Autoreset after a trip, Emergency restarting, Using the hand held communicator – Siemens MCC-3298 User Manual

Page 26: Described in detail in section 3.27, 3 operating the samms-lv device, 25 autoreset after a trip (samms-lvx only), 26 emergency restarting, 27 using the hand held communicator (hhc)

24

3 Operating the SAMMS-LV Device

the motor trips and the Ground Fault LED illuminates until reset.

If you selected warning (OFF), the Ground Fault LED flashes as

long as the fault current exceeds the pickup level. Table 3.6 lists

the pickup levels for each overload size. Ground fault protection

is locked out for the overload class time.

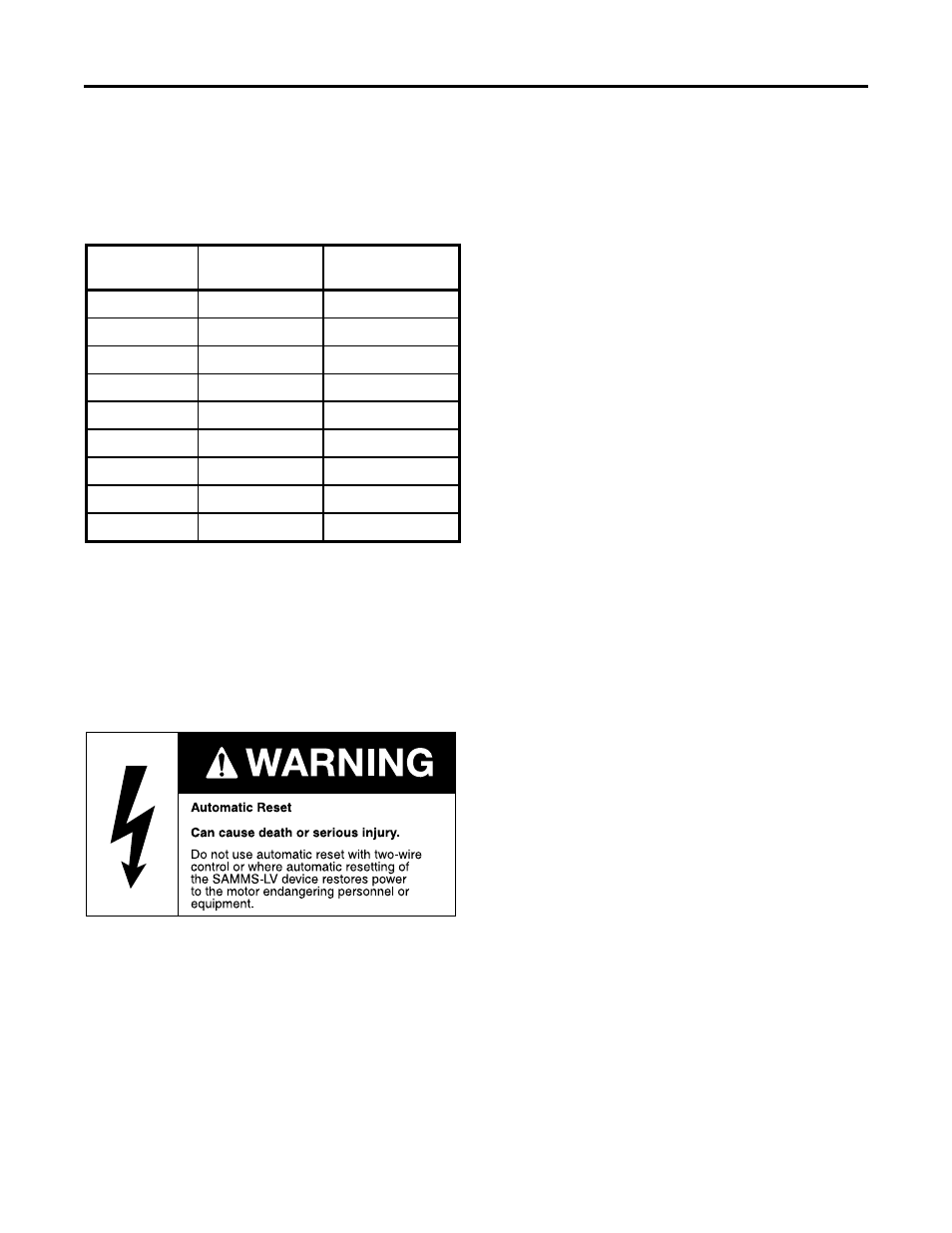

Size

Pickup Current

Range

Default Pickup

Current

1A

1.5A

1.5A

1B

2A to 5A

5A

1C

2A to I

5A

2A

2A to I

10A

2B

2A to I

10A

3

2A to I

10A

4

2A to I

10A

5

5A to I

10A

6

10A to I

20A

* I

FLC

is the value of I

FLC

for OLR#2 if F3 is not set to OFF. If F3 is

OFF, I

FLC

is the value of I

FLC

for OLR#1.

Table 3.6 Ground fault pickup levels

Ground fault detection requires no additional external circuitry

or transformers. Ground fault detection for the SAMMS-LV

device is not available for grounded, three-phase systems or

single-phase applications. Ground fault pickup time is 360

msec.

3.25 Autoreset After a Trip (SAMMS-LVX

Only)

To restart the motor after a trip or a fault, you must first reset the

SAMMS-LVX device. You can reset the SAMMS-LV device in

one of two ways. First, press the Reset/Test button on the front

panel of the device. Second, enable the autoreset with HHC

function F8.

•

enable = ON

•

disable = OFF

With autoreset enabled, overload and external trips automati-

cally reset in 30 seconds after the trip. Once the reset occurs,

the SAMMS-LV device can be used to restart the motor, unless

the motor has reached its maximum temperature and has not

cooled down to the full-load level (start inhibit). Resetting after

a trip does not interrupt or otherwise affect the ongoing motor

thermal computations.

3.26 Emergency Restarting

In certain critical applications, you may want to restart a hot

motor even though restarting will damage or destroy the motor.

An emergency restart is a motor start that occurs after an

overload trip on maximum allowable winding or housing tem-

perature; but before they have cooled down to the full-load

temperature level (100%) or below. In other words, an emer-

gency restart is a start that occurs before the restart time

displayed by HHC function F10 reaches zero.

With the emergency restart function enabled (HHC function

F11), the motor can be restarted regardless of the residual heat.

If the SAMMS-LV device performs an emergency restart, the

winding and housing temperatures in the motor model compu-

tations reset to zero. Any time the motor is started, whether an

emergency restart or a normal start, the emergency restart

HHC function F11 is automatically reset to disable.

•

enabled = ON

•

disabled = OFF

3.27 Using the Hand Held Communicator

(HHC)

The HHC provides you with the capability to monitor and alter

various motor control and protection functions provided with

the SAMMS-LV device. For example, you can monitor and alter

control and protection settings such as on-delay time and

overload class. You can also monitor a variety of motor

operating conditions such as average current and elapsed

running time.

The SAMMS-LV device functions accessible through the HHC

are shown in Table 3.7 The number of functions available

depends upon the model of the SAMMS-LV device you are

using.

The HHCs small size makes it convenient to carry around and

use for communication with many SAMMS-LV devices. To use

the HHC, connect the HHCs cable, which uses a DB-9

connector, to the communication port located on the front

panel of the SAMMS-LV device. The HHC receives power and

control from the SAMMS-LV device. When connected to the

SAMMS-LV device, data is displayed on the HHC by a four-

character, seven segment liquid crystal display. When discon-

nected from the SAMMS-LV device, the HHC does not retain

or display data.

Once connected, you can access the functions provided by the

SAMMS-LV device through the use of the HHCs control keys.

The HHC has five (5) control keys: (F)unction, LIST, UP, DOWN,

and ENTER. The asterisk (*) key serves no function. The HHC

control keys are described in the following sections.

FLC

*

FLC

*

FLC

*

FLC

*

FLC

*

FLC

*

FLC

*