Warning, Cutter deck belt adjustments – Scag Power Equipment SWZ User Manual

Page 7

5

If you are not familiar with the operation of the

hydrostatic drive and zero turn feature, practice

turning and maneuvering with the hand controls

before engaging the blades.

5. Release the parking brake. Move the speed

adjustment lever to the desired mowing speed.

-NOTE-

Top speed is suggested only for transport!

6. While squeezing the steering brake levers with

both hands, release both neutral latches.

7. When the steering brake levers are released, the

machine will travel straight. To make a right

turn, squeeze the RH lever. To turn left,

squeeze the LH lever.

8. TO STOP, squeeze both levers, lock the neutral

latches, and move the speed adjustment lever to

neutral.

9. To move the machine in reverse, squeeze up on

both steering control levers.

10. To "freewheel" or move the machine around

without the engine running, turn the dump valve

levers located at the back of the pumps to the

"freewheel" positions.(see Figure 1). To operate

the machine the dump valve levers must be

returned to the closed positions.

ire pressure can be adjusted for

WARNING:

Dump Valve Levers

(normal position)

SGB112

Figure 1 Dump Valves

CUTTER DECK BELT ADJUSTMENTS

-NOTE-

The hydro drive belt is spring loaded and does

not require adjustment.

1. Remove the belt cover.

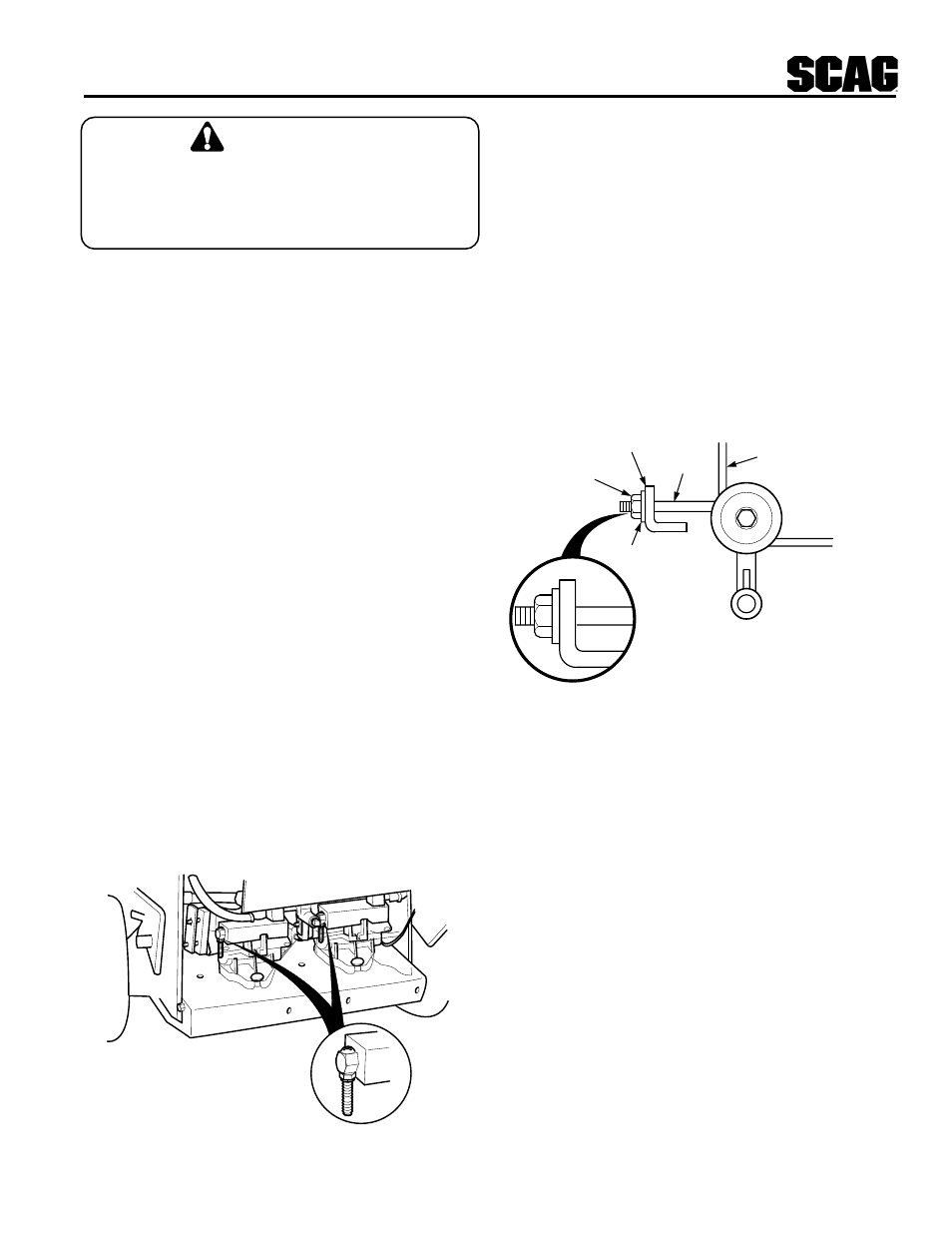

2. Adjust the cutter deck drive belt using a belt

tension gauge. Adjust the belt so that the belt

moves 1/2" with 10 pounds of pressure. Adjust

the tension by tightening or loosening the J-bolt

nut. (See figure 2)

SC400G

BELT

WASHER

"J" BOLT

NUT

CUTTER DECK DRIVE BELT TENSION

ALIGNMENT IDLER - L.H.

END OF L-SHAPED

BRACKET

Figure 2 Deck Drive Belt Adjustment

-NOTE-

Due to initial belt stretch and to prevent the belt

from slipping, check this adjustment after the

first 2 hours, 4 hours and 8 hours of operation.

3

.

Adjust the RH blade drive belt using a belt

tension gauge. Adjust the belt so that the belt

moves 1/2" with 10 pounds of pressure. Adjust

the tension by tightening or loosening the J-bolt

nut. (See figure 3)