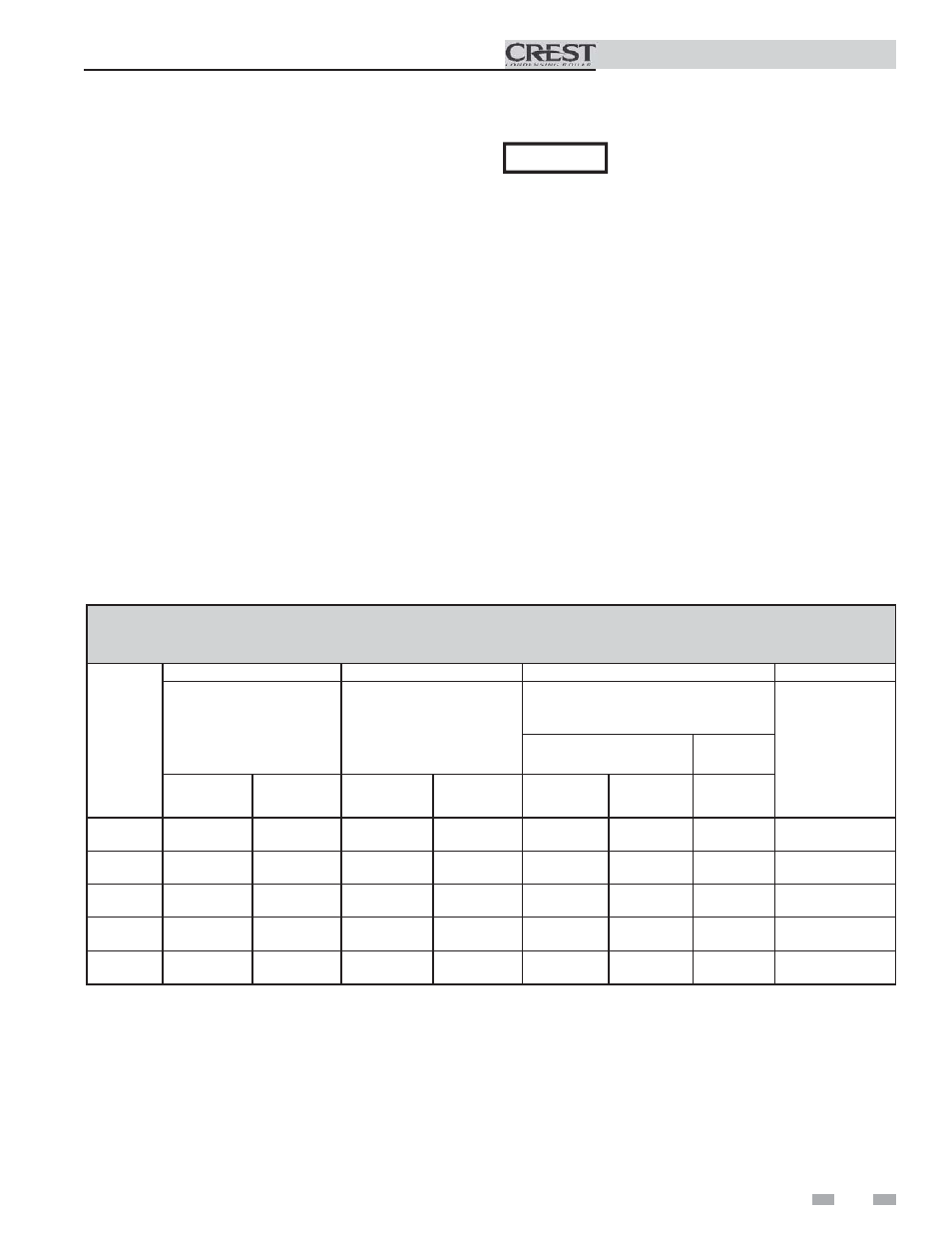

TABLE - 1B

MINIMUM RECOMMENDED COMBUSTION

AIR SUPPLY TO EQUIPMENT ROOM

Model

Number

FIG. 1-4

FIG. 1-5

FIG. 1-6

FIG. 1-7

*Outside Air from

2 Openings Directly from

Outdoors

1

*Outside Air from

2 Ducts Delivered from

Outdoors

1

Inside Air from

2 Ducts Delivered from Interior Space

2

*Outside Air from

1 Opening Directly

from Outdoors, in

2

(cm

2

)

1

Same Story

Different

Stories

Top

Opening, in

2

(cm

2

)

Bottom

Opening, in

2

(cm

2

)

Top

Opening, in

2

(cm

2

)

Bottom

Opening, in

2

(cm

2

)

Top

Opening, in

2

(cm

2

)

Bottom

Opening, in

2

(cm

2

)

Total

Opening, in

2

(cm

2

)

FB 1500

375

(2420)

375

(2420)

750

(4839)

750

(4839)

1500

(9678)

1500

(9678)

3000

(19355)

500

(3226)

FB 2000

500

(3226)

500

(3226)

1000

(6452)

1000

(6452)

2000

(12904)

2000

(12904)

4000

(25807)

667

(4304)

FB 2500

625

(4033)

625

(4033)

1250

(8065)

1250

(8065)

2500

(16129)

2500

(16129)

5000

(32258)

833

(5381)

FB 3000

750

(4839)

750

(4839)

1500

(9678)

1500

(9678)

3000

(19355)

3000

(19355)

6000

(38710)

1000

(6452)

FB 3500

875

(5646)

875

(5646)

1750

(11291)

1750

(11291)

3500

(22581)

3500

(22581)

7000

(45162)

1167

(7530)

All dimensions based on net free area in square inches. Metal

louvers or screens reduce the free area of a combustion air

opening a minimum of approximately 25%. Check with

louver manufacturers for exact net free area of louvers.

ƽ CAUTION

Under no circumstances should the

equipment room ever be under negative

pressure. Particular care should be taken

where exhaust fans, attic fans, clothes dryers,

compressors, air handling units, etc., may

take away air from the unit.

The result is improper combustion and a non-warrantable,

premature appliance failure.

EXHAUST FANS: Any fan or equipment which exhausts air

from the equipment room may deplete the combustion air

supply and/or cause a downdraft in the venting system. Spillage

of flue products from the venting system into an occupied

living space can cause a very hazardous condition that must be

corrected immediately.

The combustion air supply must be completely free of any

flammable vapors that may ignite or chemical fumes which may

be corrosive to the appliance. Common corrosive chemical

fumes which must be avoided are fluorocarbons and other

halogenated compounds, most commonly present as refrigerants

or solvents, such as Freon, trichlorethylene, perchlorethylene,

chlorine, etc. These chemicals, when burned, form acids which

quickly attack the stainless steel heat exchanger, headers, flue

collectors, and the vent system.

Combustion air requirements are based on the latest edition

of the National Fuel Gas Code, NFPA 54 / ANSI Z223.1; in

Canada refer to the latest edition of CGA Standard CAN/CSA

B149.1. Check all local code requirements for combustion air.

1

Determine boiler location

(continued)

The above requirements are for the appliance only; additional gas fired appliances in the equipment room will require an increase

in the net free area and/or volume to supply adequate combustion air for all appliances.

No combustion air openings are needed when the appliance is installed in a space with a volume NO LESS than 50 cubic feet per

1,000 Btu/hr of all installed gas fired appliances. Buildings MUST NOT be of *“Tight Construction”

3

.

1

Outside air openings shall directly communicate with the outdoors.

2

Combined interior space must be 50 cubic feet per 1,000 Btu/hr input. Buildings MUST NOT be of *“Tight Construction”.

3

”Tight Construction” is defined as a building with less than 0.40 ACH (air changes per hour). For buildings of “Tight

Construction”, provide air openings into the building from outside.

Where two openings are provided, one must be within 12"

(30 cm) of the ceiling and one must be within 12" (30 cm) of

the floor of the equipment room. Each opening must have a

net free area as specified in Table 1B. Single openings shall

commence within 12" (30 cm) of the ceiling. The minimum

dimension of air openings shall not be less than 3" (80 mm).

13