Lennox International Inc. MERIT PLUS MPB3530CNM-B User Manual

Page 4

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOX HEARTH PRODUCTS • MERIT PLUS

®

B-VENT GAS FIREPLACES (MPB33/35/40/45) • INSTALLATION INSTRUCTIONS

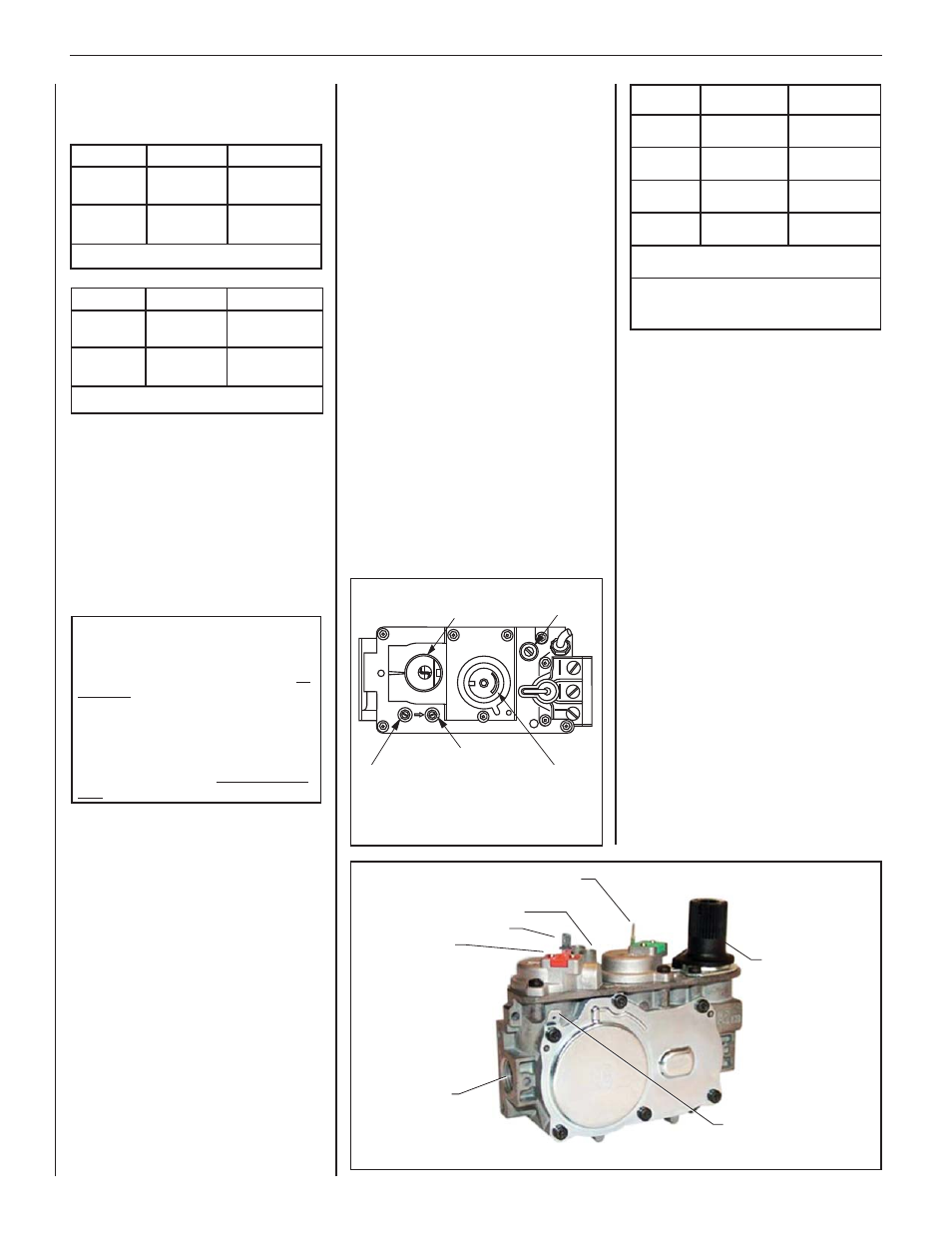

Test gauge connections are provided on

the front of the millivolt and electronic gas

control valve (identifi ed IN for the inlet and

OUT for the manifold side). The control

valves have a 3/8 in. (10 mm) NPT thread

inlet and outlet side of the valve (refer to

Figures 1 and 2).

Propane tanks are at pressures that will

cause damage to valve components. Verify

that the tanks have step down regulators to

reduce the pressure to safe levels.

ORIFICE SIZES—SEA LEVEL TO HIGH

ALTITUDE (ALL MODELS)

These appliances are tested and approved

for installation at elevations of 0–4500 ft

(0–1372 m) above sea level using the

standard burner orifi ce sizes (marked with an

"*" in Table 4). For elevations above 4500 ft,

contact your gas supplier or qualifi ed service

technician.

Deration—At higher elevations, the amount

of BTU fuel value delivered must be reduced

by either:

• Using gas that has been derated by the

gas company.

• Changing the burner orifi ce to a smaller

size as regulated by the local authorities

having jurisdiction and by the (USA)

National Fuel Gas Code NFPA 54—latest

edition / ANSI Z223.1 or, in Canada, the

CAN/CGA-B149.1 codes—latest edition.

Fuel #

Low

High

Natural Gas

1.6 in. WC

(0.40 kPa)

3.5 in. WC

(0.87 kPa)

Propane

6.3 in. WC

(1.57 kPa)

10.0 in. WC

(2.49 kPa)

Table 3: Manifold Gas Supply Pressure

The appliance and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from

the gas supply piping system by closing

its equipment shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psi (3.5 kPa).

Install the appliance according to the

regulations of the local authorities having

jurisdiction and, in the USA, the National Fuel

Gas Code NFPA 54—latest edition / ANSI

Z223.1 or, in Canada, the CAN/CGA-B149.1—

latest edition.

Flame breadth, height and width will diminish

4% for every 1,000 feet of altitude. Gas Valve

Diagrams

.

See Figure 1 for millivolt models

and Figure 2 For electronic models.

In Canada - CAN/CGA-2.17-M91 (R2009)

(high altitude): THE CONVERSION SHALL

BE CARRIED OUT BY A MANUFACTURER’S

AUTHORIZED REPRESENTATIVE, IN

ACCORDANCE WITH THE REQUIREMENTS

OF THE MANUFACTURER, PROVINCIAL

OR TERRITORIAL AUTHORITIES HAVING

JURISDICTION AND IN ACCORDANCE

WITH THE REQUIREMENTS OF THE

CAN/CGA-B149.1 OR CAN/CGA-B149.2

INSTALLATION CODES.

REQUIREMENTS FOR THE

COMMONWEALTH OF MASSACHUSETTS

These fi replaces are approved for installation

in the US state of Massachusetts if the

following additional requirements are met:

• Install this appliance in accordance with

Massachusetts Rules and Regulations

248 C.M.R.

• Installation and repair must be done by

a plumber or gas fi tter licensed in the

Commonwealth of Massachusetts.

• The fl exible gas line connector used shall

not exceed 36 in. (92 cm) in length.

• The individual manual shut-off must be a

T-handle type valve.

COLD CLIMATE INSULATION

For cold climate installations, seal all cracks

around your appliance with noncombustible

material and wherever cold air could enter the

room. It is especially important to insulate

outside chase cavity between studs and

under fl oor on which appliance rests, if fl oor

is above ground level. Gas line holes and

other openings should be caulked or stuffed

with unfaced fi berglass insulation.

If the fi replace is being installed on a

cement slab in cold climates, a sheet of

plywood or other raised platform can be

placed underneath to prevent conduction

of cold transferring to the fi replace and into

the room. It also helps to sheetrock inside

surfaces and tape for maximum air tightness

and caulk fi restops.

MANUFACTURED HOUSING

B-Vent Fireplaces are not approved for use in

OEM or aftermarket manufactured housing

built to HUD standards.

Fuel #

Minimum

Maximum

Natural Gas

4.5 in. WC

(1.12 kPa)

10.5 in. WC

(2.61 kPa)

Propane

11.0 in. WC

(2.74 kPa)

13.0 in. WC

(3.23 kPa)

Table 2: Inlet Gas Supply Pressure

GAS PRESSURE—ALL MODELS

Tables 2 and 3 show the appliances' inlet and

manifold gas pressure requirements:

H I

LO

W

HT

PT

HT

PT

PI

LOT

PI

L

O

T

ON

it

OFF

IN

OUT

HI/LO Variable

Flame Height

Adjustment

Figure 1: SIT Millivolt Gas Valve

Manifold Pressure Tap

Inlet Pressure Tap

Pilot Adjustment

Screw

Main Gas Control Knob

OFF/PILOT/ON

Orange Wire

(from DFC Wire

Harness)

Main Gas Inlet

3/8 in. NPT

Green Wire

(from DFC Wire Harness)

Inlet (IN) Test Port

Manifold (OUT) Test Port

Figure 2: SIT Electronic Gas Valve

Hi/Lo Flame

Control Knob

Yellow Ground Wire

(from DFC Wire Harness)

Model

Series

Nat.Gas

drill size (inches)

Propane

drill size (inches)

MPB33

#47 (.0785") *

99K74 •

(.048")*

99K78 •

MPB35

#44 (.086") *

60J80 •

#55 (.052") *

19L52 •

MPB40

#38 (.102") *

99K76 •

(.0625") *

21L01 •

MPB45

#36 (.104") *

24M10 •

#52 (.0635") *

37G00 •

* Standard size installed at factory

• Part /Cat. Number

Table 4: Burner Orifi ce Sizes

Elevation 0-4500 feet

(0-1372 meters)