Maintenance, Inspect ignition and flame sense electrodes, Check ignition ground wiring – Lochinvar Condensing Boiler 1.5 User Manual

Page 56: Check all boiler wiring, Check control settings, Perform start-up and checks, Check burner flame, Check flame signal

56

Installation & Operation Manual

11

Maintenance

Inspect ignition and flame

sense electrodes

1. Remove the ignition and both flame sense electrodes

from the burner plate.

2. Remove any deposits accumulated on the ignition/

flame sense electrodes using sandpaper. If the

electrodes cannot be cleaned satisfactorily, replace

with new ones.

3. Replace ignition/flame sense electrodes, making

sure the gaskets are in good condition and correctly

positioned.

Check ignition ground wiring

1. Inspect boiler ground wire from the heat exchanger

access cover to ground terminal strip.

2. Verify all wiring is in good condition and securely

attached.

3. Check ground continuity of wiring using continuity

meter.

4. Replace ground wires if ground continuity is not

satisfactory.

Check all boiler wiring

1. Inspect all boiler wiring, making sure wires are in

good condition and securely attached.

Check control settings

1. Navigate to the Setup Screen and check all settings.

See Section 1 of the Crest Service Manual. Adjust

settings if necessary. See Section 1 of the Crest

Service Manual for adjustment procedures.

2. Check settings of external limit controls (if any) and

adjust if necessary.

Perform start-up and checks

1. Start boiler and perform checks and tests specified

in Section 9 - Start-up.

2. Verify cold fill pressure is correct and that operating

pressure does not go too high.

Check burner flame

1. Inspect flame through observation windows.

2. If the flame is unsatisfactory at either high fire

or low fire, remove and clean the burner. Clean

the burner thoroughly using a vacuum cleaner

or compressed air. Do not use compressed air to

clean the burner if cleaning is performed inside a

building.

• Shut down the boiler:

- Follow the “To Turn Off Gas to Appliance” instructions

for the boiler in Section 9 - Startup.

- Do not drain the boiler unless it will be exposed to

freezing temperatures. If using freeze prevention fluid

in system, do not drain.

3. Allow time for the boiler to cool to room temperature if it has

been firing.

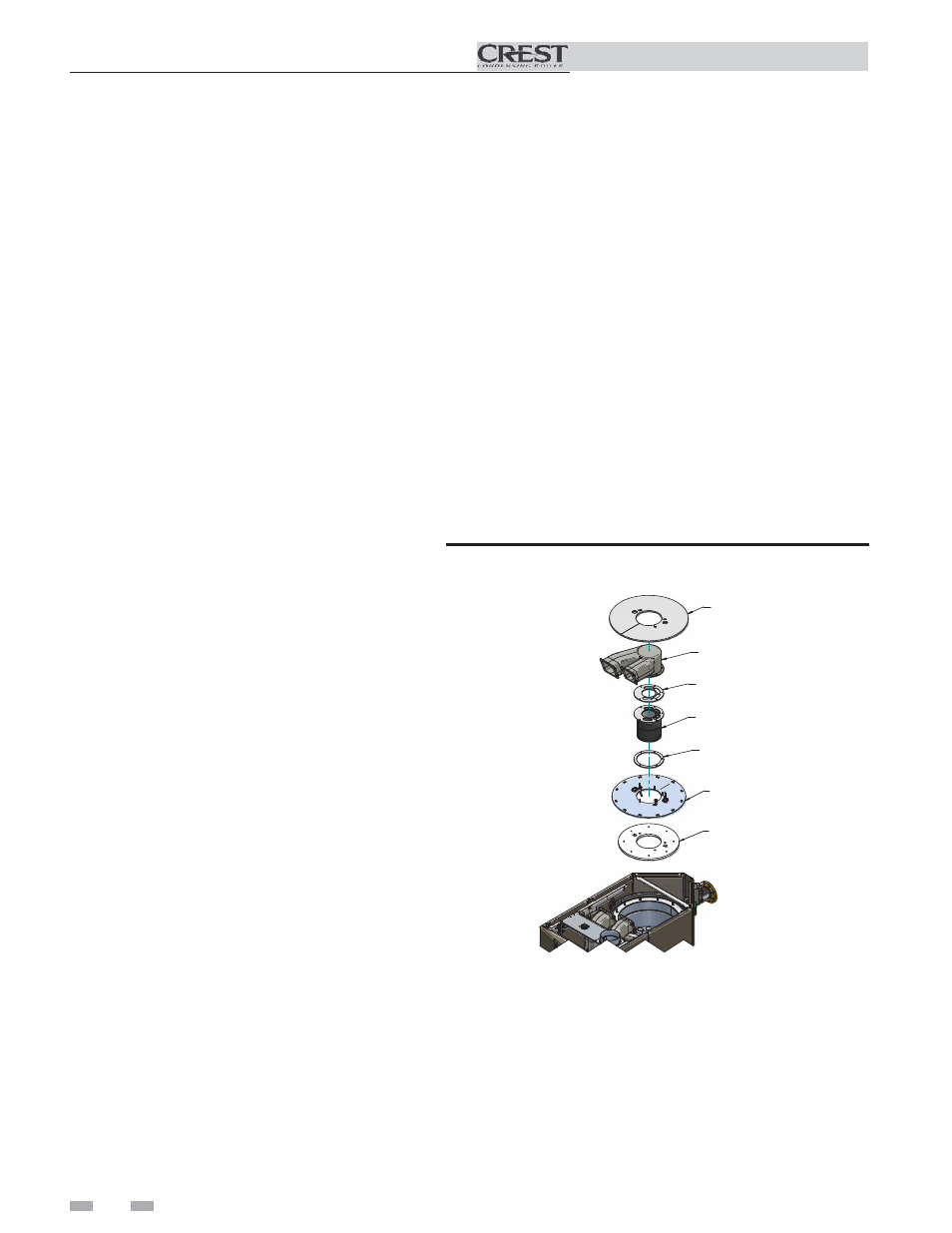

4. Remove the top access panel to remove the gas/air manifold

assembly.

5. Remove the nuts securing the burner to the burner mounting

plate. Remove the burner (FIG. 11-2).

6. When replacing the burner, ensure gaskets are in good condition

and positioned correctly (FIG. 11-2).

7. When securing the burner, be sure to tighten the nuts, but DO

NOT over-tighten. Tighten the nuts to a torque setting of no

more than 6.2 ft.-lbs. When securing the burner mounting plate

be sure to tighten the nuts, but DO NOT over-tighten. Tighten

the nuts to a torque setting of no more than 15.5 ft.-lbs.

BURNER

ASSEMBLY

MANIFOLD

GASKET

AIR/GAS

MANIFOLD

INSULATION

BURNER

GASKET

BURNER PLATE

FIBERBOARD

Figure 11-2 Burner Assembly

Check flame signal

1. At high fire of each combustion system, the flame signal shown

on the display should be at least 10 microamps.

2. A lower flame signal may indicate a fouled or damaged flame

sense electrode. If cleaning the flame sense electrodes does

not improve, ground wiring is in good condition, and ground

continuity is satisfactory, replace the flame sense electrode.

3. See Section 3 - Troubleshooting in the Crest Service Manual for

other procedures to deal with low flame signal.