Operation, The welding circuit – Lincoln Electric POWER-ARC 4000 SVM103-A User Manual

Page 26

Return to Master TOC

Return to Master TOC

POWER-ARC 4000

B-11

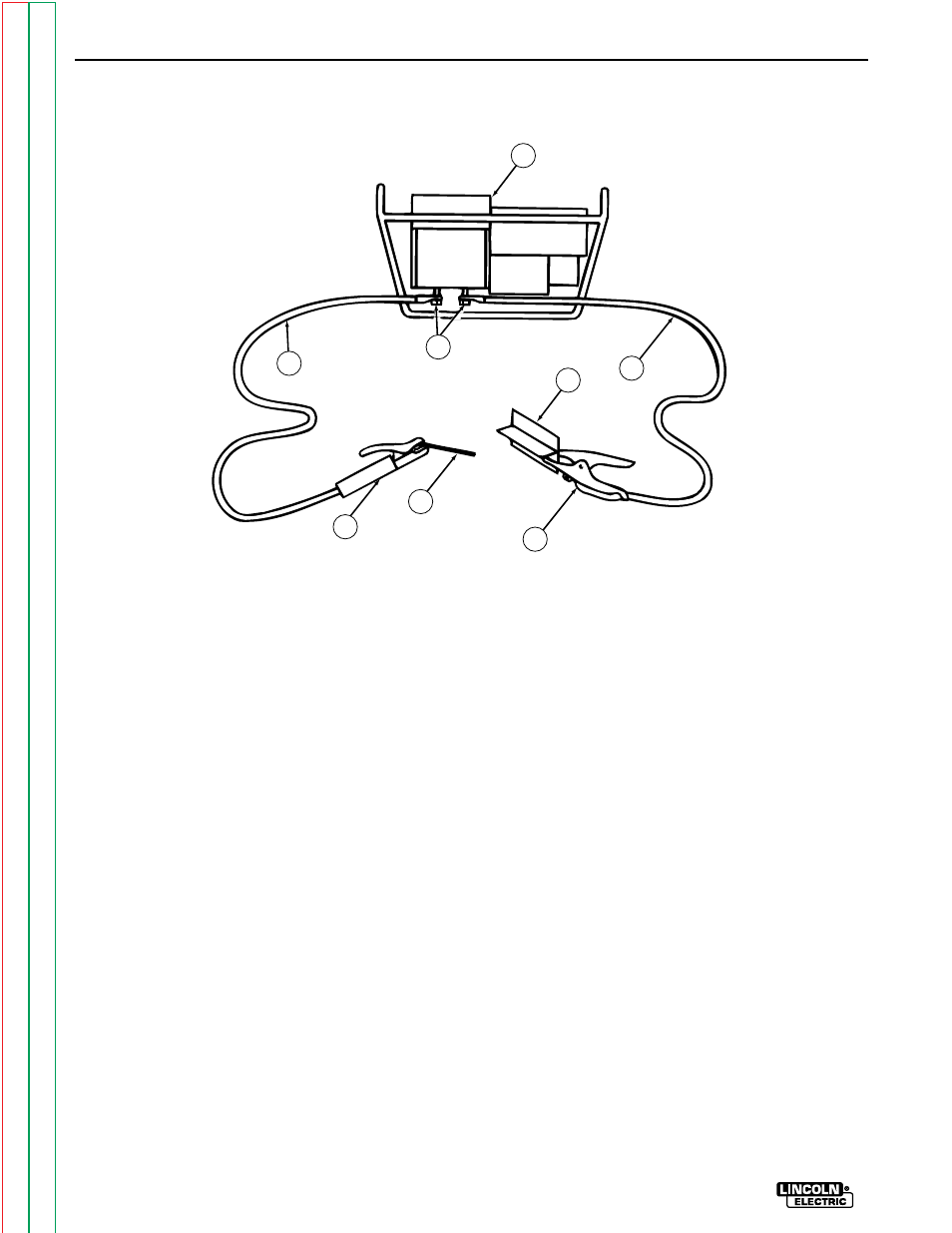

THE WELDING CIRCUIT

When everything is connected properly, the current

from the power source causes the electrode to melt

and bond the metal being welded. Figure B.3. shows

the components of the basic welding circuit. The cir-

cuit starts at the electrode cable connection and ends

at the work cable connection. Current flows from the

POWER-ARC 4000 through the electrode cable, the

electrode holder, the electrode, and across the arc.

On the work side of the arc, current flows through the

work to the work clamp, the work cable, and back to

the machine. The circuit must be complete for current

to flow. That means the work clamp must be tightly

connected to clean base metal. You should remove

any paint or rust as necessary to get a good connec-

tion. Also, you need to connect the work clamp as

close as possible to the area you want to weld. Avoid

letting the welding circuit pass through hinges, bear-

ings, electronic components or similar devices that

can be damaged by high current.

THE ARC

The electric arc is made between the work and the tip

of the electrode. You make a gap for the arc in the

welding circuit by holding the electrode tip 1/16 to 1/8

inch (1.6 to 3.2 mm) away from the work. You must

establish the arc and hold it as you move the arc along

the joint you’re welding. The arc melts both the elec-

trode and the base metal of the work as you move.

Figure B.4. shows what’s happening in the welding

arc. The arc itself is the electric current flowing

between the tip of the electrode and the work. Its

temperature is about 6000°F (3316°C). The arc is very

bright and cannot be looked at with the naked eye

without risk of painful and perhaps permanent injury.

A very dark lens specifically designed for arc welding

must be used with the handshield or headshield when-

ever viewing the arc.

The arc melts the base metal and actually digs into it.

The molten metal forms a pool or crater and tends to

flow away from the arc. As it moves away, it cools and

solidifies. Slag forms on the top of the weld and pro-

tects it as it cools.

OPERATION

5

3

4

7

6

8

2

1

FIGURE B.3 – WELDING CIRCUIT CONNECTIONS

1. POWER SOURCE

2. ELECTRODE CABLE

3. ELECTRODE HOLDER

4. ELECTRODE

5. OUTPUT TERMINALS

6. WORK

7. WORK CLAMP

8. WORK CABLE