Table saw operations, Se rv ic e – Woodstock SHOP FOX W1677 User Manual

Page 51

-49-

W1677/W1711 10" Table Saw

SE

RV

IC

E

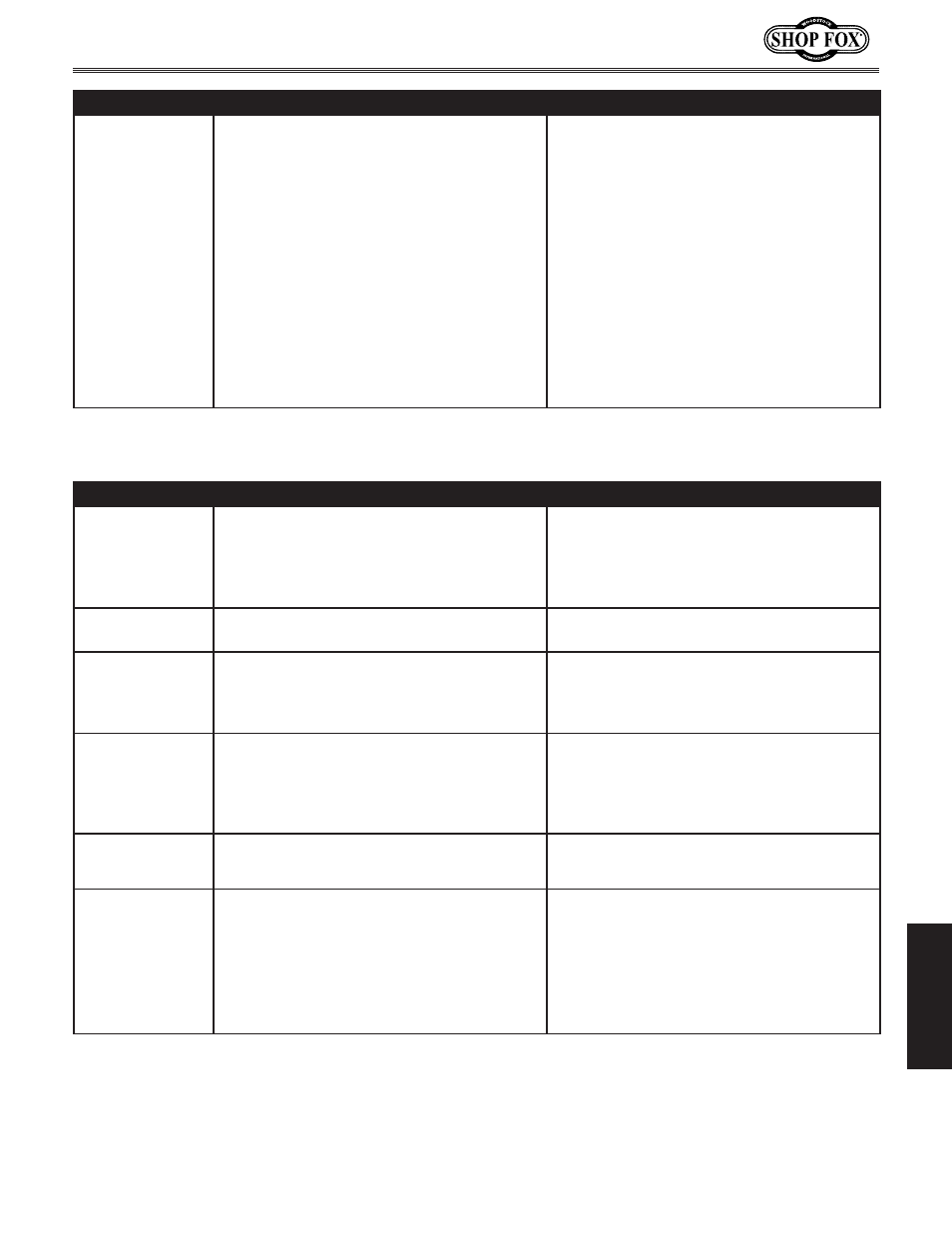

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Machine has vibra-

tion or noisy opera-

tion.

1. Loose arbor nut.

1. Tighten the arbor nut.

2. Blade is damaged.

2. Replace warped, bent, or twisted blade.

3. Blade is too thin.

3. Use blade stabilizers.

4. Machine is sitting on an uneven floor.

4. Relocate machine or shim feet.

5. Belt is worn or is loose.

5. Inspect belt, replace or re-tension (

Page 45).

6. Pulley is loose.

6. Remove pulley; replace shaft, pulley, and set

screw as required, and re-align.

7. Wrong workpiece material (wood).

7. Only cut wood with correct moisture content,

with no pitch, glues, or resins.

8. Cast iron motor mount is damaged.

8. Carefully using leverage and a small pry bar,

carefully look for loose/broken mounts and

replace if necessary.

9. Arbor bearings are damaged.

9. Replace arbor housing bearings.

10. Motor bearings are damaged.

10. Replace motor bearings.

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Blade is not aligned

with miter slot or

fence.

1. Blade is warped.

1. Replace blade.

2. Blade is not parallel to table top.

2. Adjust table top (miter slot) parallel to blade

(

Page 41) or adjust blade parallel to table

(

Page 40).

3. Fence is not parallel to blade.

3. Make fence parallel to blade (

Page 45).

Fence hits table top

when sliding.

1. Front rail is bolted too low on table.

1. Raise front rail.

2. Rear rail is bolted too low on the table.

2. Raise rear rail.

Blade does not reach

90°.

1. 90° stop bolt is out of adjustment.

1. Adjust 90° stop bolt (

Page 39).

2. Pointer bracket is hitting before the blade

reaches 90°.

3. Sawdust loaded up on positive stop.

2. File down the right side of the pointer bracket

until the blade can reach 90°.

3. Clean sawdust off positive stop.

Blade hits insert at

45°.

1. Hole in insert is inadequate.

1. File or mill the hole in the insert.

2. Table out of alignment.

2. Adjust table top (miter slot) parallel to blade

(

Page 41) or adjust blade parallel to table

(

Page 40).

3. Blade position is incorrect.

3. Adjust blade position.

Blade will not go

beneath table sur-

face.

1. Table top too low.

1. Raise table by shimming w/washers.

Board binds or

burns when feeding

through tablesaw.

1. Dull blade.

1. Replace blade (

Page 25).

2. Blade is warped.

2. Replace blade (

Page 25).

3. Splitter out of alignment.

3. Align the splitter with the blade (

Page 43).

4. Fence is not parallel to blade.

4. Make fence parallel to blade (

Page 45).

5. Table top is not parallel to blade.

5. Adjust table top (miter slot) parallel to blade

(

Page 41) or adjust blade parallel to table

(

Page 40).

Table Saw Operations