Troubleshooting – Lochinvar KNIGHT 399 User Manual

Page 32

3

Troubleshooting

32

Service Manual

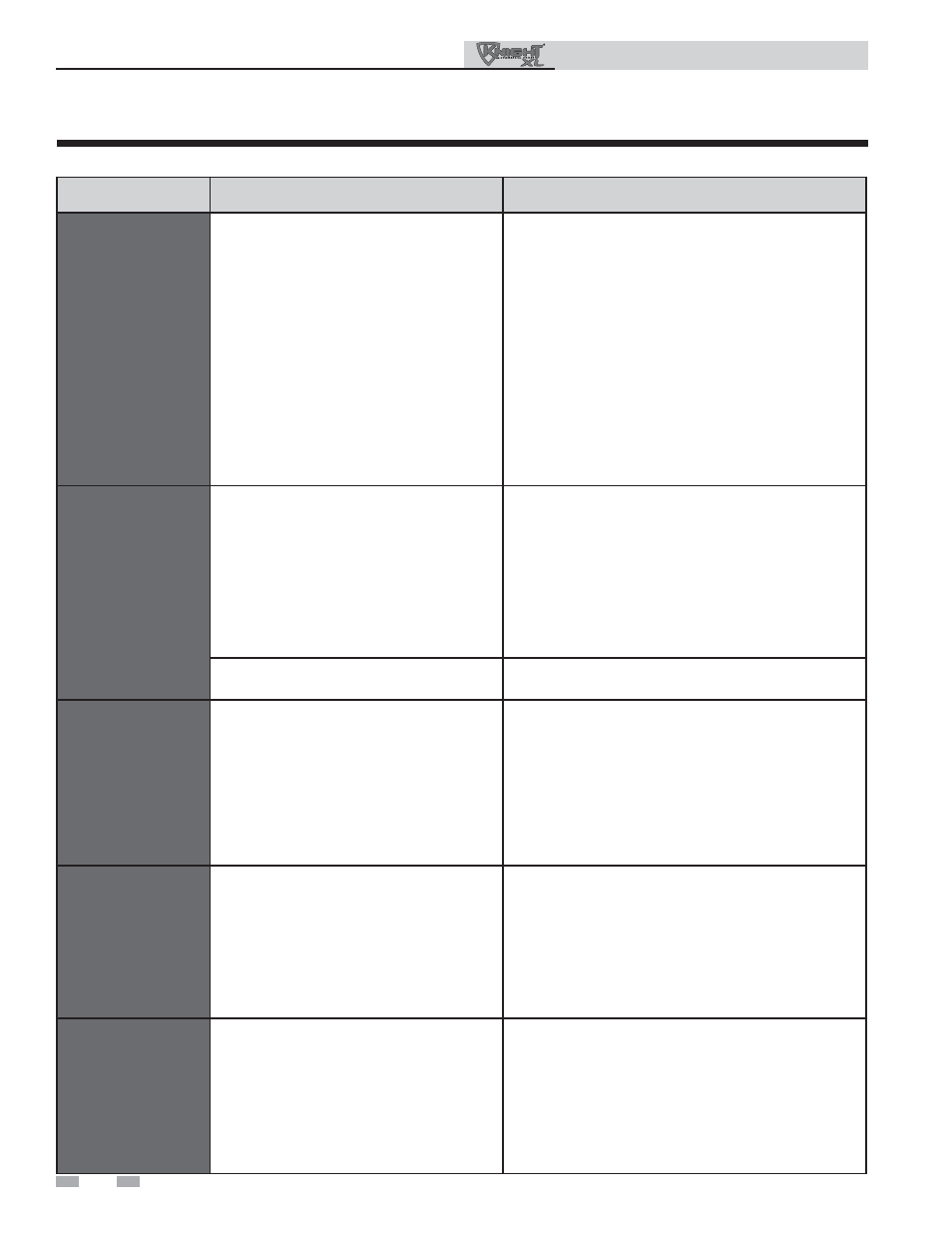

Table 3F Troubleshooting Chart - Fault Messages Displayed on Boiler Interface

FAULT

DESCRIPTION

CORRECTIVE ACTION

Gas Pressure SW

(will require a manual

reset once the condition

has been corrected.

Press the RESET button

on the SMART SYSTEM

display to reset.)

Either the optional manual reset low gas

pressure switch or the optional manual reset

high gas pressure switch tripped (not

available on 399 models).

• Reset the pressure switches.

• Measure the supply gas pressure to determine cause

of failure. Natural gas pressures should be between

4 - 14 inches w.c. (1.0 - 3.5 kPa) and LP gas

pressures should be between 8 - 14 inches w.c.

(2.0 - 3.2 kPa).

• Refer to Section 7 - Gas Connections of the Knight

XL Installation and Operation Manual for detailed

information concerning the gas supply.

• Correct the supply gas pressure if necessary.

• Check for a loose or misplaced jumper if pressure

switches are not installed.

Flow

Switch/LWCO

(will require a manual

reset once condition has

been corrected. Press

the RESET button on

the SMART SYSTEM

display to reset.)

Either the flow switch or the optional low

water cutoff is not making.

• Check boiler pump operation on a call for heat.

• Check for closed valves or obstructions in the boiler

piping.

• Verify system is full of water and all air has been

purged from the system.

• Check for loose or misplaced jumpers if flow switch or

LWCO is not installed.

Blown fuse.

• Replace fuse F2 on the control board, see page 28 of

this manual.

Blocked Drain SW

(will require a manual

reset once condition has

been corrected. Press

the RESET button on

the SMART SYSTEM

display to reset.)

The blocked drain switch has detected

excessive condensate build up inside the

unit.

• Check condensate tube from unit to floor drain for

proper installation and obstructions.

• Inspect condensate trap for blockage. Clean if

necessary.

• Check for loose wiring connection at wire harness

plug.

• Bad blocked drain switch. Replace switch.

Flame

Sequence

(will require a manual

reset once the condition

has been corrected.

Press the RESET button

on the SMART SYSTEM

display to reset.)

The flame detector circuit is seeing a flame

signal while no flame is present.

• Check supply voltage for proper polarity.

• Check external wiring for voltage feedback.

• Check the flame rod and make sure it is clean.

• Check the internal wiring for bad connections.

• Replace main control board.

GV/Relay

Fail

(will require a manual

reset once the condition

has been corrected.

Press the RESET button

on the SMART SYSTEM

display to reset.)

The main control board did not detect the gas

valve.

• Check wiring harness connection at the gas valve and

at the main control board.

• Replace the gas valve wire harness.

• Replace the gas valve.

• Replace the main control board.