Operation – Southbend SB1231 User Manual

Page 6

CAUTION: During the next step, the

chuck may come off suddenly, so it

is important that you are ready to

support its weight with a chuck cradle

to prevent crushing your fingers or

dropping the chuck.

4. Using a dead blow hammer or other

soft mallet, lightly tap around the outer

circumference of the chuck body to break the

chuck free from the camlocks and the spindle

nose taper.

5. Use a rocking motion to carefully remove the

chuck from the spindle.

— If the chuck does not immediately come

off, rotate the chuck approximately 60˚

and tap again. Make sure all the marks

on the cams and spindle are in proper

alignment for removal.

Operation

Non-cylindrical parts can be held and brought

into the spindle centerline for facing or boring

The other benefit is that the majority of

workpieces can be positioned out of the spindle

rotation axis if a bore (see Figure 9) or a step

needs to be cut into a workpiece on an outlying

edge. For the best grip possible on odd-shaped

workpieces, one or more jaws can also be rotated

180° to grab more surface area for clamping.

If all four jaws cannot be used to hold the

workpiece, you must use faceplate to reduce the

risk of a workpiece being thrown.

To clamp a workpiece in the chuck:

1. DISCONNECT LATHE FROM POWER!

2. Install a center in the tailstock.

3. Retract each jaw and place the workpiece

flat against the chuck face.

4. Slide the tailstock forward, so the tip of the

dead center applies enough pressure against

the workpiece to hold it in place, and then

lock the tailstock in position.

5. Move each jaw until it makes light contact

with the workpiece.

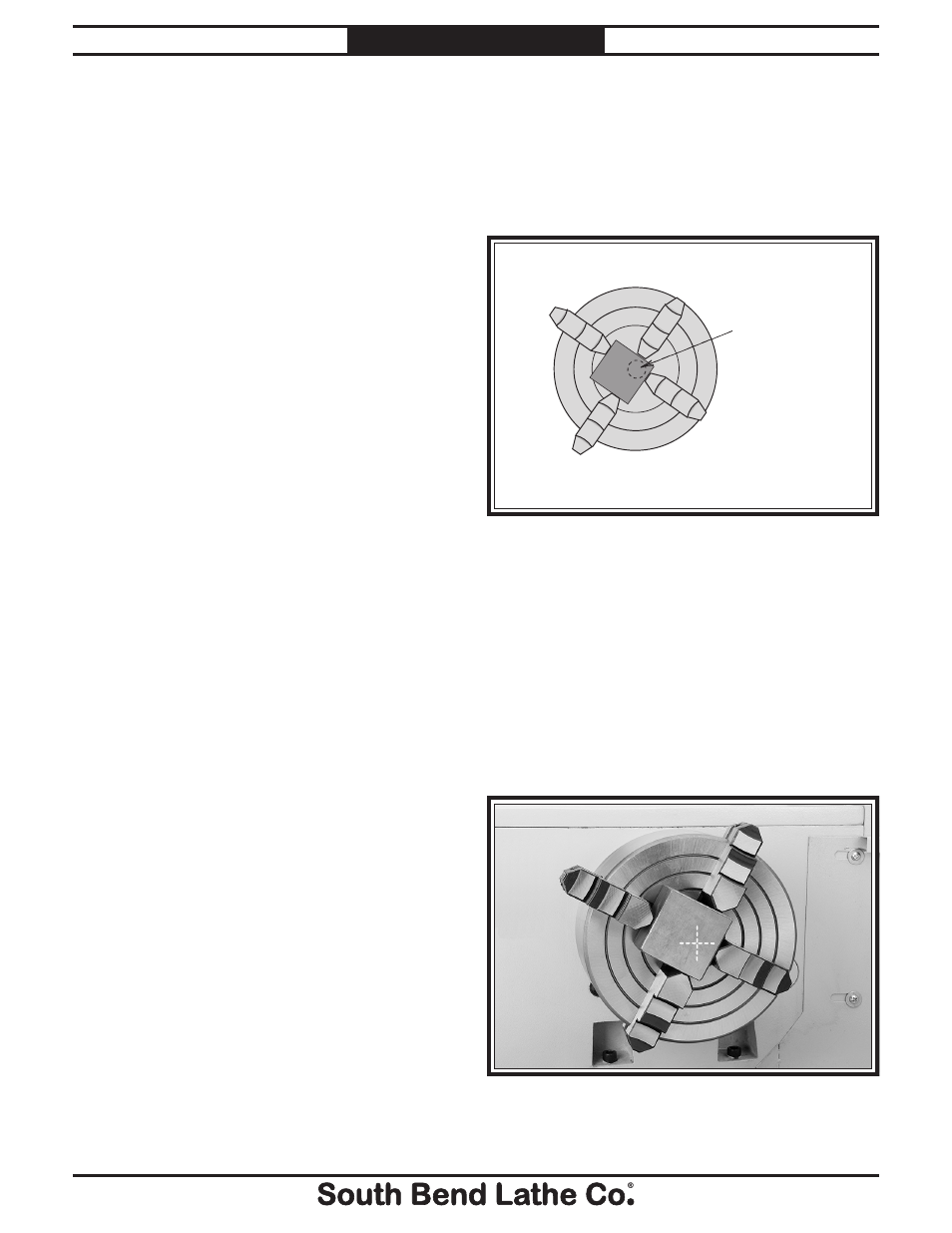

Figure 8. Tightening sequence.

7. After the workpiece is held in place by

the jaws, turn the chuck by hand and pay

attention to the workpiece alignment.

— If the workpiece is not correctly aligned

for your operation, turn the chuck and

make fine adjustments by slightly

loosening one jaw and tightening the

opposing jaw until the workpiece is

correctly aligned (see Figure 9 for an

example).

1

2

3

4

Hole to be

bored into

workpiece

Figure 9. Non-concentric workpiece correctly clamped

in the 4-jaw chuck.

6. Following the sequence shown in Figure 8,

tighten each jaw in small increments to move

the workpiece into the required position.

Check frequently to make sure the intended

center point of the workpiece has not

wandered away from the spindle centerline

while the jaws are being tightened.

-6-

Mfg. Since 5/10

Model SB1231

I N S T R U C T I O N S