Southbend Turn-nado Gearhead Lathe w/ Dro 21" x 60" sb1046pf User Manual

Page 58

-56-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

O P E R A T I O N

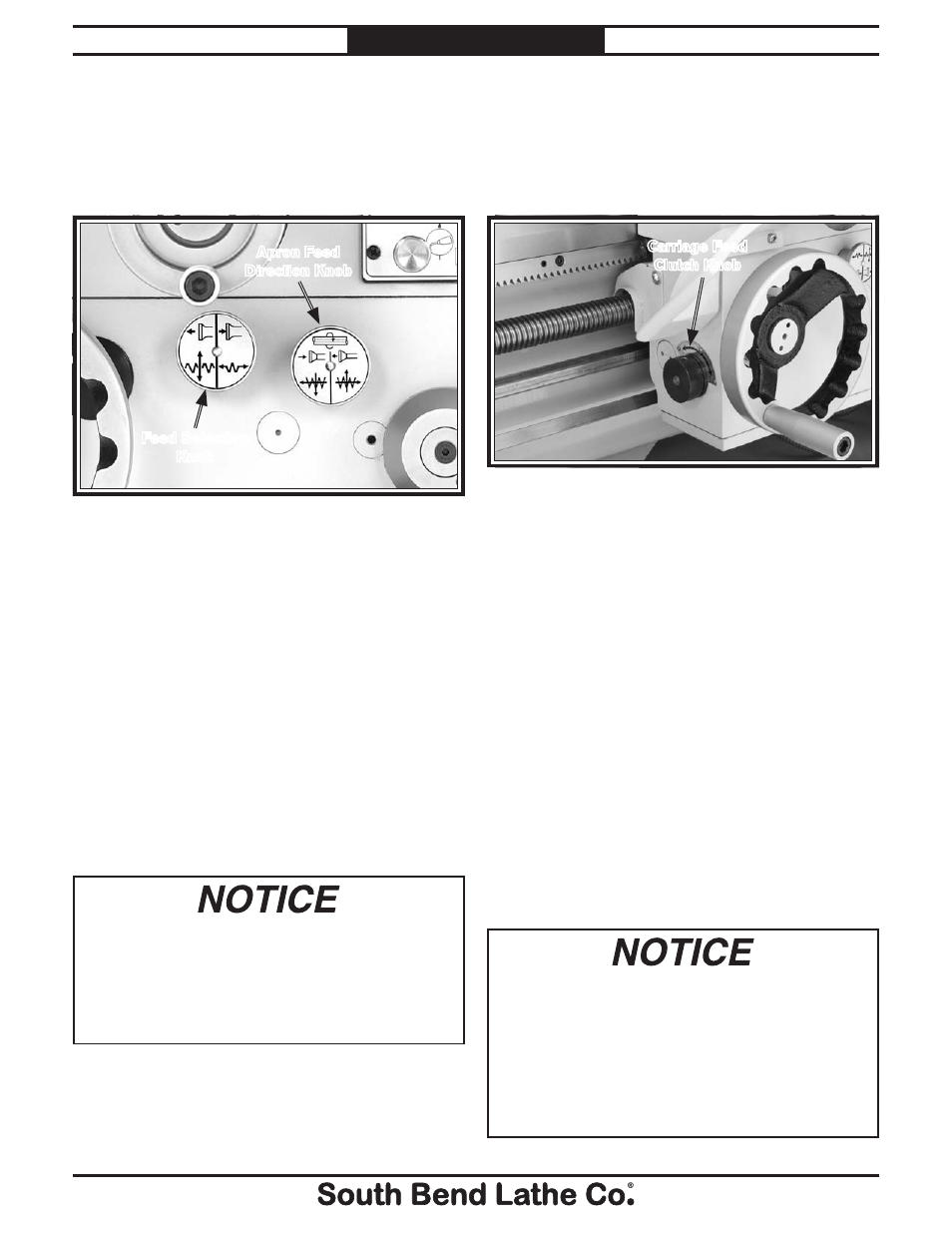

Feed Selection Knob: Selects the carriage or

cross slide for power feed (see Figure 70).

When the knob is pulled out, the cross slide is

selected. Conversely, when the knob is pushed in,

the carriage is selected.

Figure 70. Apron feed selection and direction knobs.

Feed Selection

Knob

Apron Feed

Direction Knob

In the middle position, the apron gears are

disengaged from the feed rod and neither

component will move.

Note: When using this control, you may need

to rock the handwheel of the component being

engaged so that the apron gears will mesh.

Apron Feed Direction Knob: Changes power feed

direction (see Figure 70),

When pushed in or pulled out, this knob quickly

reverses the power feed direction while the

spindle is rotating—without having to turn the

lathe off and use the feed direction lever on the

headstock.

Depending on the combined configuration

of the feed direction lever on the headstock

and the feed direction knob on the apron,

the actual direction of power feed may be

different from the printed indicators on the

machine!

Carriage Feed Clutch Knob: Adjusts how easily

the carriage clutch will disengage automatic

feeding when the carriage contacts a feed stop or

in the event of a crash. Tightening this knob all

the way disables the carriage clutch completely

(see Figure 71).

The carriage clutch serves two purposes: 1) It

disengages the carriage feed when the carriage

contacts a feed stop, providing a precise

repeatable stopping point; and 2) it provides

a safety factor in the event of an accidental

overload or crash.

The correct carriage clutch setting will depend

on variables of the operation, such as workpiece

material, depth of cut, power feed rate, and

others. Finding this clutch setting is a matter of

trial-and-error and experience.

For a starting point of clutch adjustment, rotate

the carriage feed clutch knob clockwise until it is

tight, then back it off counterclockwise three full

revolutions. This is a reasonably conservative

setting to start with. If necessary, further adjust

the knob for the setting that is right for your

operation.

The carriage clutch will not stop carriage

movement when it is engaged with the

leadscrew for threading.

If the carriage feed clutch knob is completely

tight (all the way clockwise), it will be

disabled, which will not allow it to help

prevent damage in event of a crash.

Figure 71. Adjustable carriage feed clutch knob.

Carriage Feed

Clutch Knob