Vsph, Ictory, Equipment dimensions ratings – Slant/Fin VSPH-120 User Manual

Page 7: Ratings for natural and l.p. gas

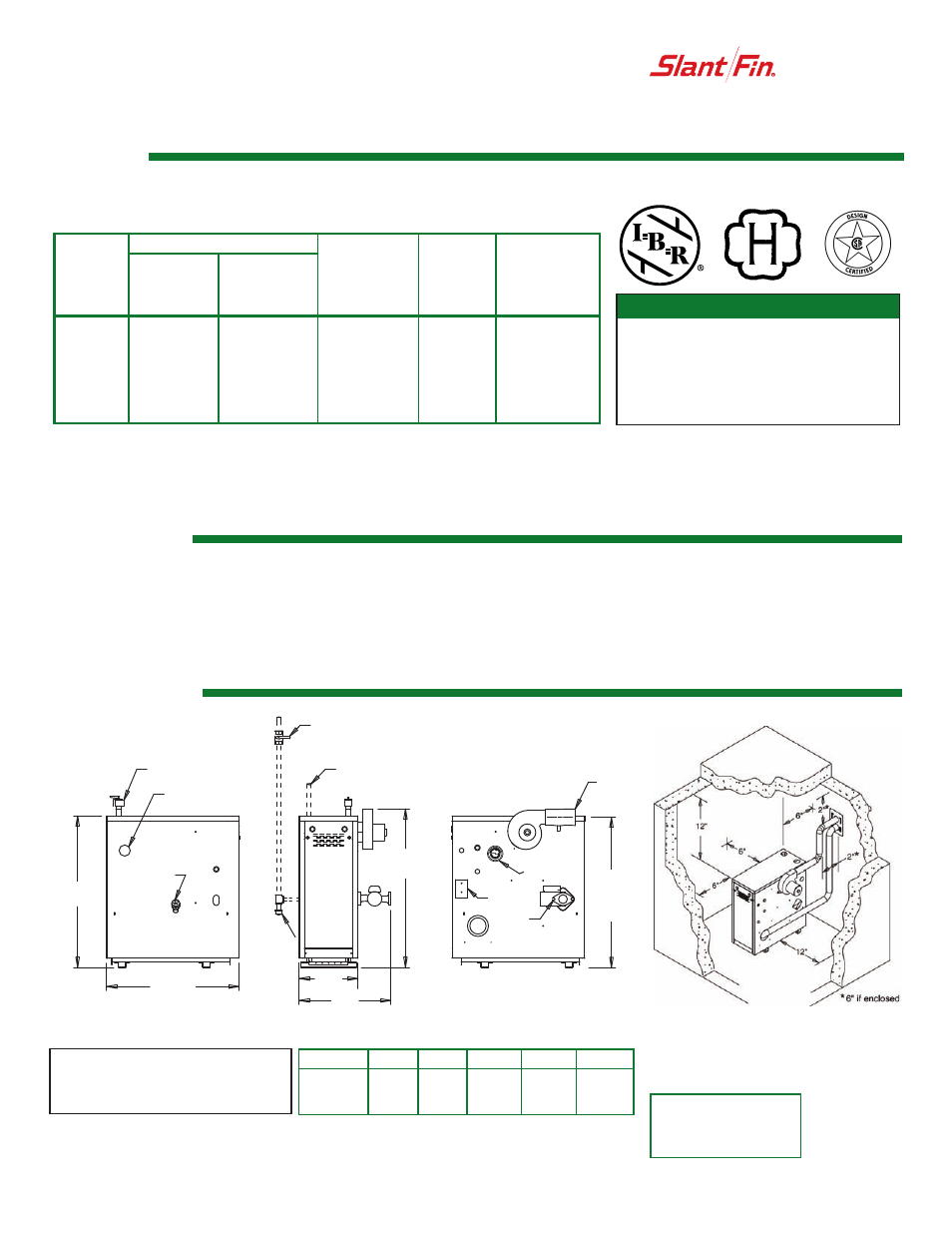

Dimensions VSPH-60 VSPH-90 VSPH-120 VSPH-150 VSPH-180

“A”

11

1

⁄

8

"

14

1

⁄

8

"

17

1

⁄

8

"

20

1

⁄

8

"

23

1

⁄

8

"

“B”

17

3

⁄

8

"

20

3

⁄

8

"

23

3

⁄

8

"

26

3

⁄

8

"

29

3

⁄

8

"

Pressure relief

valve

1

1

⁄

2

" FPT

supply

Install manual main

shutoff valve 5' above

floor when required by

local code

3

⁄

4

" to air eliminating

system

Dotted gas piping

by others

3" dia.

vent

connector

Press/temp

gauge

Junction

box

1

1

⁄

2

" return tapping

1

1

⁄

4

" cir. flange

Vent

connector

28

1

⁄

2

"

(See note)

28

3

⁄

4

"

(See note)

3

⁄

4

" Drain

25

1

⁄

8

"

(See note)

A

Jacket

B

Sediment

trap

required

30

1

⁄

2

"

(See note)

RIGHT SIDE

LEFT SIDE

FRONT

NOTE: Height dimensions increase by 1

1

⁄

2

" and

depth increases to 28

1

⁄

2

" when combustible floor

kit is used.

† Ratings must be reduced by 4% at 2,000 feet elevation and an additional 4% for every

additional 1,000 feet elevation over 2,000 feet. Net ratings shown include allowance from

normal piping loss and pick-up load. For installations having unusual piping and pick-up

requirements, additional allowances should be made before selecting the size of boiler

required. Ratings are based on a piping and pick-up factor 1.15.

‡ Based on heat emission rate of 150 Btu per square foot.

Note: All VSPH boilers are tested and rated for capacity under the U.S. Dept. of Energy

(D.O.E.) Test Procedure for Boilers

Maximum ASME working pressure: 50 psi..

PACKAGED WATER BOILER includes pre-assembled cast-iron heat

exchanger with built-in air eliminator, base, pre-assembled insulated flush

jacket, gas burners, gas orifices and manifold assembly, combination gas

valve, including manual shut-off, pressure regulator and pilot adjustment,

integrated boiler control with built-in diagnostics, electronic intermittent pilot

ignition system, pressure and temperature gauge, pressure relief valve

(ASME), circulator 1-1/4", drain cock, inducer assembly, air flow proving

switch, built-in condensate drain, trap and stainless steel vent pipe adapter,

unitized vent/air intake terminal, rollout safety switch. For propane, specify

when ordering.

OPTIONAL EQUIPMENT: 24 volt thermostat. Air package consisting of

diaphragm expansion tank, fill and pressure reducing valve, and automatic

air vent. Combustible floor kit. AL 29-4C

▲

stainless steel venting material.

Equipment

Dimensions

Ratings

Before purchasing this appliance

read important energy costs

and efficiency information

available from your contractor.

Supply water tapping

1

1

⁄

2

"

Circulator return flange*

1

1

⁄

4

"

Gas tapping, natural or propane

1

⁄

2

"

▲

AL 29-4C is a registered trademark of Allegheny Ludlum Corp.

*When not equipped with circulator, boiler 1

1

⁄

2

" return tapping.

Victory

VSPH boiler minimum

clearances for combustible

construction

(See installation instructions for further details.)

RATINGS FOR NATURAL AND L.P. GAS

V

ICTORY

VSPH

™

SEALED COMBUSTION GAS BOILER

MAXIMUM EQUIVALENT FLUE LENGTH

VSPH-60, 90 & 120: 40 ft.

VSPH-150: 35 ft.

VSPH-180: 33 ft.

May differ for certain vent system manufacturers and

altitudes. Vent terminal does not effect calculation

of total equivalent length.

See installation instructions, Pub. VSPH-40.

RATINGS FOR WATER

A.G.A.

D.O.E.

NET I=B=R

NET

MODEL

INPUT

CAPACITY

WATER

WATER

EFFICIENCY

No.

(Btuh)

(Btuh)

(Btuh)†

(Sq. ft)‡

(A.F.U.E.)

VSPH-60

60,000

52,000

45,000

300

86.1%

VSPH-90

90,000

78,000

68,000

453

85.7%

VSPH-120

120,000

103,000

90,000

600

85.5%

VSPH-150

150,000

128,000

111,000

740

85.2%

VSPH-180

180,000

154,000

134,000

893

85.1%