Base mounting, Through-bolt option, Direct mount option – Woodstock W1764 User Manual

Page 17: Quick holder kit option, Se tu p

-15-

W1764 Power Feeder

SE

TU

P

To correctly position this power feeder on your table top,

completely assemble the power feeder first, then refer

this section and mount your base to the table using one

of the three methods below. The reason for this order, is

that with the power feeder unit completely assembled, it

will be easier to locate where on the table top you will

need to drill your base mounting holes, so you can take

advantage of the full range of power feeder swing and

adjustments.

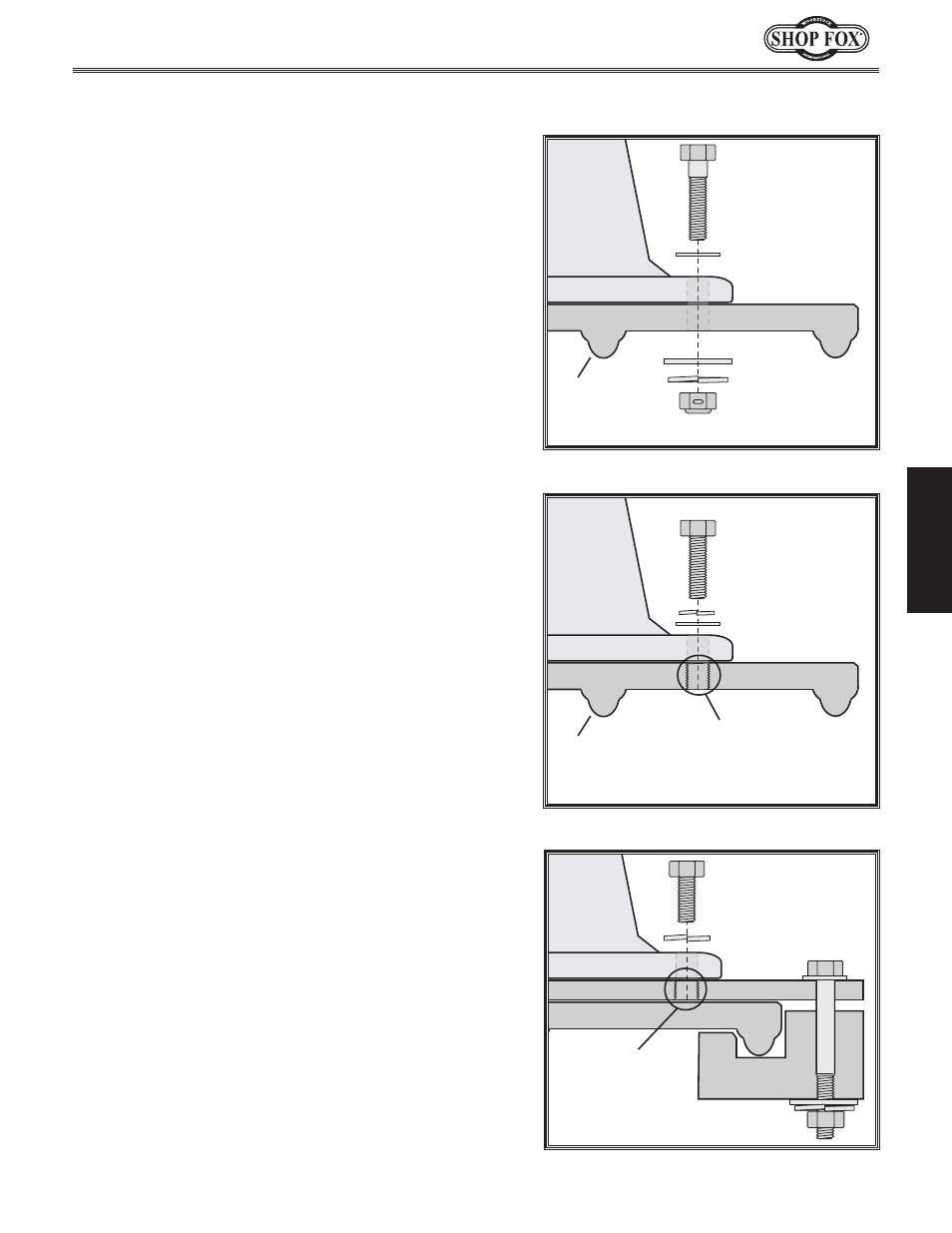

Through-Bolt Option

We recommend that you mount your new power feeder

to the machine table with through bolts, nuts and wash-

ers (

Figure 14). This option will give the most rigidity and

clamping strength to prevent the feeder base from twist-

ing out of alignment during use. However, if the included

mounting bolt template shows that any under-table sup-

port webs will interfere with any washer or nut locations

under the table, you will have to use an optional clamping

kit, or drill and thread holes directly into the table as

described in the

Direct Mount Option paragraph below.

Direct Mount Option

You may choose to use the included mounting template

and drill and tap your table, so the power feeder base

can be directly mounted to the table surface (

Figure 15).

But make sure that the machine cast-iron table is no less

than

3

⁄

8

" thick where the threaded holes are drilled and

tapped. If the table is any thinner, you run the risk of

having shallow and weak threads that will allow the bolts

to loosen as the power feeder is used. Thread locking

compound will not cure this problem. Do not drill and tap

into any table support webs or table supports to compen-

sate for a thin table, or you will weaken the table and

possibly cause cracking. Revert to either the

Through-

Bolt Option or the Quick Holder Kit Option if the table is

too thin or if support webbing is in the way. In any case,

make sure to use an automotive-grade liquid thread lock-

ing compound on all threads.

Quick Holder Kit Option

For temporary or permanent installation of your power

feeder without drilling into the table, you can purchase

and install the Model D3868 Quick Holder Kit (

Figure 16).

These kits, while not as rigid as the through-bolt or direct

mount options, require no drilling or tapping, and are

adequate for most power feeder applications. Make sure

to use an automotive-grade liquid thread locking com-

pound on all threads.

Figure 14. Through-bolt mounting.

Machine Table

Flat Washer

Flat Washer

Lock Washer

Locking Hex Nut

Table

Support

Webbing

Bolt

Feeder

Base

Machine Table

Lock Washer

Feeder

Base

Quick Holder

Quick

Holder

Bolt

Apply Medium

Grade Thread

Locking Compound

to the Threads

Figure 16. Quick holder mounting.

Figure 15. Direct mounting.

Machine Table

Table

Support

Webbing

Bolt

Feeder

Base

Lock Washer

Flat Washer

Apply Medium

Grade Thread

Locking Compound

to the Threads

Base Mounting