2 lubrication – Scag Power Equipment STT61V-25KBD-SS User Manual

Page 35

31

R

Section 7

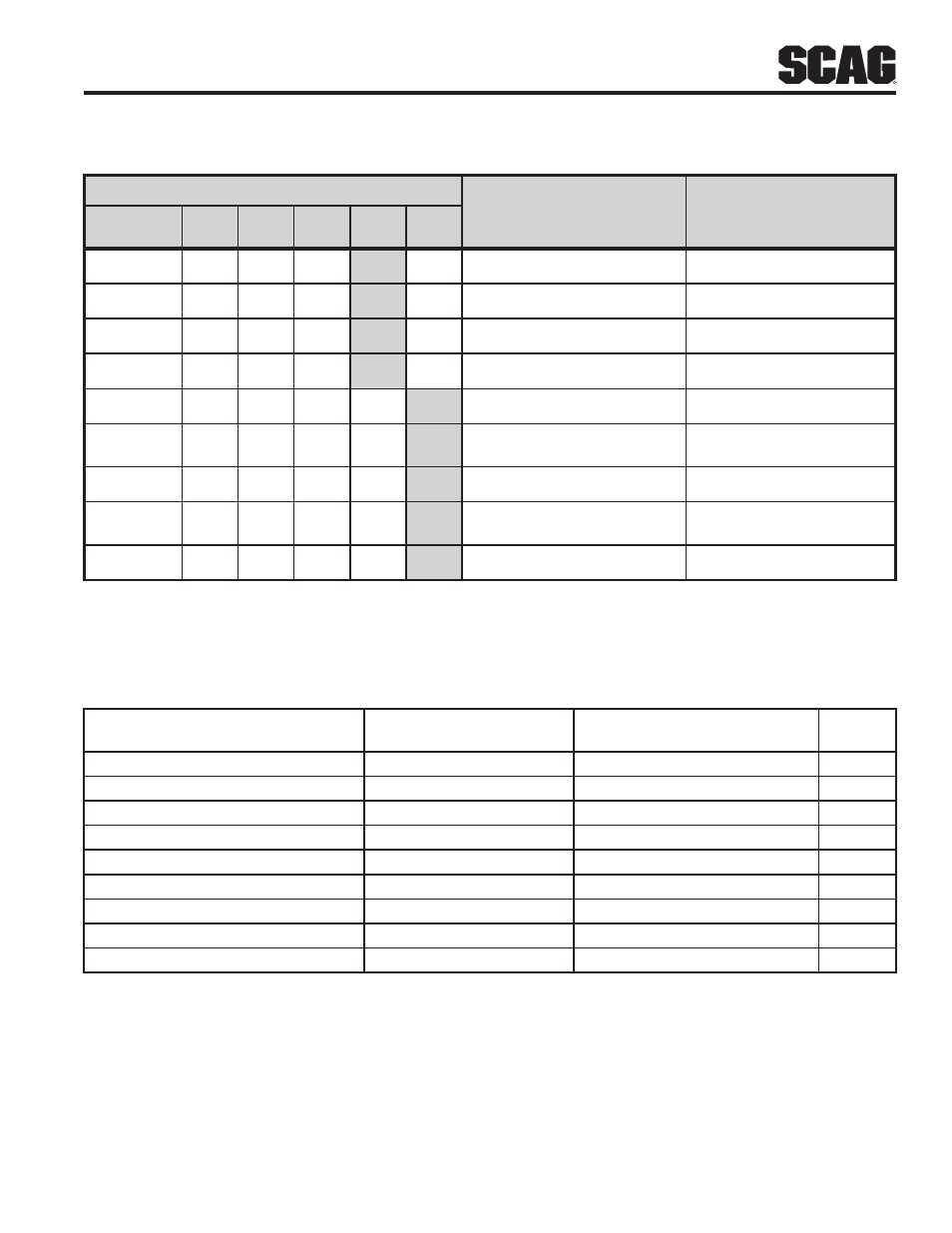

MAINTENANCE CHART - RECOMMENDED SERvICE INTERvALS (CONT'D)

HOURS

PROCEDURE

COMMENTS

BREAK-IN

(FIRST 10)

8

40

100

200

500

X

Apply grease to fittings

See paragraph 7.2

X

Check hardware for tightness

X

Change engine oil filter

See paragraph 7.4

X

Check hydraulic oil level

See paragraph 7.3

X

Replace engine fuel filter

See paragraph 7.5

X

Drain hydraulic system and

replace hydraulic oil

Use SAE 20W50 Motor Oil.

See paragraph 7.3

X

Replace hydraulic oil filter

See paragraph 7.3

X

Replace cutter deck gearbox

lubricant

See paragraph 7.11

X

Change coolant

See paragraph 7.12

LUBRICATION

7.2

GREASE FITTING LUBRICATION CHART (SEE FIGURE 7-1)

LOCATION

LUBRICATION INTERvAL

LUBRICANT

NO. OF

PLACES

1 Caster Wheel Pivot *

500 Hours/Yearly

Chassis Grease

2

2 Caster Wheel Bearings

100 Hours/Monthly

Chassis Grease

2

3 Brake Actuator

200 Hours/Monthly

Chassis Grease

2

4 Cutter Deck Bellcrank

40 Hours/Weekly

Chassis Grease

4

5 Cutter Deck Pusharms

100 Hours/Monthly

Chassis Grease

2

6 PTO Spindle

40 Hours/Weekly

+Lithium MP White Grease 2125

1

7 Cutter Deck Spindle

40 Hours/Weekly

+Lithium MP White Grease 2125

3

8 Brake Handle

200 Hours/Monthly

Chassis Grease

1

9 Cutter Deck Drive Shaft

40 Hours/Weekly

Chassis Grease

3

+ Compatible Greases:

Mobilix #2 found at Mobil Service Stations

Ronex MP found at Exxon Service Stations

Super Lube MEP #2 & Super Stay-M #2 found at Conoco Stations

Shell Alvania #2 found at Shell Service Stations

Lidok EP #2 found at industrial shops

* Remove plug and insert grease zerk. Before filling with grease, remove dust cap from the top of the pivot.