Stick electrode typical operating procedures, Minimum preheat and interpass temperature – Lincoln Electric Stick Electrode Welding C2.410 User Manual

Page 36

-36-

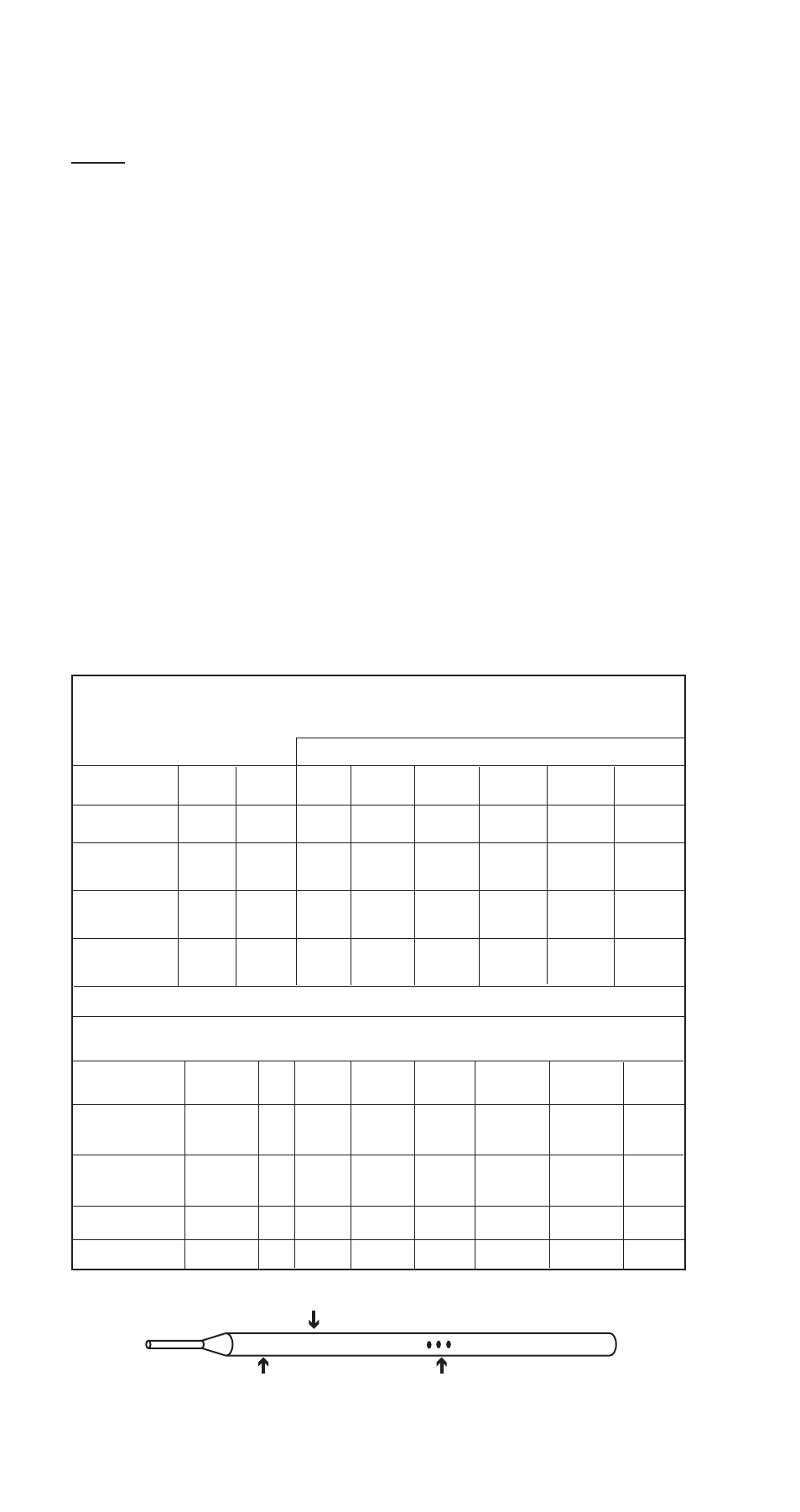

Stick Electrode Typical Operating Procedures

Sizes & Current Ranges (Amps)

Product

AWS

Electrode

Name

Class

Polarity

3 / 3 2 ”

1 / 8 ”

5 / 3 2 ”

3 / 1 6 ”

7 / 3 2 ”

1 / 4 ”

Fleetweld

®

5P

E6010

DC+

40-70

75-130

90-175

140-225

200-275

220-325

Fleetweld 5P+

E6010

DC+

40-70

65-130

90-175

140-225

---

---

Fleetweld 35

E6011

AC

50-85

75-120

90-160

120-200

150-260 190-300

DC±

40-75

70-110

80-145

110-180

135-235 170-270

Fleetweld 180

E6011

AC

40-90

60-120 115-150

---

---

---

DC±

40-80

55-110 105-135

---

---

---

Fleetweld 22

E6022

DC+

---

110-150 150-180

---

---

---

For Welding High Tensile Pipe

Shield-Arc

®

85

E7010-A1 DC+

50-90

75-130

90-175

140-225

---

---

Shield-Arc HYP+ E7010-P1 DC+

---

75-130

90-185

140-225

---

---

Shield-Arc 70+

E8010-G

DC+

---

75-130

90-185

140-225

---

---

Shield-Arc 80

E8010-G

DC+

---

75-130

90-185

140-225

160-250

---

Shield-Arc 90

E9010-G

DC+

---

75-130

90-185

140-225

---

---

“Out-of-Position” Group

All-purpose stick electrodes for general purpose fabrication and maintenance weld-

ing. Capable of x-ray quality welds out-of-position. Particularly good for vertical and

overhead. Deep penetration with maximum admixture. Light slag and flat beads

with distinctive ripples.

7018 H4R

OPTIONAL SUPPLEMENTAL

DESIGNATOR

AWS CLASS (OR NAME)

ON EACH ELECTRODE

LOOK FOR LINCOLN'S

SYMBOL OF DEPENDABILITY

Minimum Preheat and Interpass Temperature

(1) Continued

For stick electrode welding only

Based on AWS Specification D1.1

Notes

(1) Welding shall not be done when ambient temp. is lower than 0ºF.

Parts on which metal is being deposited shall be at or above the

specified temperature for a distance equal to the thickness of the part

being welded, but not less than 3”, in all directions from the point of

welding. Preheat and interpass temperature must be sufficient to

prevent cracking. Temperature above the minimum may be

required for highly restrained welds. For ASTM A709 Grade 70W

and ASTM A852 Grade 70, the maximum preheat and interpass tem-

perature shall not exceed 400ºF for thicknesses thru 1-1/2”, and

450ºF for greater thicknesses.

(2) When the base metal temperature is below 32ºF, preheat to at least

70ºF and maintain this minimum temperature during welding.