Maintenance, Inspect ignition and flame sense electrodes, Check ignition ground wiring – Lochinvar KNIGHT 399 User Manual

Page 26: Check all boiler wiring, Check control settings, Perform start-up and checks, Check burner flame

2

Maintenance

26

Service Manual

Inspect ignition and flame sense

electrodes

1. Remove the ignition and flame sense electrodes from the

boiler heat exchanger access cover.

2. Remove any deposits accumulated on the ignition/flame

sense electrode using sandpaper. If the electrodes cannot

be cleaned satisfactorily, replace with new ones.

3. Replace ignition/flame sense electrode, making sure

gasket is in good condition and correctly positioned.

Check ignition ground wiring

1. Inspect boiler ground wire from the heat exchanger access

cover to ground terminal strip.

2. Verify all wiring is in good condition and securely

attached.

3. Check ground continuity of wiring using continuity

meter.

4. Replace ground wires if ground continuity is not

satisfactory.

Check all boiler wiring

1. Inspect all boiler wiring, making sure wires are in good

condition and securely attached.

Check control settings

1. Set the SMART SYSTEM control module display to

Parameter Mode and check all settings. See Section 1 of

this manual. Adjust settings if necessary. See Section 1 of

this manual for adjustment procedures.

2. Check settings of external limit controls (if any) and

adjust if necessary.

Perform start-up and checks

1.

Start boiler and perform checks and tests specified in

Section 10 - Start-up of the Knight XL Installation and

Operation Manual.

2.

Verify cold fill pressure is correct and that operating

pressure does not go too high.

Check burner flame

1.

Inspect flame through observation window.

2.

If the flame is unsatisfactory at either high fire or low fire,

turn off boiler and allow boiler to cool down. Remove

the burner and clean it thoroughly using a vacuum

cleaner or compressed air. Do not use compressed air to

clean burner if performed inside a building.

3.

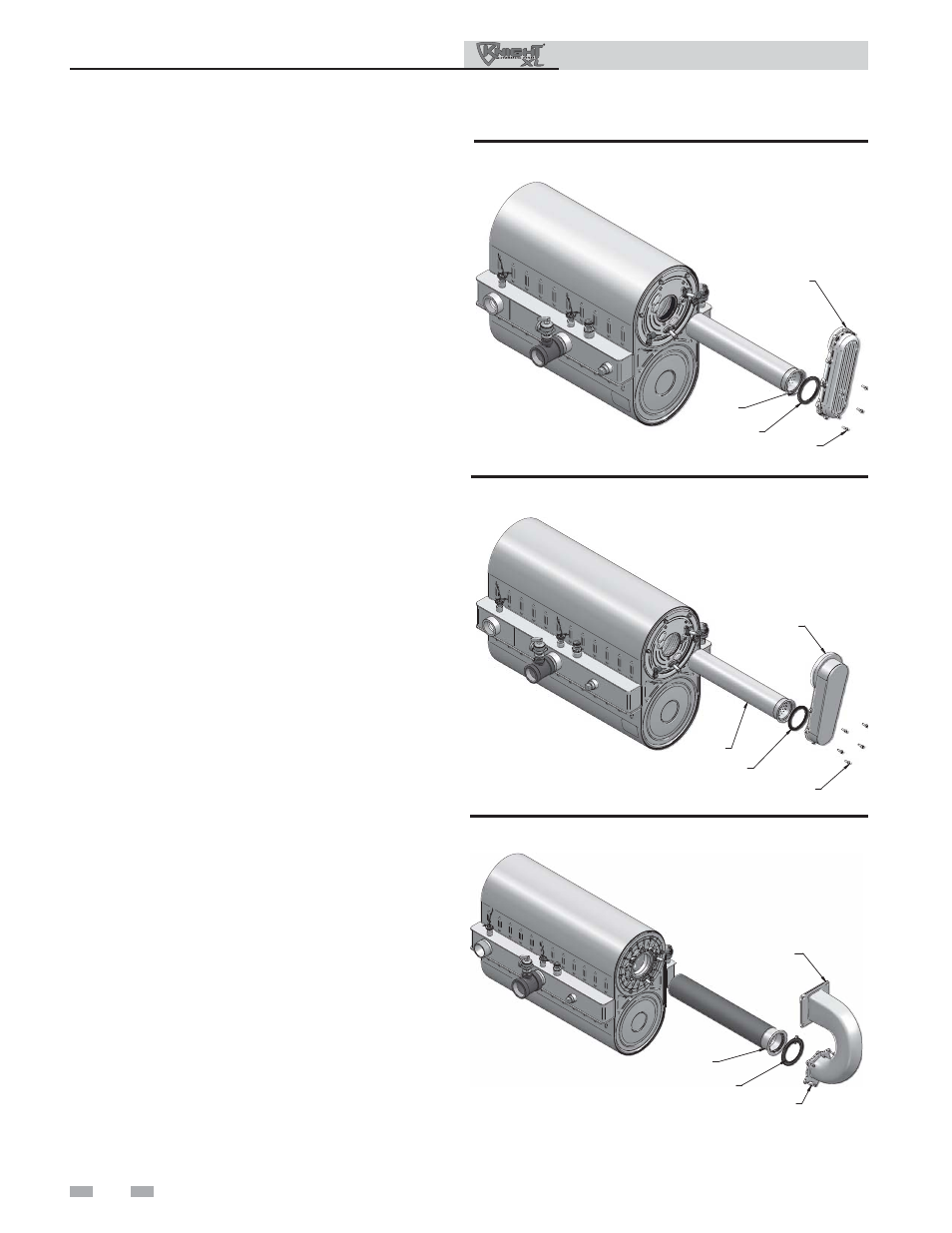

Remove the burner, reference FIG.’s 2-2 thru 2-4.

4.

When replacing the burner, ensure gasket is in good

condition and positioned correctly (FIG.’s 2-2 thru 2-4).

AIR / GAS ARM

SCREWS

(QTY. 5)

GASKET

BURNER

Figure 2-2 Burner Assembly - Model 399

BURNER

GASKET

SCREWS

(QTY. 5)

AIR / GAS ARM

Figure 2-3 Burner Assembly - Model 500

AIR ARM

SCREWS

(QTY. 5)

GASKET

BURNER

Figure 2-4 Burner Assembly - Models 600 - 800