Prepare boiler – Lochinvar KNIGHT 51 User Manual

Page 12

Installation & Operation Manual

2

Prepare boiler

12

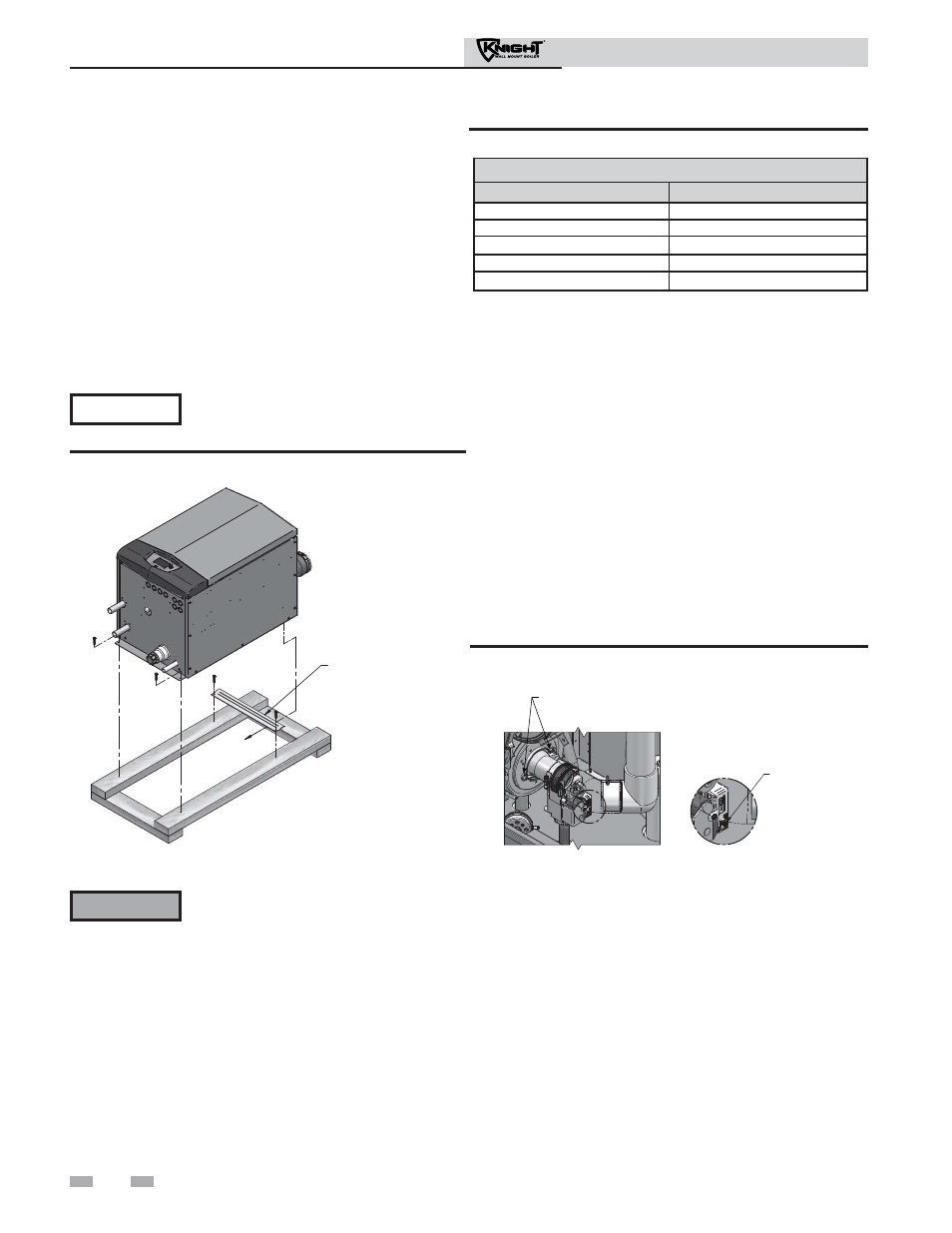

Remove boiler from wood pallet

1.

After removing the outer shipping carton from the boiler,

remove the parts box.

2.

To remove the boiler from the pallet:

a.

Remove the two (2) lag bolts securing the bottom

of the unit to the pallet.

b.

Lift the boiler off the wall bracket mounted to

the pallet.

3.

Remove the two (2) lag bolts securing the wall bracket to

the wood pallet. Be certain not to lose the wall bracket as

it will be needed for securing the boiler to the wall

(FIG. 2-1).

Do not drop the boiler or bump the jacket

on the floor or pallet. Damage to the

boiler can result.

The gas conversion procedure should be

accomplished BEFORE the boiler is

installed. For a boiler already installed,

you must turn off gas supply, turn off

power, and allow the boiler to cool before

proceeding. You must also completely test

the boiler after conversion to verify

performance as described under Start-up,

Section 10 of this manual.

You must install the propane orifice to fire

the Knight wall mount boiler on propane.

Verify when installing that the orifice size

marking matches boiler size (Table 2A).

Failure to comply could result in severe

personal injury, death, or substantial

property damage.

1. Remove the front access cover from the unit (no tools

required for removal).

2. Disconnect the ribbon cable from the control board.

Remove the four (4) screws securing the bezel to the front of

the unit and remove the bezel.

3. Locate the power switch on the gas valve and turn the power

switch to the “OFF” position (FIG. 2-2).

4. Disconnect the Molex plug from the wiring connector

located on the gas valve.

5. Using a 5/16" nut driver, loosen the band clamp securing the

air intake coupler to the gas valve venturi. Remove the air

intake pipe and coupler from the gas valve venturi.

6. Using a 4mm Allen wrench, remove the two (2) screws

securing the gas valve venturi to the inlet of the combustion

blower (FIG. 2-2). Remove the gas valve venturi assembly

from the unit.

DO NOT DISCARD-

WILL BE NEEDED TO

SECURE THE BOILER

TO THE WALL

REMOVE SHIPPING

[WALL] BRACKET

Figure 2-1 Boiler Mounted on Shipping Pallet

Gas conversions

LP Conversion Table

Model

LP Orifice Stamping

51

50

81

80

106

105

151

210 / W150

211

210 / W150

NOTICE

ƽ WARNING

Table 2A LP Conversion Table

Figure 2-2 Gas Valve Power Switch & Venturi Removal

DETAIL

POWER SWITCH

REMOVE THE TWO (2) SCREWS

SECURING THE GAS VALVE VENTURI

TO THE INLET OF THE COMBUSTION BLOWER

7. Using a 4mm Allen wrench, remove the four (4) screws

securing the gas valve to the venturi (FIG. 2-3).

8. Locate the propane orifice disk from the conversion kit bag.

Verify that the stamping on the orifice disk matches the

boiler size (51 - 211, see Table 2A).

9. Place the orifice into the black rubber grommet in the side of

the gas valve and secure inside the gas valve (see FIG. 2-3).

10. Reposition the gas valve against the venturi and replace the

four (4) screws removed in Step 7, securing the valve to the

venturi (FIG. 2-3).

11. Reposition the gas valve venturi assembly inside the unit.

Secure the gas valve venturi to the combustion blower by

replacing the two (2) screws removed in Step 6 (FIG. 2-2).

12. Reattach the air intake pipe and coupler to the gas valve

venturi. Tighten the band clamp to secure.