See fault code explanations, Troubleshooting & repair – Lincoln Electric POWER WAVE 355/405 SVM159-A User Manual

Page 52

POWER WAVE 355/405

TROUBLESHOOTING & REPAIR

F-10

F-10

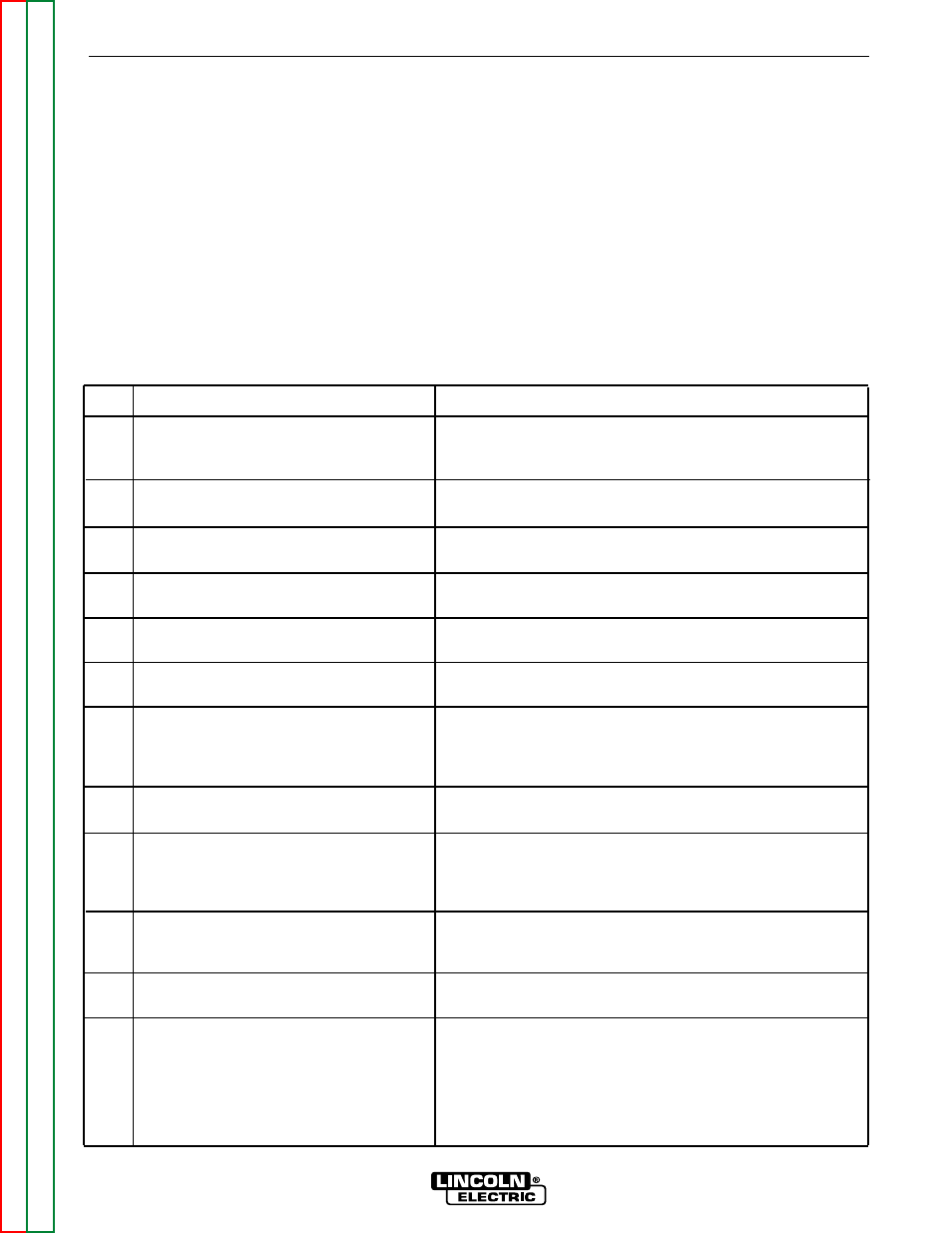

STATUS LED ERROR CODE TABLE

NOTE: The error code signal sequence is always preceded by a 2 second green light. If more than one error

code is present, a 4 second off signal will separate the individual error code signals. Note that the

[2 sec. green] is only displayed at the beginning of the entire code sequence, not between codes if

more than one error code is present.

Example: (Code. #11 “one long red” followed by “one short red”) followed by (Code. #21 “two long reds” fol-

lowed by “one short red”).

[2 sec. green] [1.2 sec. red] [1.6 sec. off] [0.4 sec. red] [4.0 sec. off] [1.2 sec. red] [0.4 sec. off]

[1.2 sec. red] [1.6 sec. off] [0.4 sec. red]

ERROR CODES FOR THE POWER WAVE

The following is a list of possible error codes that the POWER WAVE 355/405 can output via the status light

(see “Troubleshooting the Power Wave / Power Feed System using the Status LED.” If connected to a PF-

10/11 these error codes will generally be accompanied by an “Err 006” or “Err 100” on the user interface

display.

11

12

CAN communication bus off.

User interface time out error.

Probably due to excessive number of communication errors.

UI is no longer responding to the Power Source. The most

likely cause is a fault/bad connection in the communication

leads or control cable.

21

Unprogrammed weld mode.

Contact the service department for instructions on reloading

the Welding Software.

22

Empty weld table.

Contact the service department for instructions on reloading

the Welding Software.

23

Weld table checksum error.

Contact the service department for instructions on reloading

the Welding Software.

31

Primary overcurrent error.

Excessive Primary current present. May be related to a

short in the main transformer or output rectifier.

32

Capacitor “A” under voltage.

Low voltage on the main capacitors. May be caused by

improper input configuration.

33

Capacitor “B” under voltage.

When accompanied by an overvoltage error on the same

side, it indicates no capacitor voltage present on that side,

and is usually the result of an open or short in the primary

side of the machine.

34

Capacitor “A” overvoltage.

Excessive voltage on the main capacitors. May be caused

by improper input configuration.

35

Capacitor “B” overvoltage.

When accompanied by an under voltage error on the same

side, it indicates no capacitor voltage present on that side,

and is usually the result of an open or short in the primary

side of the machine.

36

Thermal error.

Indicates over temperature. Usually accompanied by ther-

mal LED. Check fan operation. Be sure process does not

exceed duty cycle limit of the machine.

37

Softstart error.

Capacitor precharge failed. Usually accompanied by codes

32-35.

41

Secondary overcurrent error

The secondary (weld) current limit has been exceeded.

When this occurs the machine output will phase back to

100 amps, typically resulting in a condition referred to as

“noodle welding”

NOTE: The secondary limit is 570 for the standard stud, and

325 amps for all single phase operation.