Rods. table b.4, welding applications, gives you, On welding techniques, see welding guide- lines, Operation – Lincoln Electric POWER-ARC 4000 SVM103-A User Manual

Page 25: Welding guidelines, Stick welding

POWER-ARC 4000

B-10

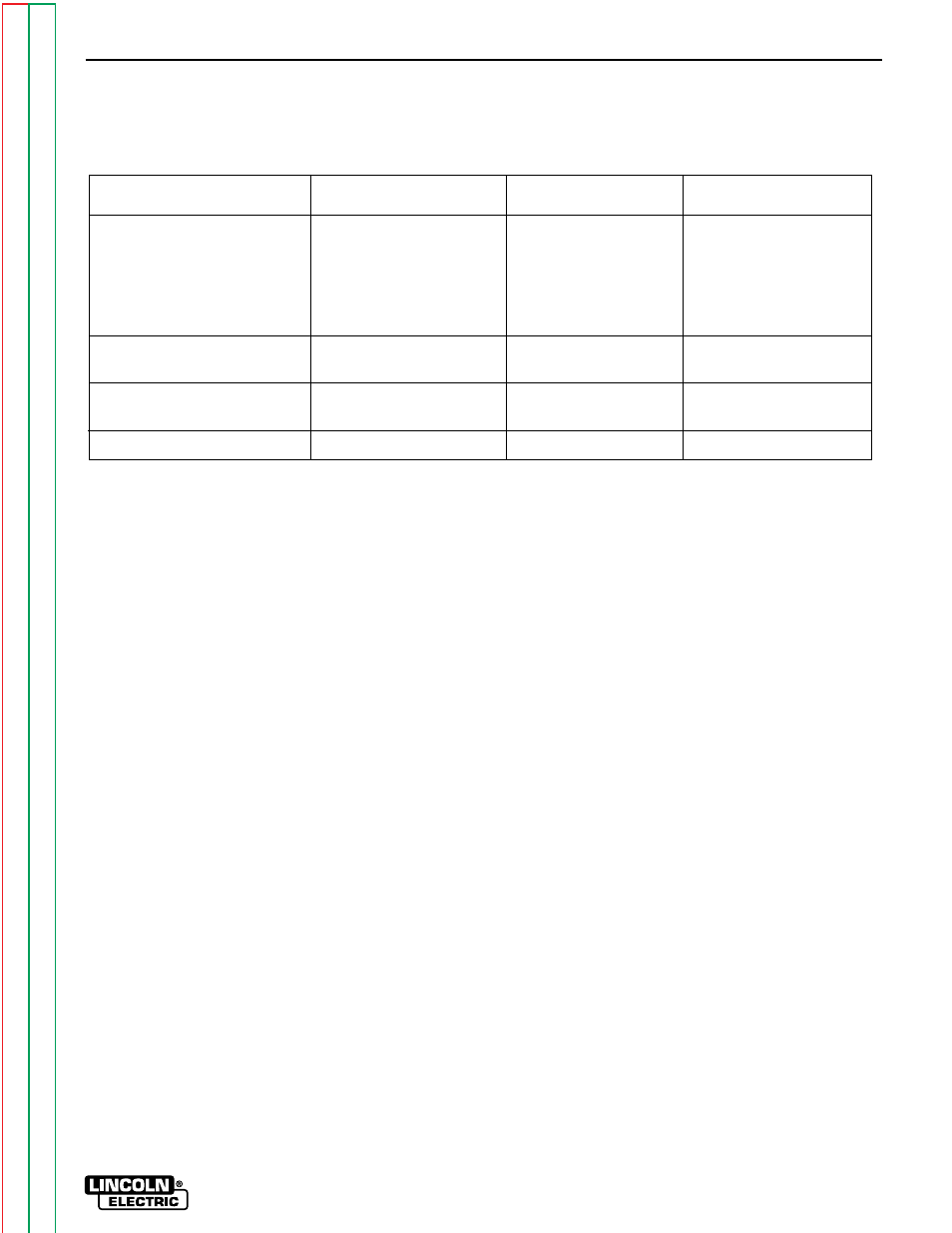

TABLE B.4

WELDING APPLICATIONS/ELECTRODE SELECTION GUIDE

Material Thickness

Electrode Type

Size

Setting

1/8” and thinner

FLEETWELD

®

37

3/32”

90 amps

1

AWS E6013

FLEETWELD

®

180

70 amps

AWS E6011

STABLE ARC

™

7018

90 amps

AWS E7018

3/16” Maximum

FLEETWELD

®

37

1/8”

125 amps

AWS E6013

5/16” Maximum

FLEETWELD

®

180

1/8”

90 amps

AWS E6011

Any Thickness

WEARSHIELD

®

1/8”

100 amps

NOTES:

The values listed are suggested settings. Actual setting may vary depending on individual preference and/or spe-

cific application. Beginners should use STABLE ARC E7018.

For electrodes not listed, follow tables that are packed with the electrodes.

Ask for the Lincoln WELD DIRECTORY (Publication M210) for a complete listing of all Lincoln stick electrodes

available.

1

AWS = American Welding Society

OPERATION

NOTE: The serviceability of a product or structure

utilizing this type of information is and must

be the sole responsibility of the builder/user.

Many variables beyond the control of The

Lincoln Electric Company affect the results

obtained in applying this type of informa-

tion. These variables include, but are not

limited to, welding procedure, plate chem-

istry and temperature, weldment design,

fabrication methods and service require-

ments.

STICK WELDING

Stick welding is probably the most familiar welding

process known. A coated ELECTRODE, the welding

rod, is clamped into an ELECTRODE HOLDER, an

insulated clamping device, which is connected to

the ELECTRODE CABLE, a heavy wire. The WORK,

the piece of metal to be welded, is connected to the

WORK CABLE, a heavy wire with a WORK CLAMP

on one end. The two cables connect to OUTPUT

TERMINALS on the welder, which is a high current

power source. See Figure B.3.

WELDING GUIDELINES