Scag Power Equipment MAG User Manual

Page 24

22

3. After proper tension is obtained, tighten the two bolts

and install the pump belt guard.

6.6 PUMP DRIVE BELT ADJUSTMENT

To adjust belt tension, turn the adjusting nut (Figure 6-1)

until 1/2 inch deflection in belt is obtained with 10 pounds

of pressure. See Engine Drive Belts, section 7.9 for checking

method.

6.7 ELECTRIC CLUTCH DRIVE BELT

ADJUSTMENT

To adjust the belt tension, turn the adjusting nut (Figure 6-

4) to obtain 1/2 inch belt deflection with 10 pounds of

pressure. See Engine Drive Belts, section 7.9 for checking

method.

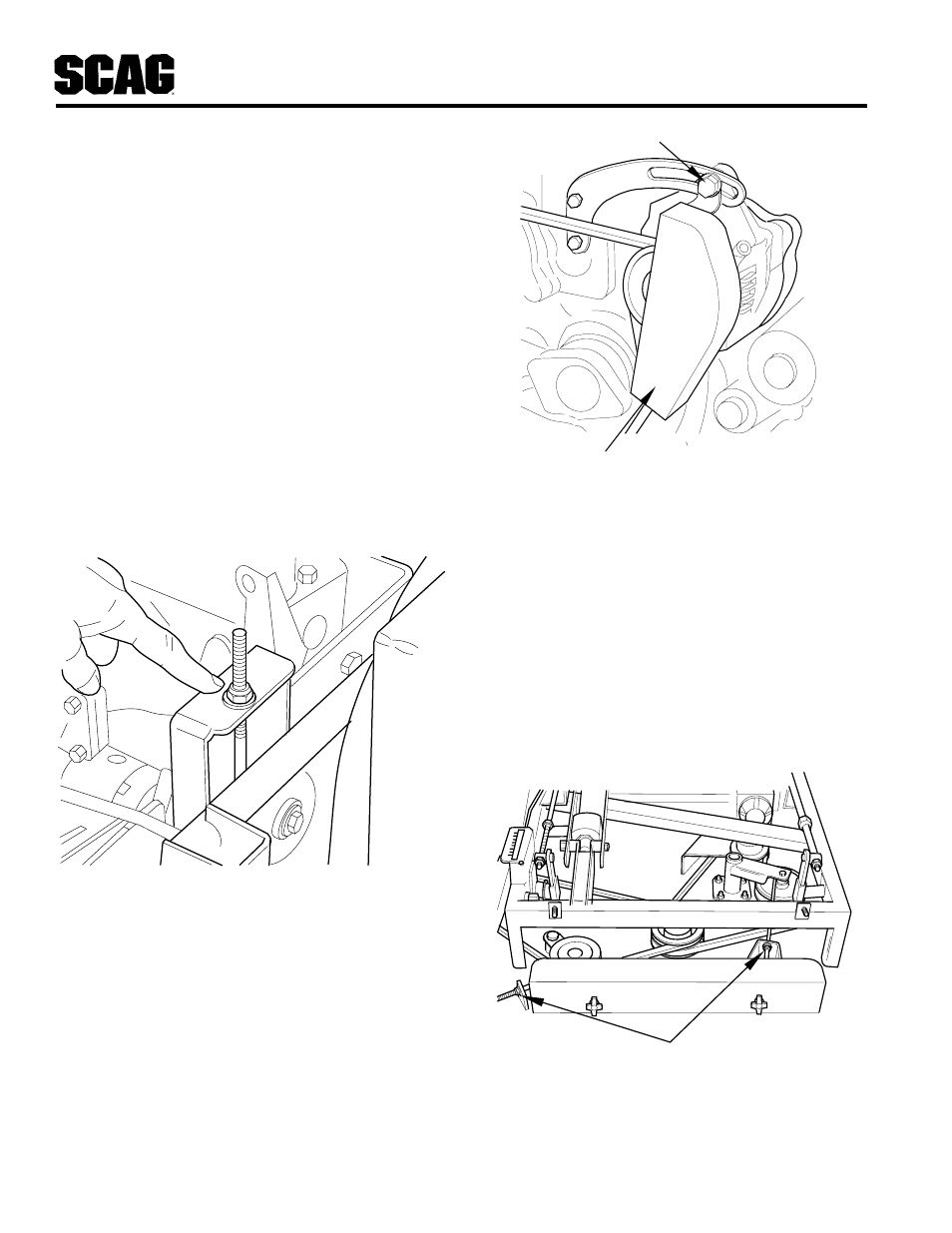

Figure 6-5 Alternator Belt Adjustment

6.9 CUTTER DRIVE BELT ADJUSTMENTS

1. Remove the top cutter deck cover.

2. Each belt has an adjustment rod attached to its belt

idler arm. To adjust the belt tension, turn the adjusting

nut (Figure 6-6) until 1/2 inch deflection in the belt is

obtained with 10 pounds of pressure. See Cutter Deck

Belts, section 7-10 for checking method.

Figure 6-6 Blade Belt Tension Adjustments

(Mag-72 Deck Shown)

3. Replace the top cutter deck cover.

Figure 6-4 Electric Clutch Drive Belt Adjustment

6.8 ALTERNATOR BELT ADJUSTMENT

To adjust the alternator belt tension, loosen the two bolts

holding the alternator (Figure 6-5). Move the alternator

until proper tension of 0.28 to 0.35 inch deflection with 22

pounds of pressure is obtained, then tighten the two bolts.

See Engine Drive Belts, section 7.9 for checking method.

Adjusting Bolt

Adjusting Bolt

Location

Tension Adjusting Nuts

Section 6