Camlock stud installation, Camlock stud adjustment – Southbend SB1231 User Manual

Page 3

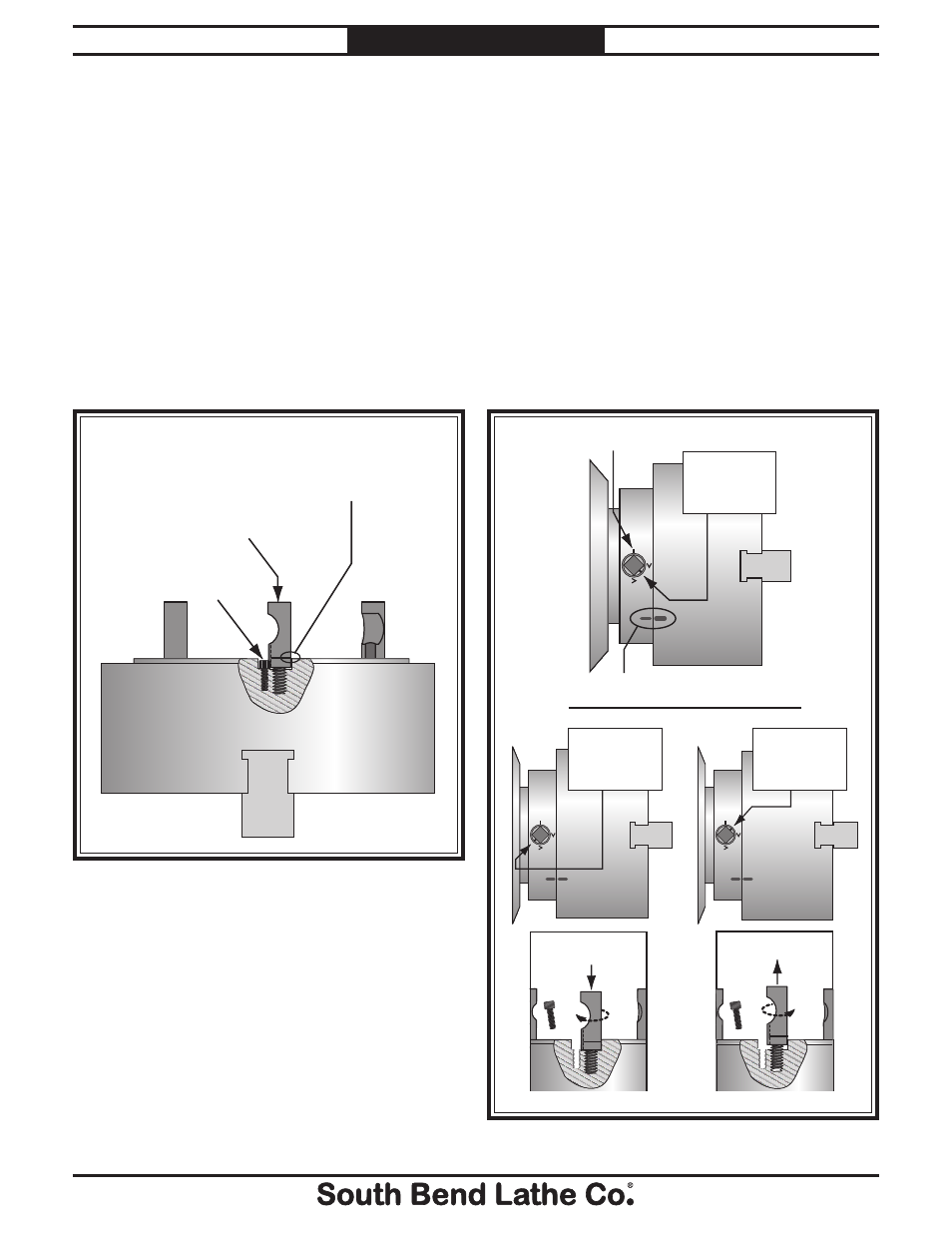

Camlock Stud Installation

The camlock studs that are shipped with this

chuck may be pre-installed from the factory.

If so skip this section and complete Chuck

Installation and Removal on Page 4;

otherwise, install the camlock studs as outlined

below:

1. Oil and thread each cam stud into the chuck

until the alignment groove is flush with the

chuck surface, as shown in Figure 2.

2. Install and tighten the locking cap screw

for each stud, making sure that the camlock

studs can slightly rotate back and forth.

Figure 2. Camlock stud installation.

Figure 3. Camlock stud adjustment.

Camlock Stud Adjustment

If the camlock studs have been pre-installed at

the factory, or if you are installing them for the

first time, slight machining differences between

the lathe spindle and chuck can cause one or

more camlocks to lock at the incorrect location.

If any cam line stops outside of a “V” mark when

all of the camlocks have been tightened, remove

the chuck and adjust the height of the offending

stud one full turn up or down as illustrated

below. After all camlocks operate correctly,

stamp alignment marks in the chuck and spindle

to ensure that the chuck can be re-installed in

the same position after being removed.

Camlock Stud

Must Slightly

Rotate Back/Forth

Cap Screw

Installed & Tight

Initial Adjustment:

Camlock Stud Alignment

Groove is Flush with Chuck

Surface

Alignment Marks

Spindle Line

CORRECT

The Camlock Mark

Stops Between the

“V” Marks.

To Correct:

Turn Stud One Turn In

To Correct:

Turn Stud One Turn Out

INCORRECT

The Camlock Mark

Stops Before the

“V” Marks.

INCORRECT

The Camlock Mark

Stops After the

“V” Marks.

Mfg. Since 5/10

Model SB1231

-3-

I N S T R U C T I O N S