11 cutter deck gearbox, 12 cooling system, Caution – Scag Power Equipment STT61V-25KBD-SS User Manual

Page 42: Warning

38

R

Section 7

CUTTER DECK GEARBOx

7.11

A. CHECKING LUBRICANT LEvEL

CAUTION

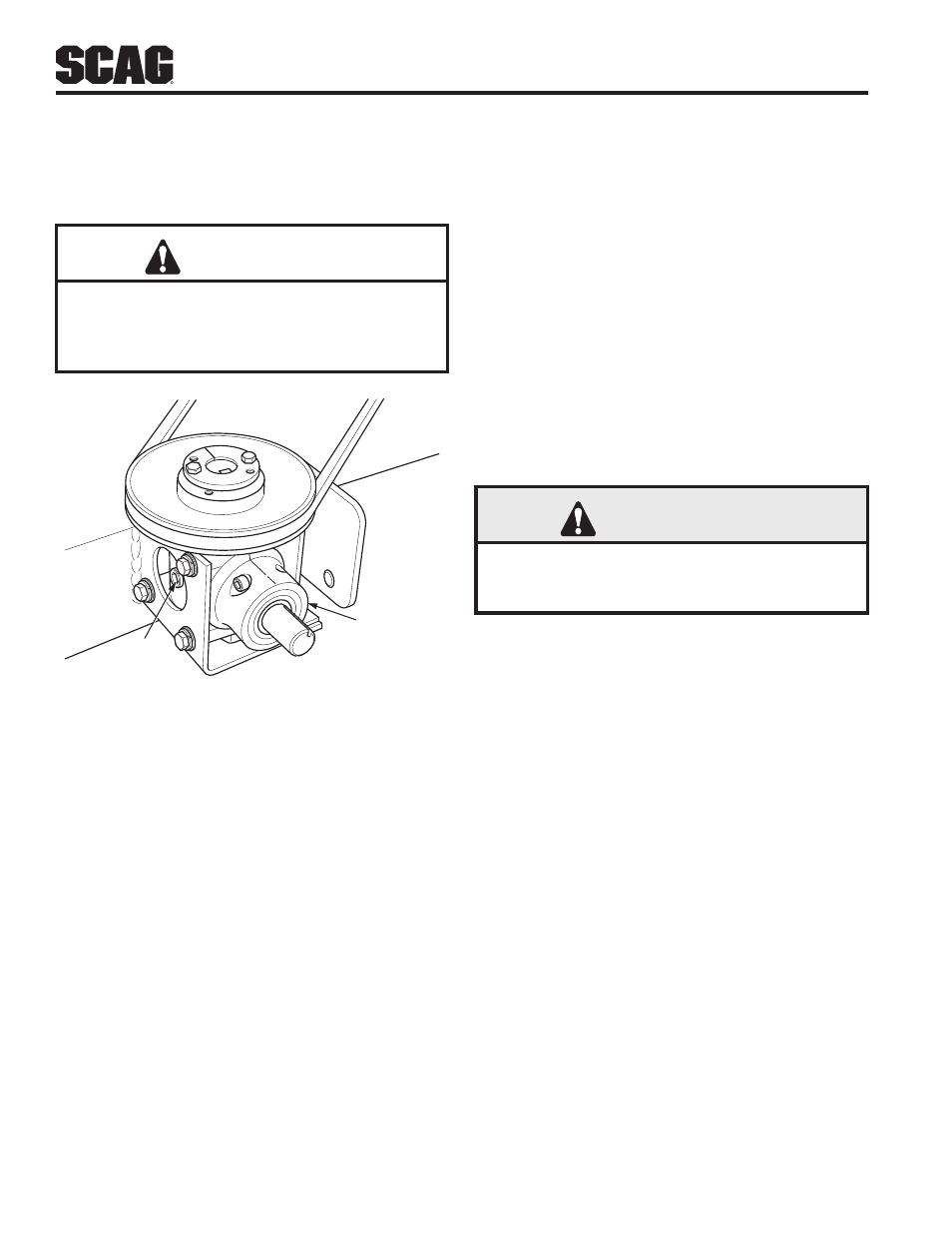

The cutter deck gearbox can reach high operating

temperatures. Allow the cutter deck gearbox to

cool before servicing.

390S0161

CUTTER DECK

GEARBOX

CHECK

PLUG

Cutter Deck Gearbox

Figure 7-8.

The fluid level in the cutter deck gearbox should be

checked after every 100 hours of operation or bi-weekly,

whichever occurs first. See Figure 7-8.

Lower the cutter deck to its lowest position to gain

1.

access to the cutter deck gearbox.

Clean and remove the check plug from the side of

2.

the gearbox. Visually check that the lubricant level

is up to the bottom edge of the check plug hole. If

lubricant is low, add SAE 80/90 lubricant through the

check plug hole in the gearbox until it is level with the

bottom of the check plug hole. Install the check plug

and tighten securely. See Figure 7-8.

B. CHANGING LUBRICANT

The lubricant in the cutter deck gearbox should be

changed every 500 hours of operation or yearly, whichever

occurs first.

Place a suitable container beneath the cutter deck

1.

gearbox and locate the gearbox drain plug.

Remove the drain plug and drain the lubricant into

2.

the container and properly discard it.

Re-install the drain plug and add EP-80/90 lubricant

3.

through the check plug hole in the gearbox until it is

level with the bottom of the check plug hole. Install

the check plug and tighten securely.

COOLING SYSTEM

7.12

WARNING

To avoid burns, always allow the engine to cool

before removing the radiator cap.

A. CHECKING COOLANT LEvEL

The coolant level should be checked before each day of

operation.

Remove the radiator cap by turning it slowly

1.

counterclockwise to the first stop and allow any

pressure to be released. Push down on the cap and

turn counterclockwise to remove.

Visually check the coolant level. The coolant level

2.

should be up to the bottom of the filler neck as

shown in Figure 7-9. Add a mixture of coolant and

soft water as needed.

- NOTe -

Refer to the coolant manufacturers's instructions

for the proper coolant mixture ratio.