Operation – Lincoln Electric INVERTEC IM958 User Manual

Page 26

B-11

OPERATION

B-11

TIPS FOR IMPROVED TIG STARTING

1. Start Current:

For the best AC or DC TIG starting characteristics it

may be necessary to adjust the start current on the

front panel depending on the tungsten size. In gener-

al, larger tungsten requires more energy to establish

an arc than smaller tungsten. As an initial guideline,

set the start current according to the following recom-

mendations:

Tungsten Size (in.)

Start Current (Amps)

0.020, 0.040 1/16th

6-10 Amps

3/32 th

10-12 Amps

1/8th

12-15 Amps

2. DC Strike Current:

Aside from start current, DC strike current can also be

adjusted from the set-up menu to get a hotter or softer

start when DC TIG welding. Strike current is an initial

spike of current that lasts a few milliseconds before

the machine goes to start current. In general, the fac-

tory default of 15 amps works for most applications. If

welding on very thin materials with small diameter

tungsten, strike current can be turned down to mini-

mize burning through the weld material. Like-wise for

larger diameter tungsten strike current can be turned

up to put more energy in the tungsten.

3. AC TIG Start Power:

For AC TIG welding AC start power can be adjusted

from the set-up menu to aid starting if required. The

V310-T AC/DC when set to AC TIG will try to initiate

the arc with positive polarity until the arc is estab-

lished. Positive polarity puts more energy into heating

the tungsten but the drawback is that is can cause the

tungsten to ball excessively or to super heat. Note

super heating of the tungsten can be noticed if the

tungsten is glowing red or orange during starting. Start

Power can be adjusted within two ranges:

Range

Mode

0.5 to 1

Manual Setting

1.2 to 5.0

Incremental setting

If start power is set within the incremental range

mode, the machine tries to start electrode positive at a

relative setting of 1. If the arc fails to establish it will

repeat the start sequence each time by incrementing

the amount of electrode positive energy by 10% (0.1)

up to the start power limit setting or until the arc estab-

lishes. For comparison a start power limit of 2 if

reached will have twice the energy of the starting point

of 1. If the tungsten has too much of a ball on it or

appears to be super heating during starts the start

power limit can be turned down. In the manual setting

range, the start power will not keep incrementing up to

a limit. Instead the start power stays at whatever level

is set. For example a setting of 0.5 will start the

machine with half the normal starting energy of 1.

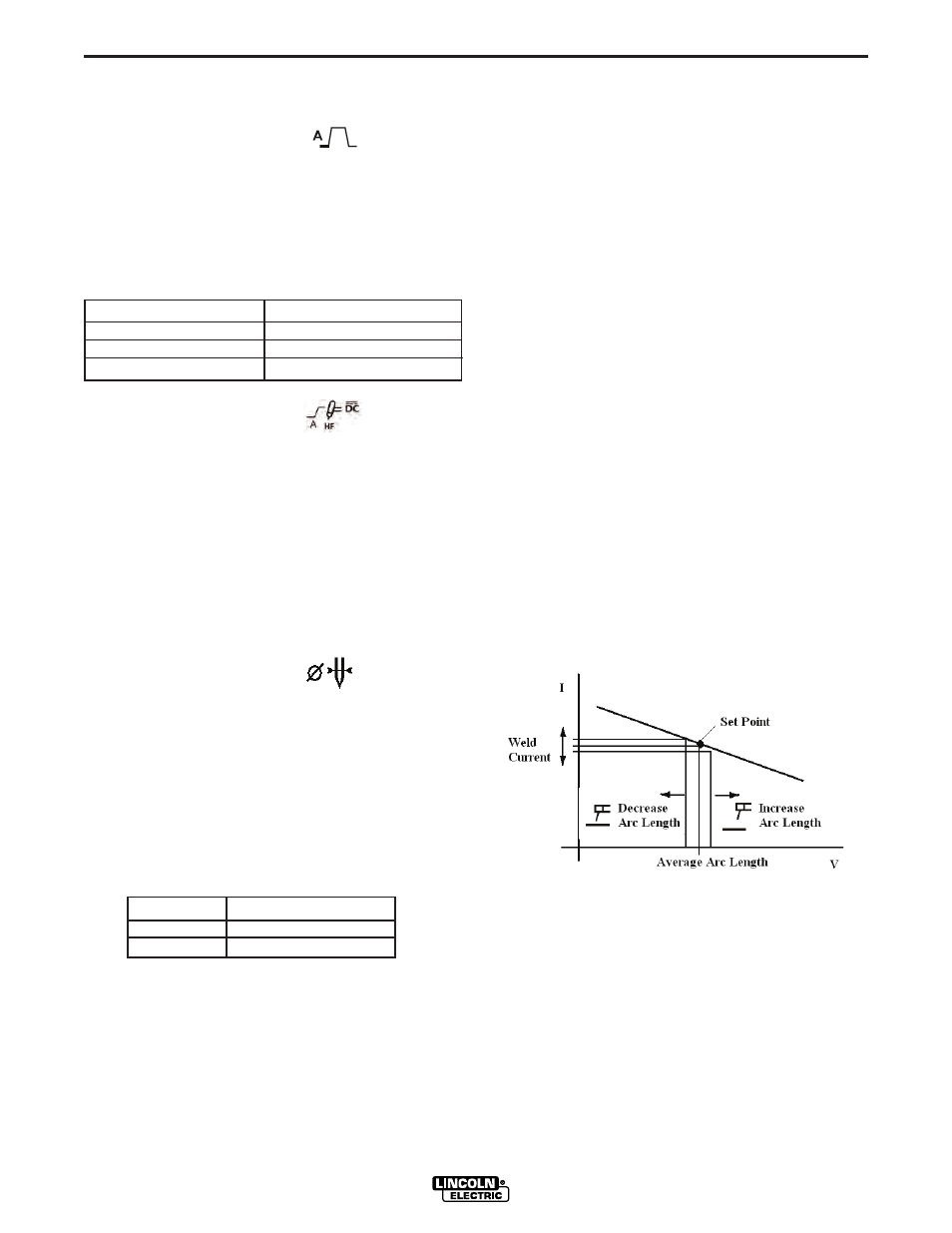

STICK CRISP MODE DYNAMIC CURRENT

REGULATION

When running E6010 electrodes DC Crisp mode is

recommended. The V310-T AC/DC has a special

dynamic current regulation that is ideal for the whip-

ping technique common to E6010 electrodes.The

machine regulates the welding current based on

changes in arc length. As the arc length is increased

and the arc voltage increases, the machine will reduce

its welding current below the set point. As the arc

length is decreased and the arc voltage decreases the

machine will increase its current.

FIGURE B.8

Arc Force Control – Arc Force is a setting that helps

reduce sticking the electrode into the weld puddle.

Increasing the arc force percentage will provide a

higher boost of current when the electrode is about to

short into the weld puddle. In Stick Crisp mode since

the current is dynamically regulated based on the arc

voltage, shorting the electrode to the work will be rare

- therefore, adjustments to the arc force percentage

will not be as noticeable in Stick Crisp mode com-

pared to Stick Soft mode.

V310-T AC/DC TIG