Troubleshooting, Caution – Lincoln Electric IDEALARC IM420-D User Manual

Page 23

E-7

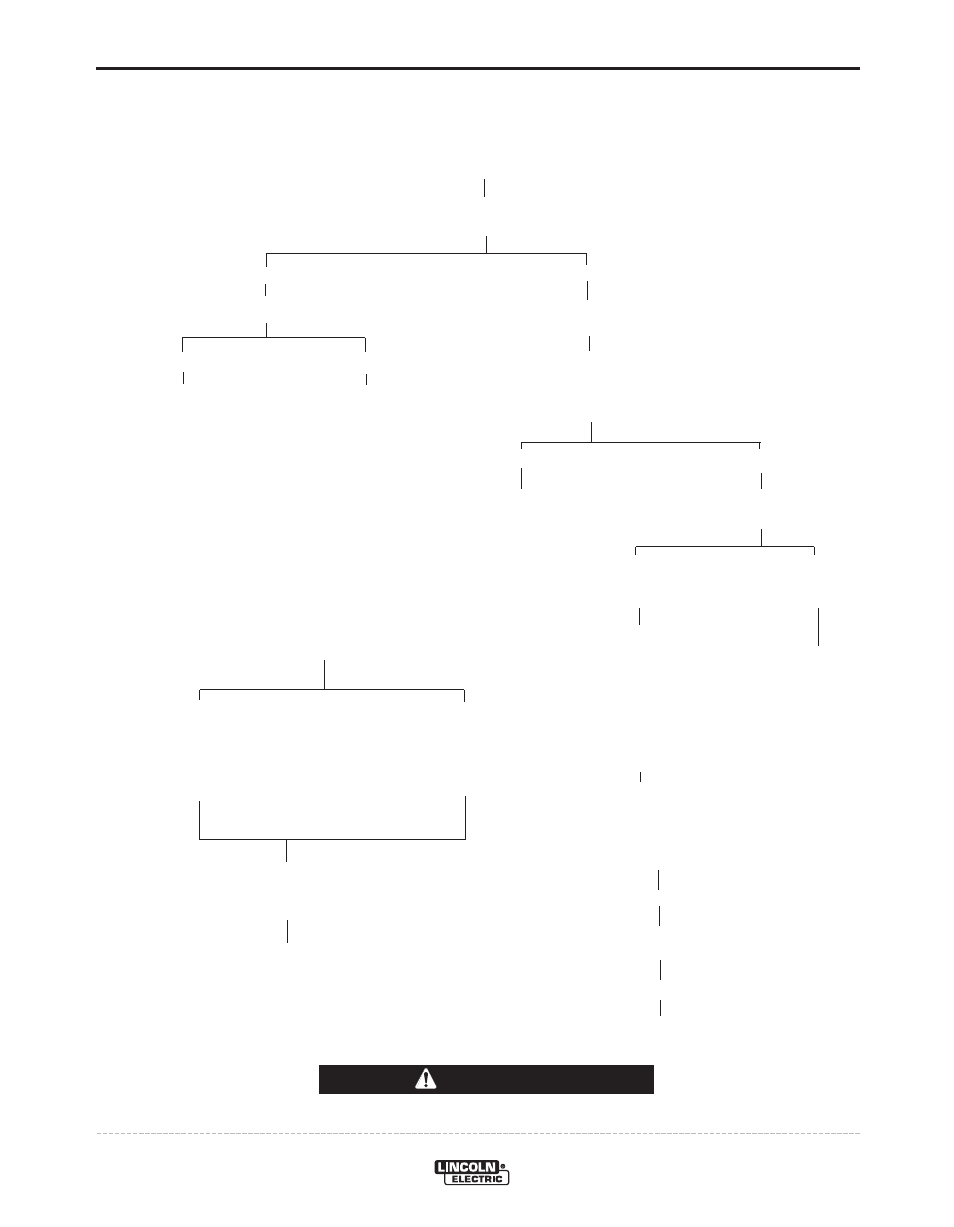

TROUBLESHOOTING

E-7

IDEALARC® DC-1000

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

MACHINE HAS OUTPUT

(Jumper 2-4) BUT TRIPS

OFF IMMEDIATELY

CHECK FOR SHORT

CHECK LEADS

BETWEEN ELECTRODE AND

73, 74, 75, 76, 77 FOR

WORK LEADS, REMOVE

GROUND TO

EXTERNAL LEADS FROM

NEGATIVE OUTPUT

THE OUTPUT TERMINALS

TERMINAL

IF TROUBLE STILL PERSISTS,

CHECK LED 3 ON

CONTROL BOARD

IF LIGHT GOES ON, THEN

QUICKLY OUT WHEN START

BUTTON IS PRESSED,

CONTROL BOARD IS

DEFECTIVE AND SHOULD

BE REPLACED

ERRATIC WELDING

CHECK PROCEDURE

CHECK MODE SWITCH FOR PROPER POSITION FOR

PROCESS BEING USED

CHECK LED’S 1 THRU 6 FOR EQUAL BRILLIANCY

IF LIGHTS ARE NOT ALL APPROXIMATELY EQUALLY

BRIGHT, REPLACE FIRING P.C. BOARD

OUTLINE FOR DC-1000 TROUBLESHOOTING GUIDE

If troubleshooting guide indicates a possible P.C.

board problem, the following guide can be used to

locate the problem.

NO WELDER OUTPUT (INPUT CONTACTOR “ON”. 2 AND 4 CLOSED)

CHECK CONTROL BOARD

LED5

IF OFF

CHECK LED1

IF ON

CHECK FIRING BOARD

LED’S

ALL

NINE LIGHTS

SHOULD

BE ON

IF OFF

IF ON

CHECK AC

REPLACE

INPUT TO

CONTROL

CONTROL

BOARD

BOARD -

POSSIBLE

DEFECTIVE

T2 TRANSFORMER

IF YES

IF NO

CHECK GATE LEAD

CHECK LIGHTS

CONNECTIONS

7,8,9

TO SCR’S

IF ONE

IF ON AND

OR MORE

OTHER LIGHTS

ARE OUT

ARE OUT

CHECK AC INPUT

TO BOARD,

REPLACE

203-204, 205-206

FIRING

207-208 -- POSSIBLE

BOARD

DEFECTIVE

AUXILIARY

WINDINGS ON MAIN

TRANSFORMER

CHECK FOR OPEN

IN LEADS 203, 204

205, 206, 207, 208