Theory of operation, Switch board & main transformer – Lincoln Electric POWER WAVE 355/405 SVM159-A User Manual

Page 37

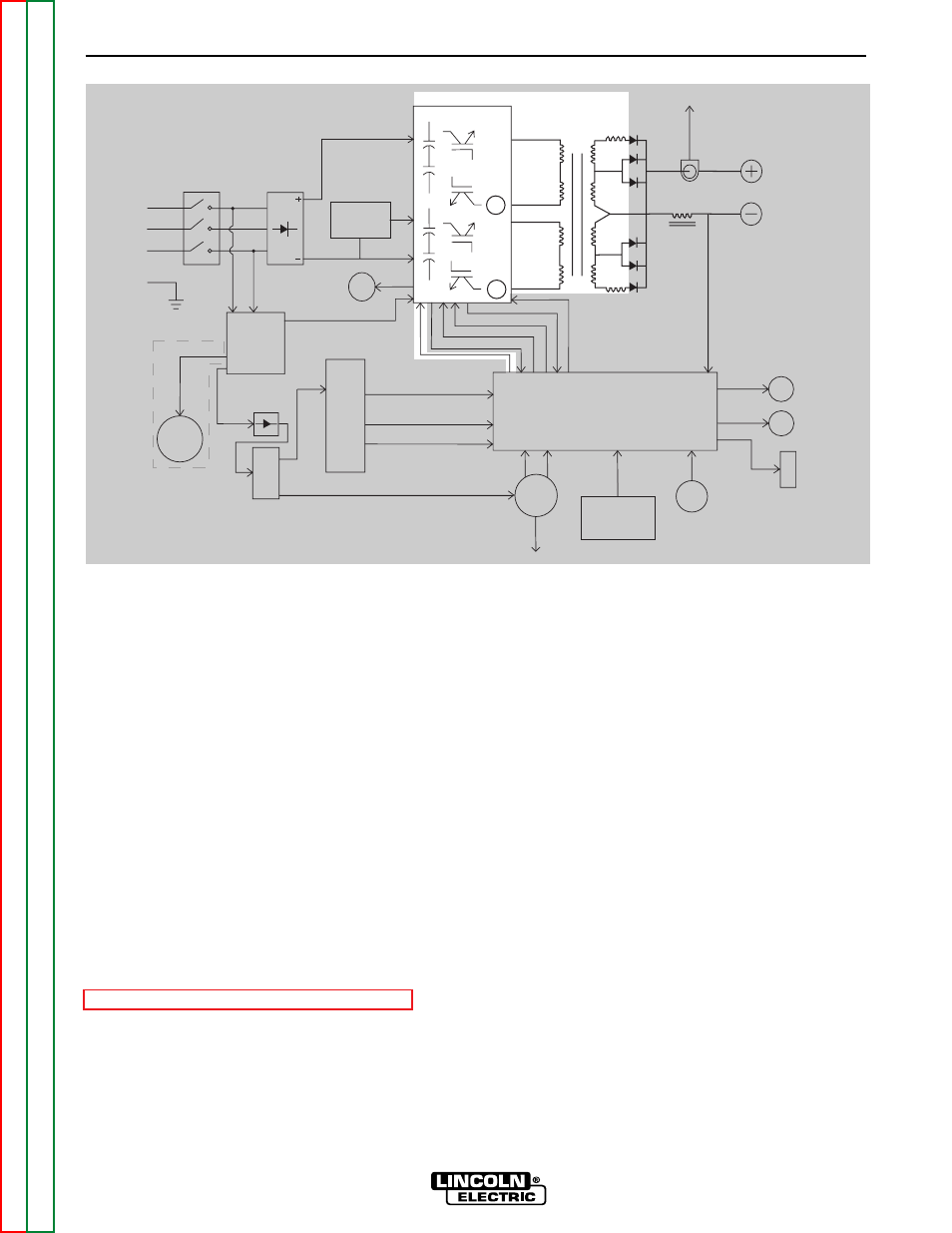

SWITCH BOARD &

MAIN TRANSFORMER

There is one switch board in the POWER WAVE

355/405. This board incorporates two pairs of input

capacitors, two insulated gate bipolar transistor (IGBT)

switching circuits, a fan motor drive circuit, and a volt-

age/frequency capacitor feedback circuit. The two

capacitors in a pair are always in series with each

other. When the reconnect switch is in the lower volt-

age position the capacitor pairs are in parallel . Thus

two series capacitors in parallel with two series capac-

itors. When the reconnect switch is in the high voltage

position the two capacitor pairs are in series. Thus

four capacitors in series. This is required to accom-

modate the higher input voltages.

When the input capacitors are fully charged they act

as power supplies for the IGBT switching circuits.

When welding output is required the Insulated Gate

Bipolar Transistors switch the DC power from the input

capacitors, "on and off" thus supplying a pulsed DC

current to the main transformer primary windings. See

IGBT Operation Discussion and Diagrams in this

section. Each IGBT switching circuit feeds current to

a separate, oppositely wound primary winding in the

main transformer. The reverse directions of current

flow through the main transformer primaries and the

offset timing of the IGBT switching circuits induce an

AC square wave output signal at the secondary of the

main transformer. The two current transformers (CT)

located on the switch board monitor these primary

currents. If the primary currents become abnormally

high the control board will shut off the IGBTs, thus dis-

abling the machine output. The DC current flow

through each primary winding is clamped back to

each respective input capacitor when the IGBTs are

turned off. This is needed due to the inductance of the

transformer primary winding. The firing of the two

switch boards occurs during halves of a 50 microsec-

ond interval, creating a constant 20 KHZ output. In

some low open circuit Tig modes the firing frequency

is reduced to 5KHZ.

The POWER WAVE 355/405 has a F.A.N. fan as need-

ed circuit. The fan operates when the welding output

terminals are energized or when a thermal over tem-

perature condition exists. Once the fan is activated it

will remain on for a minimum of five minutes. The fan

driver circuit is housed on the switch board but it is

activated from a control board signal.

THEORY OF OPERATION

E-3

E-3

POWER WAVE 355/405

FIGURE E.3 – SWITCH BOARD & MAIN TRANSFORMER

Control Board

Choke

Positive

Output

Terminal

Negative

Output

Terminal

To Control

Board

Current

Feedback

Reconnect

Switch

Output V

oltage Sense

Input switch

Input

Rectifier

Auxiliary

Transformer

Fan

Power

Board

220

Receptacle

RS232 Supply +5VDC

Machine Control Supply

+15VDC, -15VDC, +5VDC

40VDC

42VAC

220 VAC

Main Switch Board

115VAC Fan Supply

Fan Control

V/F Capacitor Feedback (2)

Soft Start Control

Input Relay Control

Primary Current Feedback(2)

IGB

T D

rive S

ignal

Primary

Current

Sensor

Primary

Current

Sensor

{

P

o

w

e

r

W

a

v

e

4

0

5

o

n

l

y

65V

AC

DC

Bus

Board

Wire

Feeder

Recp.

40VDC

Can Supply +5VDC

Arc

Link

Electrode

Sense

21 Lead

Voltage

Sense

Recp.

R232

Connector

Yellow

Thermal

LED

Status

Red/Green

LED

Thermostats

2

To