Corner welds -22 – Lincoln Electric Stick Electrode Welding C2.410 User Manual

Page 22

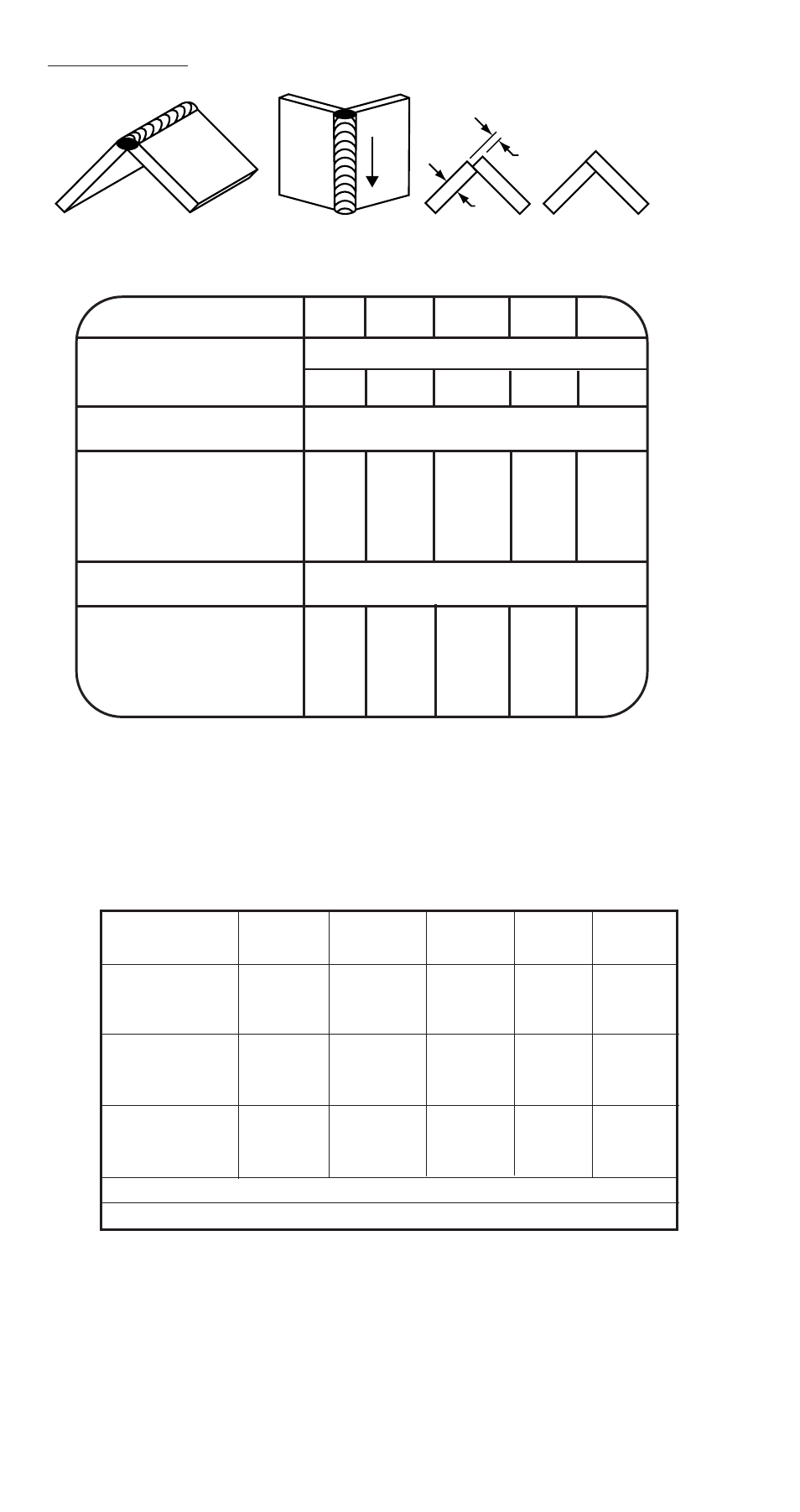

Corner Welds

-22-

Weld Type/

Position

18ga

16ga

14ga

12ga

10ga

Fillet Welds

0-30º

15

16

17

16

16

30-90º

18

19

21

20

18

Lap Welds

0-30º

17

18

18

16

15

30-60º

21

22

23

21

18

Groove Welds

0-30º

22

30

29

27

25

30-60º

26

32

30

29

27

Edge Welds - Same as DC

Corner Welds - Same as DC

Flat

Vertical

(welded down)

18 to

10 gauge

Permissible for

18 & 16 gauge

1/2 T

T

Plate Size

18ga

16ga

14ga

12ga

10ga

Electrode/AWS Class

Fleetweld 5P, Fleetweld 5P+ /E6010

Diameter (in.)

3/32

1/8

1/8

5/32

3/16

Position

(1)

0-30° Downhill

Current (Amps)

45

80

85

110

155

Polarity

(2)

DC-

DC-

DC-

DC-

DC+

Arc Speed - In./Min.

(3)

33

38

38

36

30

Lbs of Elec./Ft. of Weld

.020

.028

.030

.043

.051

Position

(1)

30-90° Downhill

Current (Amps)

50

90

95

120

170

Polarity

(2)

DC-

DC-

DC-

DC-

DC+

Arc Speed In./Min.

(3)

38

43

43

40

36

Lbs. of Elec./Ft. of Weld .018

.028

.029

.044

.046

(1) 45 to 75º downhill position is recommended for easy welding and fast

speeds. Corner welds on 10 gauge steel can be welded 5-7 in./min. faster

when positioned 75 to 90º downhill rather than 45 to 75º downhill.

(2) For AC welding use:

a. E6011 in place of E6010 or E6013 in place of E6012

b. The same electrode diameters.

c. About 10% higher current.

d. The following arc speeds:

(3) For ft. of weld/hr. multiply in./min. by 5. 100% operating factor.

Arc Speed (inch/min)