Troubleshooting, Parts list, Parts diagram – Southbend SB1231 User Manual

Page 8

Troubleshooting

Symptom

Possible Cause

Possible Solution

The chuck has

hard spots or binds

completely.

1.

Jaw is in a poor position for

clamping.

1.

Re-install jaws for maximum engagement with jaw

slot and jaw screw.

2.

Lack of lubrication, rust, burr, or

metal shavings inside of chuck.

2.

Disassemble, de-burr, clean, and lubricate chuck.

3.

Broken tooth on the jaw or the jaw

screw.

3.

Disassemble chuck and repair/replace broken part.

The workpiece slips

in the jaws.

1. Incorrect jaw or workpiece clamping

position.

1.

Re-install jaws for maximum engagement with jaw

slot and jaw screw.

2.

Chuck is binding before full

clamping force is achieved, or a jaw

or jaw screw is binding.

2.

Chuck is loaded up with contaminants. Disassemble

and service chuck. Loosen and retighten the chuck

key several times to distribute lubricant.

3.

Cutting overload.

3.

Reduce cutting depth or feed rate.

Clamping accuracy

is poor.

1.

Workpiece improperly clamped or

workpiece is misaligned.

1.

Remove jaws, clean, de-burr, and re-install; verify

accuracy and recalibrate test/dial indicator.

2.

Chuck loose; mounting is off-center,

or is improperly seated.

2.

Remove chuck, clean and de-burr mounting; adjust

camlock studs, and re-install chuck.

Parts List

Please Note: We included this parts breakdown for service purposes only. Since many of the parts shown are machined to

each individual chuck, they may not be available as replacement items.

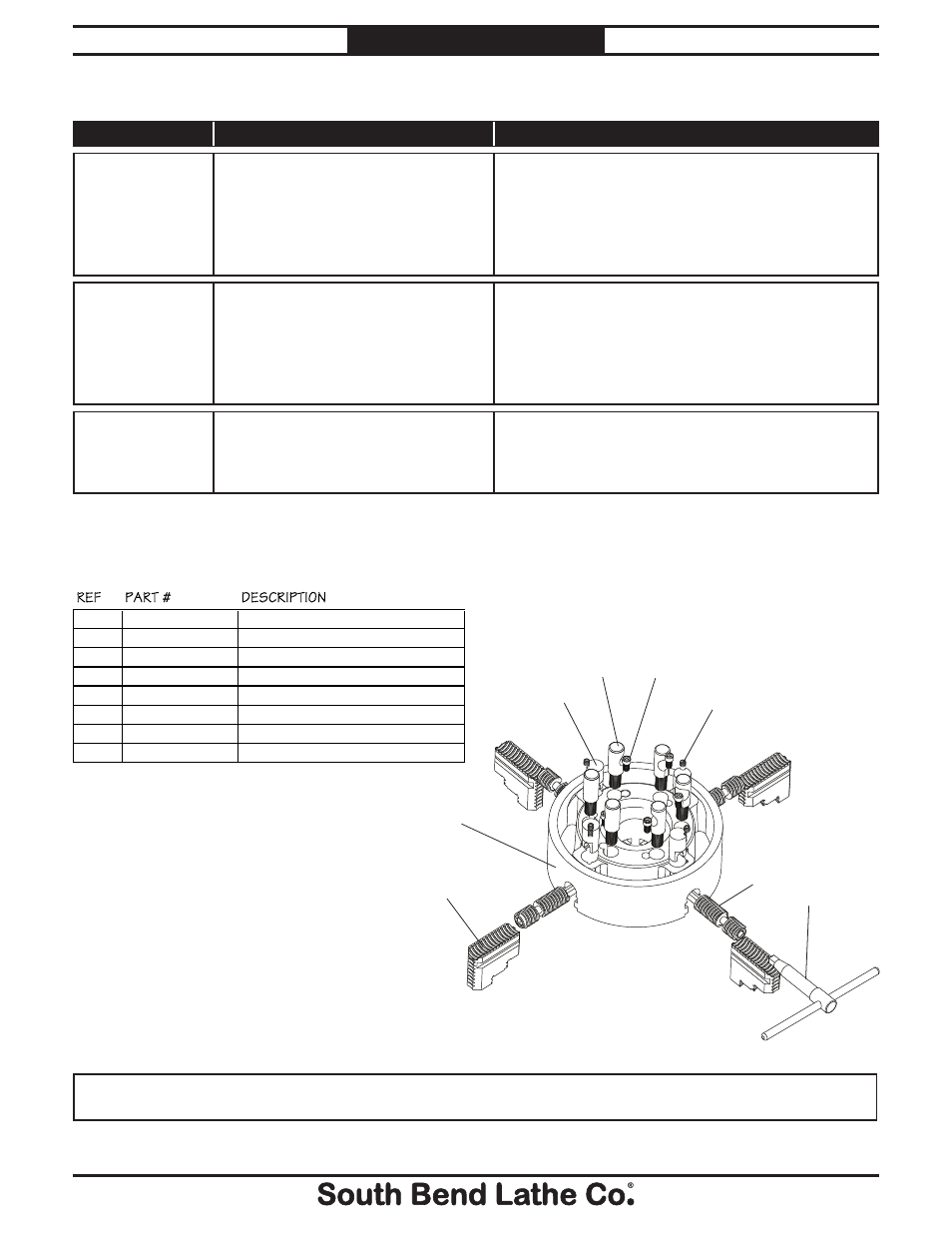

Parts Diagram

REF

PART #

DESCRIPTION

1

PSB1231001

REVERSIBLE CHUCK JAW

2

PSB1231002

CHUCK BODY

3

PSB1231003

JAW SCREW

4

PSB1231004

JAW SCREW PIN

5

PSS02

SET SCREW 5/16-18 X 3/8

6

PSB1231006

CHUCK KEY

7

PSB1231007

D1-8 CAMLOCK STUD

8

PCAP09

CAP SCREW 5/16-18 x 5/8

6

3

2

1

5

8

7

4

If you need help with your new chuck,

contact us at:

PHONE: (360) 734-1540

FAX: (360) 676-1075 (International)

FAX: (360) 734-1639 (USA Only)

EMAIL: [email protected]

-8-

Mfg. Since 5/10

Model SB1231

I N S T R U C T I O N S