Diagrams, Idealarc® dc-1000 – Lincoln Electric IDEALARC IM420-D User Manual

Page 26

F-3

DIAGRAMS

F-3

IDEALARC® DC-1000

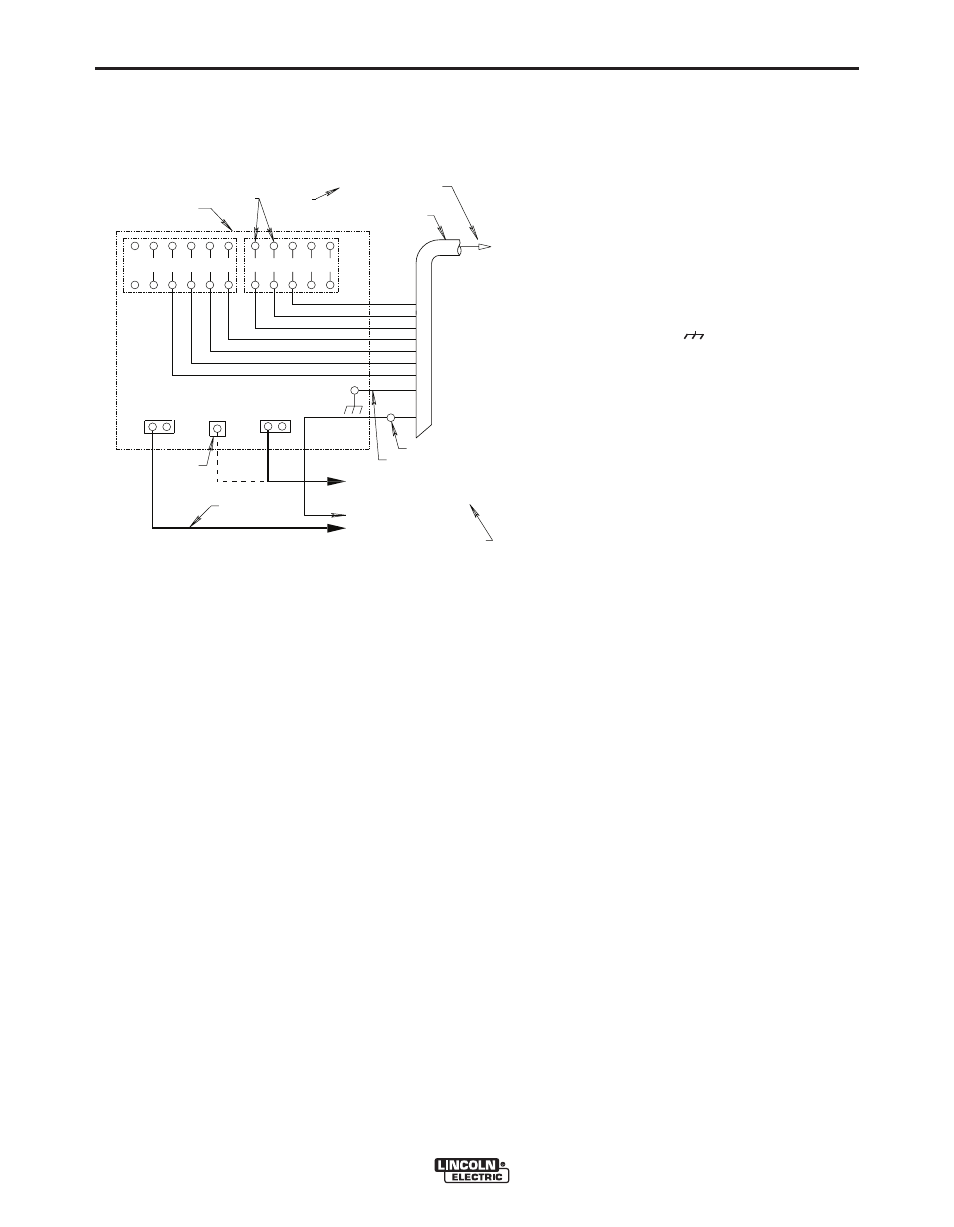

CONNECTION OF DC-1000 to NA-5

N.A.

Welding cables must be of proper capacity for the cur-

rent and duty cycle of immediate and future applica-

tions.

N.B.

Extend lead 21 using #14 or larger insulated wire phys-

ically suitable for the installation. An S16586-[ ] remote

voltage sensing work lead is available for this purpose.

Connect it directly to the work piece keeping it separate

from the welding work cable connection to work piece.

For convenience, this extended #21 lead should be

taped along the welding work cable.

N.C. Tape up bolted connection.

N.D. Connect the NA-5 control cable ground lead to the

frame terminal marked near the power source ter-

minal strip. The power source must be properly ground-

ed.

N.E.

If using an older automatic control cable with leads 75,

76, 77: Connect lead 75 to #75 on terminal strip, con-

nect lead #76 to #74 on terminal strip, connect lead

#77 to #73 on terminal strip.

N.F.

Connect the jumpers on the NA-5 voltage board as fol-

lows: Connect RED jumper to pin “S”, Connect WHITE

jumper to pin “B”.

N.G. Set the DC-1000 or DC-1500 controls as follows: Set

the control switch to “Output Control Remote”. For

Submerged Arc Processes set the switch to “C.V.

Submerged Arc”. For Open Arc Processes, set the

mode switch to “C.V. Innershield”.

N.H. For proper operation, the electrode cable

must be

snugged under the clamp bar on the left side of the NA-

5 control box.

N.J.

Terminals #73 and #74 were not present on DC-1500

machines below code 8294. These earlier code

machines are not suitable for use with the NA-5.

N.K.

Alternative 500 amp positive terminal connection pro-

vided on DC-1000 models above code 9500 only.

N.L.

Alternate submerged arc mode available for improved

arc stability in high current, large puddle, slow travel

procedures by making special connections on both DC-

1500 and NA-5.

On DC-1500 Control Board (G1530-2 and superseding)

remove red and blue jumpers from “FR” pins and reconnect

to corresponding “SR” pins.

On NA-5 Voltage Board (G1556-1 and superseding) white

jumper must be connected to pin “D”.

NA-5 pin “D” connection may also be used for some proce-

dures on DC-1500 without control board jumpers, DC-1500

with control board jumpers on “FR” pins or DC-1000.

Above diagram shows electrode connected positive. To change

polarity turn power off, reverse the electrode and work leads at

the power source, position the positive - negative switch on the

power source to correspond to the polarity of the electrode cable

connection. Refer to NA-5 operating manual for required NA-5

control box polarity connections.

2 1 4

2

3 1 3 2

7 3 7 4 7 5 7 6 7 7

4

G

N

D

N E G A T I V E

P O S I T I V E

2 1

N . A .

C O N T R O L C A B L E

3 2

3 1

2

C

B

A

}

}

T O N A - 5 I N P U T

C A B L E P L U G

N . J .

N . F .

N . F .

N . E .

N . K .

C O N T A C T A S S E M B L Y

F R O M N A - 5 W I R E

N . B . & N . C .

B O L T T O C A B L E S

N . D .

C O N N E C T T O W O R K

N . C . & N . H .

S16889

8-2-90F