Hydronic piping – Lochinvar 81 - 286 User Manual

Page 35

35

Installation & Operation Manual

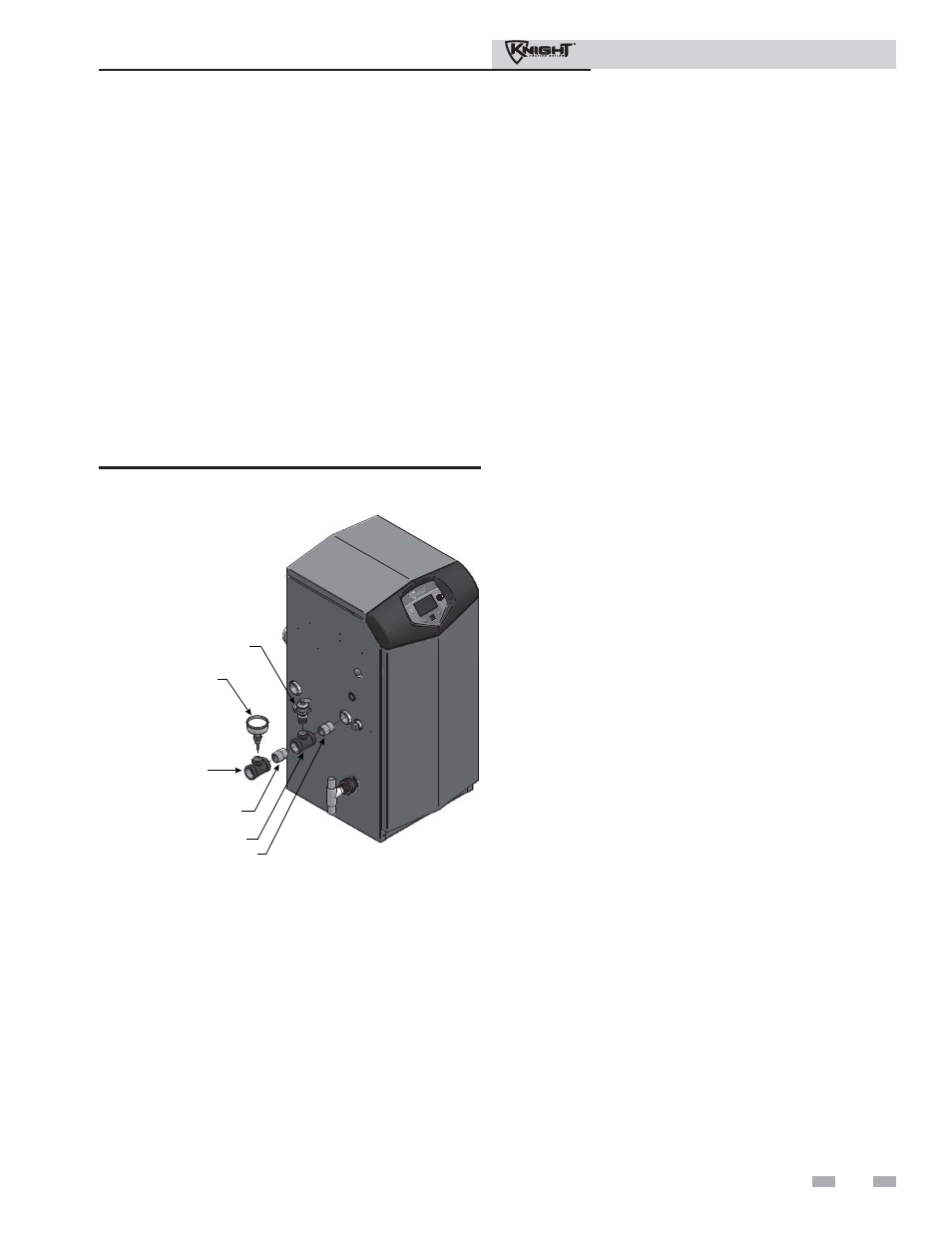

Relief valve and temperature and

pressure gauge installation

Basic steps are listed below to guide you through the

installation of the relief valve and the temperature and

pressure (T & P) gauge provided with the unit.

1. Install the tee with the 3/4 inch fitting positioned

vertically and on the top as shown in FIG. 6-1.

2. Install the relief valve into the 3/4 inch fitting of the tee

installed in Step 1 (FIG. 6-1).

3. Install a field provided close nipple and tee with the

fitting positioned vertically on the top on the

downstream side of the relief valve (see FIG. 6-1).

4. Install the temperature and pressure gauge provided with

the unit into the top fitting of the tee (a bushing may be

necessary) installed in Step 3 (FIG. 6-1).

6

Hydronic piping

(continued)

TEMPERATURE &

PRESSURE GAUGE

TEE W/FITTING ON TOP

(FIELD PROVIDED)

CLOSE NIPPLE

(FIELD PROVIDED)

TEE WITH 3/4” FITTING ON TOP

CLOSE NIPPLE

RELIEF VALVE

Figure 6-1 Relief Valve / T & P Installation

Near boiler piping components

1. Boiler system piping:

Boiler system piping MUST be sized per the pipe

requirements listed in Table 6A. Reducing the pipe size

can restrict the flow rate through the boiler, causing

inadvertent high limit shutdowns and poor system

performance. Flow rates are based on 20 feet of piping,

4 - 90° elbows, and 2 - fully ported ball valves.

2. Boiler system pump:

A Grundfos UPS26-99F pump will be provided by the

factory (for standard altitude models) as the boiler

circulation pump based on 20 feet of piping, 4 - 90°

elbows, and 2 - fully ported ball valves.

Knight boilers are capable of controlling a variable

speed boiler circulator. Variable speed circulators

MUST be sized to meet the specified minimum flow

requirements listed in FIG. 6-3 on page 37 at full

speed.

3. Domestic hot water circulating pump:

Field supplied. The pump MUST be sized to meet

the specified minimum flow requirements listed in

FIG. 6-3. Consult the indirect water heater operating

guide to determine flow characteristics for the selected

product

used.

4. Boiler

isolation

valves:

Field supplied. Full port ball valves are required.

Failure to use full port ball valves could result in a

restricted flow rate through the boiler.

5. Check

valves:

Field supplied. Check valves are recommended for

installation as shown in FIG.’s 6-4 thru 6-10. Failure to

install check valves could result in a reverse flow

condition during pump(s) off cycle.

6. Domestic indirect hot water isolation valves:

Field supplied. Full port ball valves are required. Failure

to use full port ball valves could result in a restricted flow

rate through the boiler.

7. Anti-scald mixing valve:

Field supplied. An anti-scald mixing valve is

recommended when storing domestic hot water above

115°F.

8. Unions:

Field supplied. Recommended for unit serviceability.

9. Temperature and pressure gauge:

Factory supplied. The temperature and pressure gauge is

shipped loose. It is the responsibility of the contractor to

install the temperature and pressure gauge on the boiler

water

outlet.

10. Pressure relief valve:

Factory supplied. The pressure relief valve is sized to

ASME

specifications.

11. Boiler purge valve:

Field supplied. The boiler purge valve is used to

remove entrapped air from the heat exchanger during

start-up.

12. System temperature sensor:

Lochinvar supplies a system temperature sensor.

The sensor is to be installed in the heating loop

downstream from the boiler hot water piping and

heating loop junction. Typically the sensor will be

located far enough downstream to sense system diluted

water

temperature.