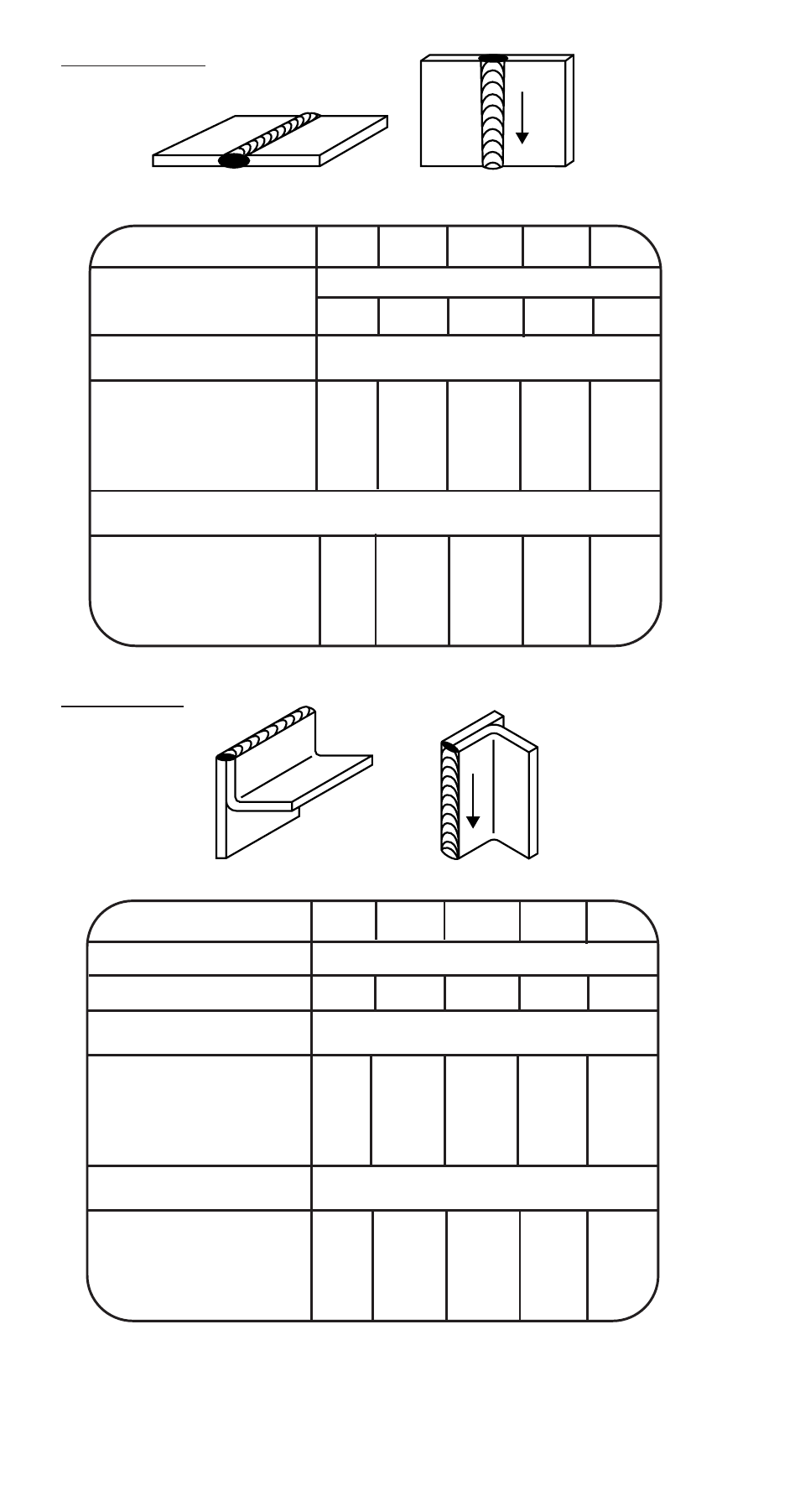

Groove welds edge welds – Lincoln Electric Stick Electrode Welding C2.410 User Manual

Page 20

-20-

Plate Size

18ga

16ga

14ga

12ga

10ga

Electrode/AWS Class Fleetweld 5P, Fleetweld 5P+ /E6010

Diameter (in.)

3/32

1/8

1/8

5/32

3/16

Position

(1)

0-30° Downhill

Current (Amps)

40

70

80

120

135

Polarity

(2)

DC-

DC-

DC+

DC+

DC+

Arc Speed - In./Min.

(3)

24

32

28

22

19

Lbs of Elec./Ft. of Weld

.024

.029

.026

.049

.070

Position

(1)

30-90° Downhill

Current (Amps)

45

75

90

130

150

Polarity

(

2)

DC-

DC-

DC+

DC+

DC+

Arc Speed In./Min.

(3)

28

36

30

25

20

Lbs. of Elec./Ft. of Weld .023

.028

.027

.048

.073

Groove Welds

Edge Welds

Flat

Vertical (welded down)

Flat

Vertical (welded down)

(1) 45 to 75° downhill position recommended for easy operation and fast speeds.

(2) AC can be used – see page 22.

(3) For ft. of weld/hr. multiply in./min. by 5. 100% operating factor.

Plate Size

18ga

16ga

14ga

12ga

10ga

Electrode/AWS Class

Fleetweld 5P, Fleetweld 5P+ /E6010

Diameter (in.)

3/32

1/8

1/8

5/32

3/16

Position

(1)

0-30° Downhill

Current (Amps)

50

80

85

115

140

Polarity

(

2)

DC-

DC-

DC-

DC-

DC-

Arc Speed - In./Min.

(3)

48

46

43

43

40

Lbs of Elec./Ft. of Weld

.015

.023

.026

.038

.048

Position

(1)

30-90° Downhill

Current - Amps

55

90

95

125

155

Polarity

(2)

DC-

DC-

DC-

DC-

DC-

Arc Speed In./Min.

(3)

56

53

50

50

46

Lbs. of Elec./Ft. of Weld .014

.023

.025

.036

.047